RossKean

Well-known member

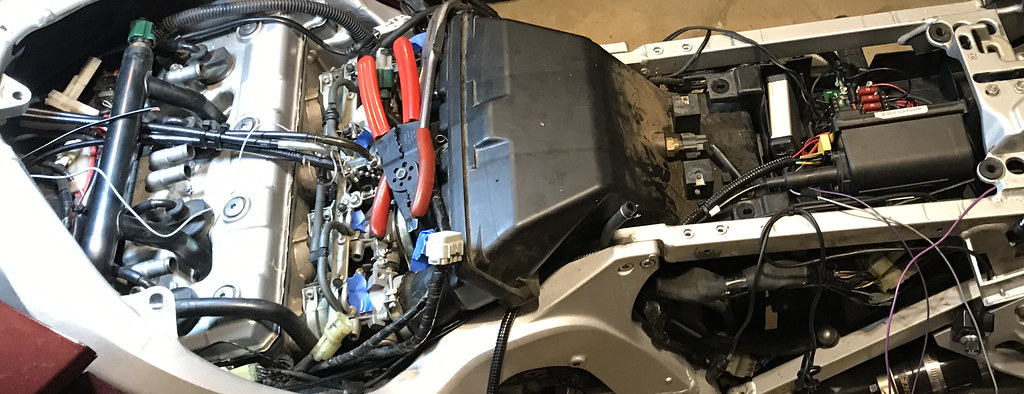

This isn't the first valve check and adjustment I have done although it is the first I have done on my 2011. Never had any problems in the past with my '07.

About 130,000 km on the bike (81,000 miles). Last check was done by previous owner at ~26,000 miles.

All exhaust valves were OK. Most of the intakes were right around the minimum (0.15-0.17 mm) but one (4-2) was closer to 0.12. With shim swapping, sanding a few and replacing two, I got everything in the range of 0.18 to 0.21 mm. Buttoned it up and today I added coolant and changed sparkplugs and decided to fire it up for a leak check.

Started very easily and did the normal fast idle. After it warmed up, the idle dropped a bit too low so I kept it running by applying a bit of throttle. As it got warmer (about mid scale), the engine started to bog down - almost like a cylinder was dropping out or running out of gas. Ran really crappy so I shut it down. It restarted just fine after a few minutes and ran for a minute or so before it started to bog down again.

No pinch in fuel line, tank venting properly, engine not overheated (based on temperature gauge). No codes came up on the dash although I haven't checked history yet.

I thought I was being really careful with cam timing. I zip-tied the chain to the cam sprockets and just moved the intake cam aside rather than removing it. Never had an issue doing it this way before.

Any ideas for me other than to take it all apart and see if I somehow managed to mess up valve timing? Would that cause it to run just fine cold but bog down when the engine heated up?

About 130,000 km on the bike (81,000 miles). Last check was done by previous owner at ~26,000 miles.

All exhaust valves were OK. Most of the intakes were right around the minimum (0.15-0.17 mm) but one (4-2) was closer to 0.12. With shim swapping, sanding a few and replacing two, I got everything in the range of 0.18 to 0.21 mm. Buttoned it up and today I added coolant and changed sparkplugs and decided to fire it up for a leak check.

Started very easily and did the normal fast idle. After it warmed up, the idle dropped a bit too low so I kept it running by applying a bit of throttle. As it got warmer (about mid scale), the engine started to bog down - almost like a cylinder was dropping out or running out of gas. Ran really crappy so I shut it down. It restarted just fine after a few minutes and ran for a minute or so before it started to bog down again.

No pinch in fuel line, tank venting properly, engine not overheated (based on temperature gauge). No codes came up on the dash although I haven't checked history yet.

I thought I was being really careful with cam timing. I zip-tied the chain to the cam sprockets and just moved the intake cam aside rather than removing it. Never had an issue doing it this way before.

Any ideas for me other than to take it all apart and see if I somehow managed to mess up valve timing? Would that cause it to run just fine cold but bog down when the engine heated up?