I am in the middle of the AVCC (AudioVox Cruise Control) install on my 1st gen, and since I couldn't come up with anything more elegant for attaching the servo control cable to the throttle I followed the standard instructions of drilling the tab and installing the screw to hold the ball chain end fitting. BTW - thanks to Ionbeam for suggesting that the tab could be drilled without removing the fuel rail. That saved a lot of grief.

Anyway, all was going along fine and I was almost ready to drop the tank when I noticed that the nut side of that screw actually sticks out of the tab far enough to contact the throttle cable at a large throttle opening, and actually inhibits the throttle from opening the last little bit. The way I noticed what was happening, while checking for any hangups with the servo cable, is that instead of feeling a nice solid stop when WOT was reached, I was feeling a "springiness" of the screw and nut contacting the tensioned cable.

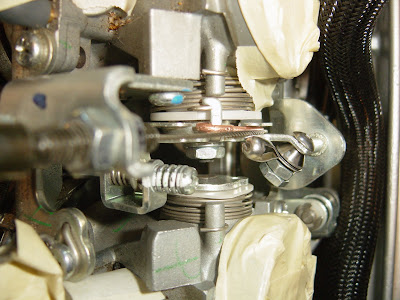

Here's a picture of mine:

I was able to slacken the cable and push it around the nut and there is about another 10 degrees of rotation before the hard throttle stops

Now, I'm sure that I could just leave it as is, especially since I spend so little time at WOT, and it doesn't look like it would skip over the cable and snag at WOT as it is. But the OC engineer wienie within will never be happy. It just isn't right.

So did anyone else that followed the standard install see this? Are all the FJR's with AVCC now full throttle limited?

Anyway, all was going along fine and I was almost ready to drop the tank when I noticed that the nut side of that screw actually sticks out of the tab far enough to contact the throttle cable at a large throttle opening, and actually inhibits the throttle from opening the last little bit. The way I noticed what was happening, while checking for any hangups with the servo cable, is that instead of feeling a nice solid stop when WOT was reached, I was feeling a "springiness" of the screw and nut contacting the tensioned cable.

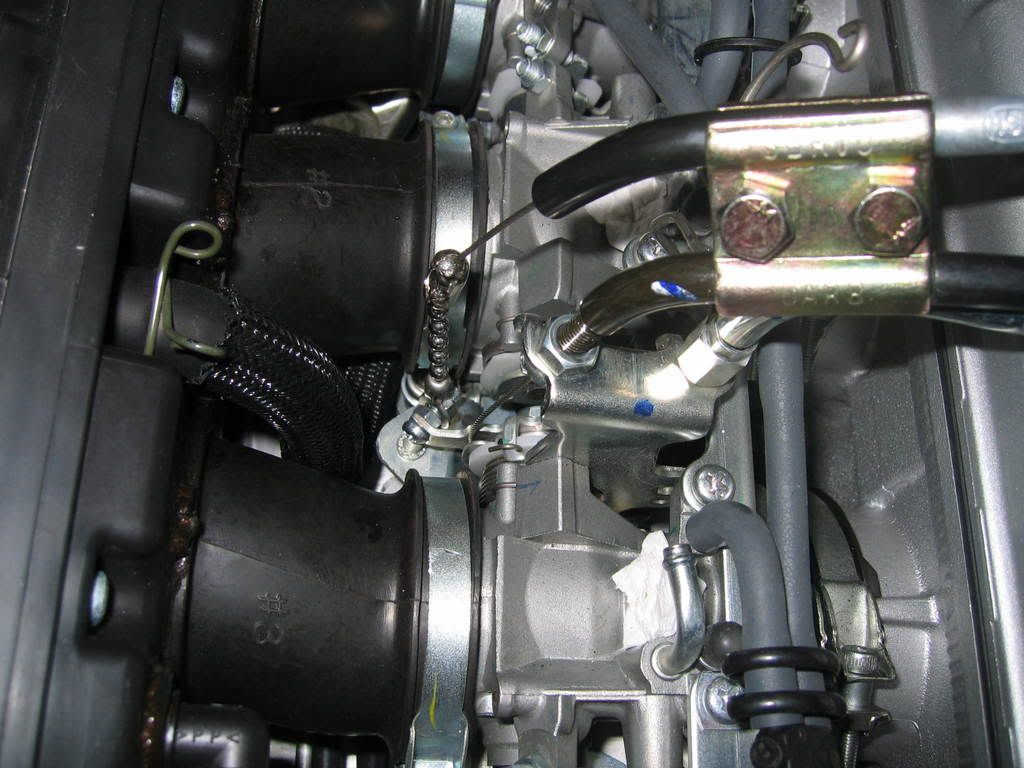

Here's a picture of mine:

I was able to slacken the cable and push it around the nut and there is about another 10 degrees of rotation before the hard throttle stops

Now, I'm sure that I could just leave it as is, especially since I spend so little time at WOT, and it doesn't look like it would skip over the cable and snag at WOT as it is. But the OC engineer wienie within will never be happy. It just isn't right.

So did anyone else that followed the standard install see this? Are all the FJR's with AVCC now full throttle limited?