DezzertRider

Well-known member

Hello,

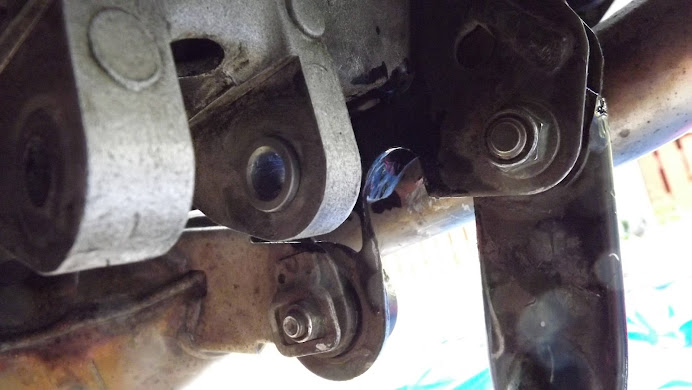

I'm doing all the pivot maintenance (lubing Swingarm, U-joint, shaft splines, relay arm bearings etc.) and need to remove the center stand to get the relay arm (boomerang) off.

I can't lift the bike from above because my garage has dry walled ceiling so I can't throw straps over the rafters etc.

What else can be used to lift the bike under the motor so that I can remove the center stand?

I have the rear wheel removed, shock removed and final drive. I'm not going to be putting the OEM shock back in after all this work. I'm looking at putting in an OHLINS YA052.

I'm doing all the pivot maintenance (lubing Swingarm, U-joint, shaft splines, relay arm bearings etc.) and need to remove the center stand to get the relay arm (boomerang) off.

I can't lift the bike from above because my garage has dry walled ceiling so I can't throw straps over the rafters etc.

What else can be used to lift the bike under the motor so that I can remove the center stand?

I have the rear wheel removed, shock removed and final drive. I'm not going to be putting the OEM shock back in after all this work. I'm looking at putting in an OHLINS YA052.