NorthernRider

Member

I am a fairly new owner of an 05 FJR with around 32,000 miles on. The previous owner was the second owner and was uncertain of the maintenance history. Being the kind of guy that likes to know where a bike is at mechanically before putting on a bunch of miles I started in on the usual maintenance items which including checking the valves. One exhaust valve was measuring .005, cam comes loose (zip tied chain to both cams), new shim goes in, torque cam back down, release tensioner, rotate and things look off. Assuming the chain jumped a tooth I set off to fix the problem, problem is I can't seem to get it back to how the service manual shows. To add to the misery I am trying to do this with the engine in the frame.

Engine at TDC on #1 cylinder

Intake cam appears aligned

but also one tooth off compared to the exhaust

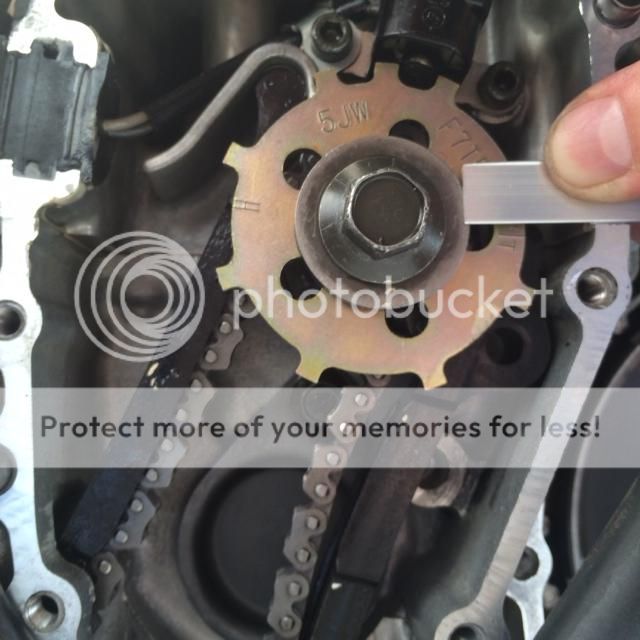

Teeth clearly not aligned

If I rotate a little further it past TDC

the cams align with one another.

If I set the cams first, put chain on exhaust cam and then around crank sprocket there is always a small amount of slack. This could be the source of my issues but I can not get the chain that apparent one tooth tighter than it needs to be. Seems like no matter what what I try I arrive at the same state of alignment. I'm about ready to throw in the towel and my riding season is drawing to a close. Any sage advice out there on what I am doing wrong?

Engine at TDC on #1 cylinder

Intake cam appears aligned

but also one tooth off compared to the exhaust

Teeth clearly not aligned

If I rotate a little further it past TDC

the cams align with one another.

If I set the cams first, put chain on exhaust cam and then around crank sprocket there is always a small amount of slack. This could be the source of my issues but I can not get the chain that apparent one tooth tighter than it needs to be. Seems like no matter what what I try I arrive at the same state of alignment. I'm about ready to throw in the towel and my riding season is drawing to a close. Any sage advice out there on what I am doing wrong?