Chapter 2:

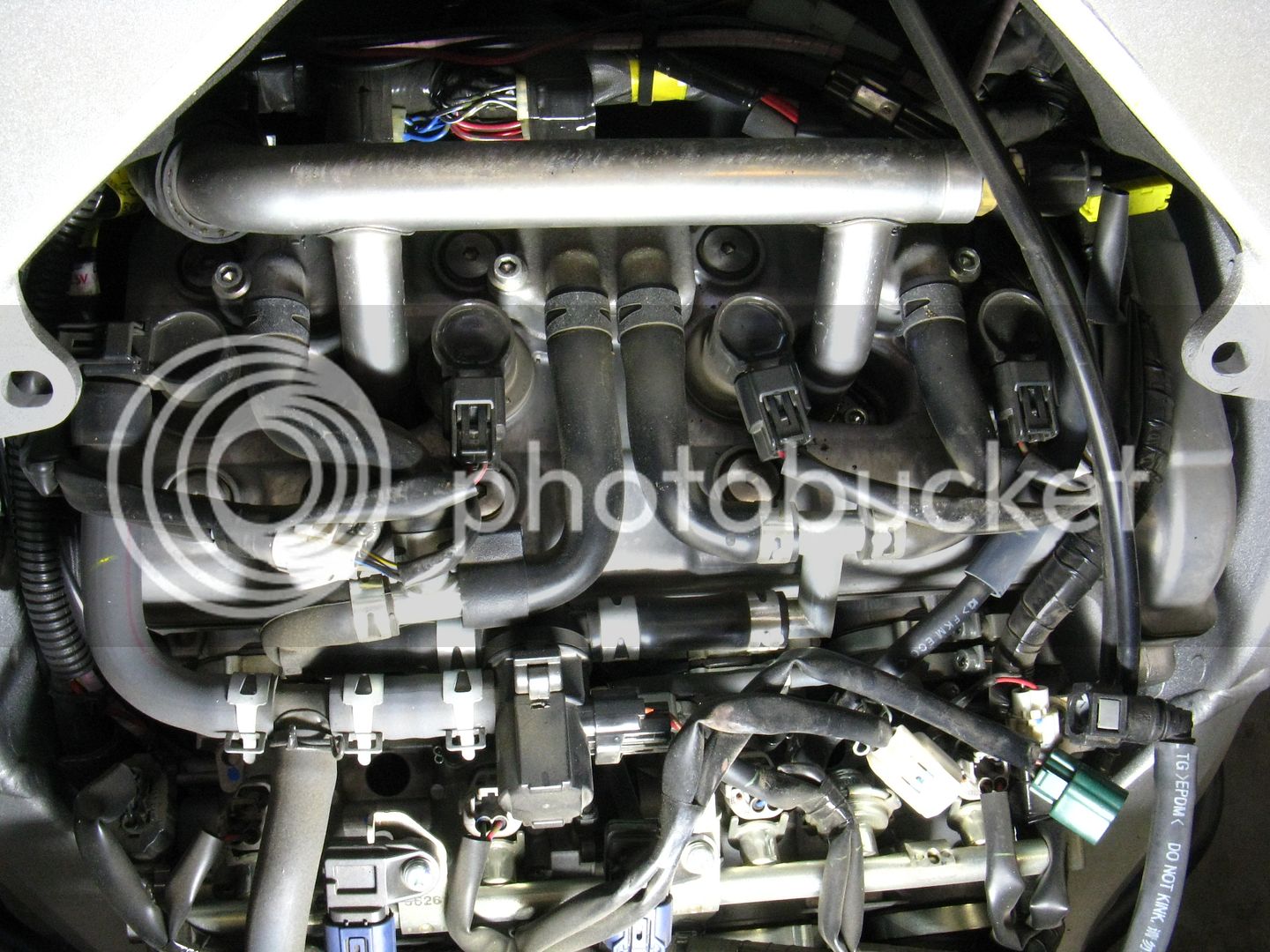

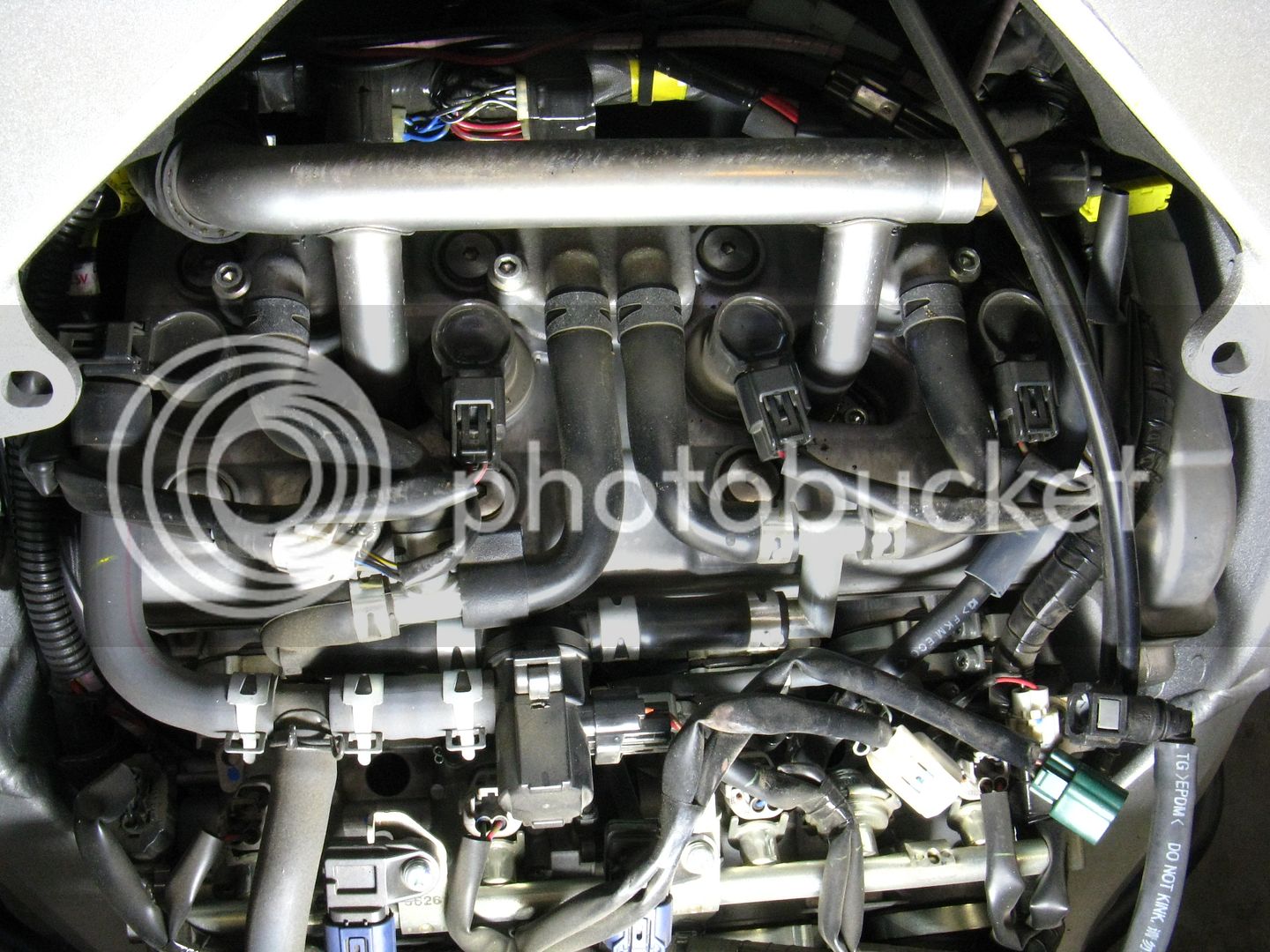

Today I worked on clearing the way to remove the valve cover. I followed rbentnail's advice on the coolant hose and that simplfied things enormously (thanks!). Those hoses were easier to take off than I thought they would be and it really made the next steps easier. Removing the PAIR valves and hoses is very straightforward, no complications there (they come off as a unit). In preparing to remove the valve cover, the biggest issues were a large harness that crosses from front to back right over the cam chain area and the throttle cables. Hard to see with all of the rest of the junk here but they are on the right in this picture:

I had to find the points that secured the harness (there are a couple), remove them so I could lift the harness. Next, I had to disassemble the throttle cable mounts at the throttle bodies:

These steps were necessary because the valve cover needs to be lifted and shifted aft in order to clear the cam chain sprockets. I though at first I could just lift and slide the cover out to the left but it hits the frame and prevents this. Once I was able to move the throttle cables and harness, I had room (barely) to wiggle the cover out.

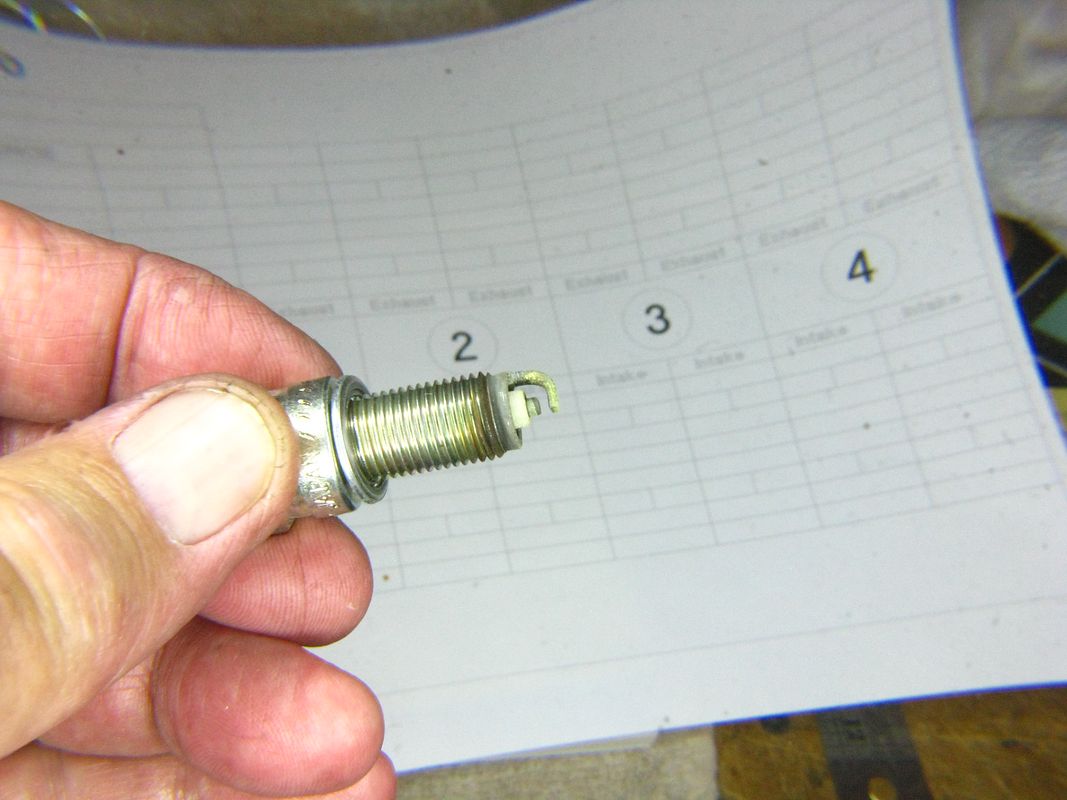

Now to the valves (specs are .006-.009 for intakes, .007-.010 for exhaust):

All of the intakes were at .007 except the left #4 valve which was at .008.

The exhausts were tighter. Here they are in sequence from left to right:

(loose) .007, .008, .008. .009, .009, .009, .008, .007.

As one can see I have two at the minimum clearance. If I were an enterprising soul, I would pull the exhaust camshaft and move those to the center. But I'm not going to do that, I'm okay with where they are at this point.

Spark plugs on the next post...

Dan