TomInPA

Well-known member

Another try at the high-res image..

About the time I took off my second one and got the cold shiver...I actually thought about that. Am I just a lucky fool or are two flange sides just fancy-schmancy overkill.Given that they break, people then ride with them for thousands of miles broken like that with no problems it looks like it just needs to be make with one flange

Maybe my shock was worn, but my rear tire was slipping and leaving the ground pretty often just before I pulled it and found it was broken. Handling went to hell after bike was airborne in VT on bridge construction whoop dee do and then landing really hard on the next whoop.Given that they break, people then ride with them for thousands of miles broken like that with no problems it looks like it just needs to be make with one flangeIt appears that the part could use a stress relieving process.

One flange will now have All the shear and tension on it probably making it crack faster and then not have the second flange as a failsafe. Not a good idea. :no:Given that they break, people then ride with them for thousands of miles broken like that with no problems it looks like it just needs to be make with one flangeIt appears that the part could use a stress relieving process.

Fred, that's normal for a failure like that one. It's relatively thick. Metal having a grain structure will not snap like a piece of glass. It's more like tearing apart like a piece of wood.Yes, the intent of the large diameter threaded stud coming out of the Clovis yoke is to allow some ride height adjustment. Having had your adjustment bottomed out should have put the least possible stress on the part.

One thing that appears in al, of the broken part pictures is an alarming amount of "grain" in the broken casting. I'll defer to one of the mechanical engineers but I wouldn't have expected to see so much striation of the metal crystals.

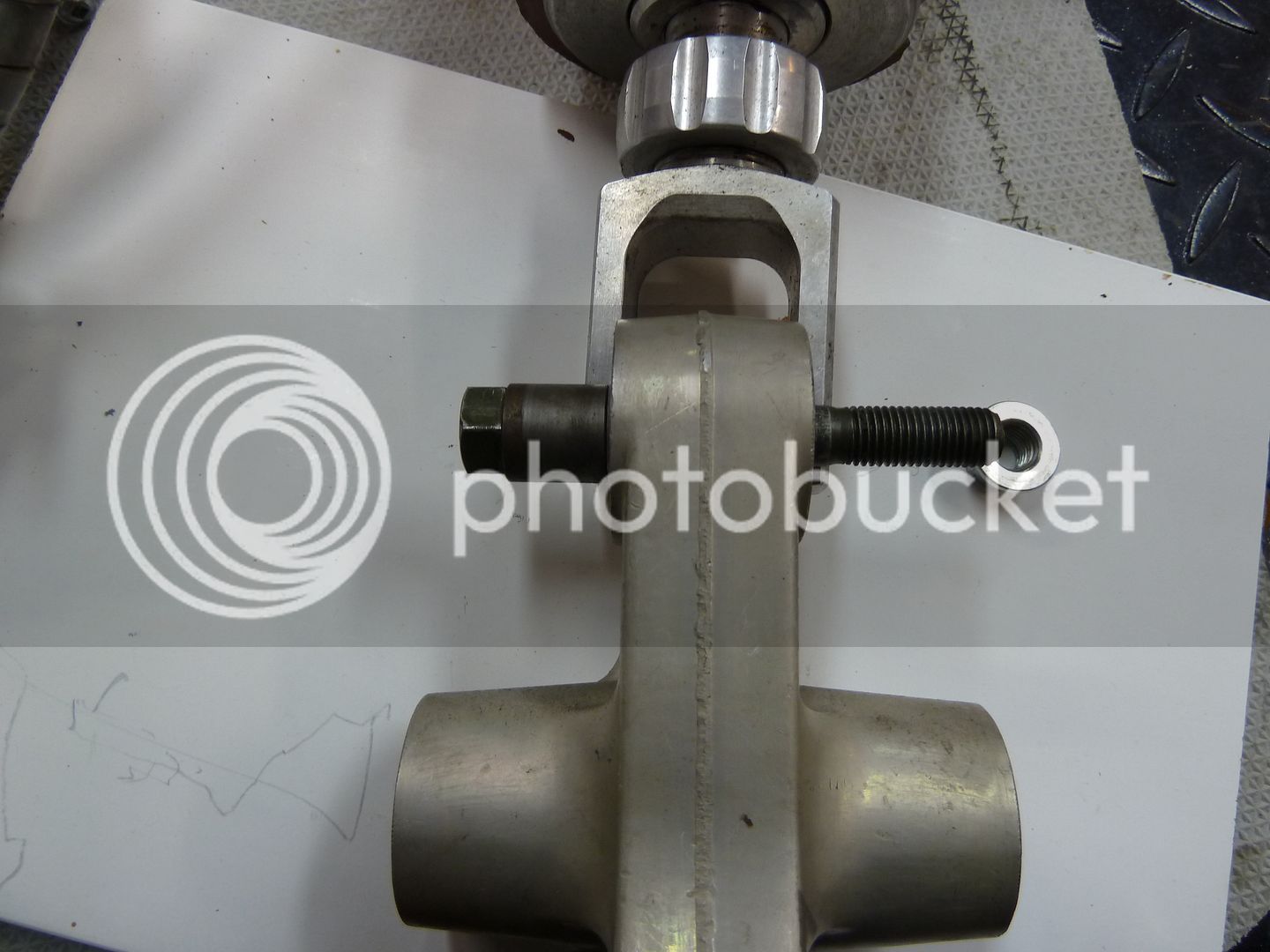

I suggested that earlier on, however, I re-thought that and I'm not so sure the washer idea is still a good one. Better to use the RaceTech bolt/spacer idea (spacer is 16 mm OD, 12 mm ID and 16mm long) doesn't have to be as long for sure, but anything longer than the OEM bolt's shoulder would be good. Otherwise, the thing to do is measure up the Penske clevis and Gen1/2 bolt shoulder, determine what's needed from there.Ray - thanks for the measurements. Like you, I was hoping for a delta of much closer to zero between the spacer width and the Clevis gap. I wonder what a washer to close the gap would do?

No, I would not add any shim (that's what it would be technically, not a washer) on the right side of your photo. I would put it on the left side, between the shoulder of the bolt and the inner bearing race.My reasoning for the washer idea and hesitation is this....... any washer on the right side (in my picture) pushes the pivot spacer left, so how much washer?

Enter your email address to join: