OGRE

Well-known member

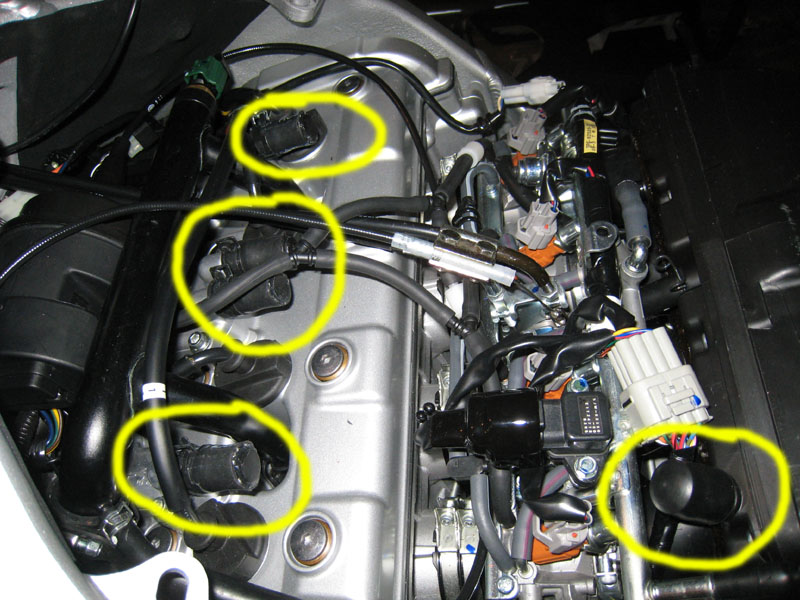

I removed the pulsed air injection system last November using this thread clicky as a guide. I chose to use the Dorman bypass caps to plug the ports on top of the engine.

Tonight when I lifted my tank to route wires for my new Starcom Digital I noticed that TWO of the plugs were split along their length and were allowing unmetered air into the exaust. The other two were showing signs of heat damage and starting to crack. If you used the dorman caps you may want to lift the tank and check!

Tonight when I lifted my tank to route wires for my new Starcom Digital I noticed that TWO of the plugs were split along their length and were allowing unmetered air into the exaust. The other two were showing signs of heat damage and starting to crack. If you used the dorman caps you may want to lift the tank and check!

Last edited by a moderator: