ToyQuest

Well-known member

I've grown tied of disassembling/reassembling the rear brake pedal just to keep it lubed. I decided to fix it for good when I had it off today.

The GenII rear brake pedal shaft is already counterbore from the back side making the fix pretty simple. (Not sure about the Gen 1 fitment)

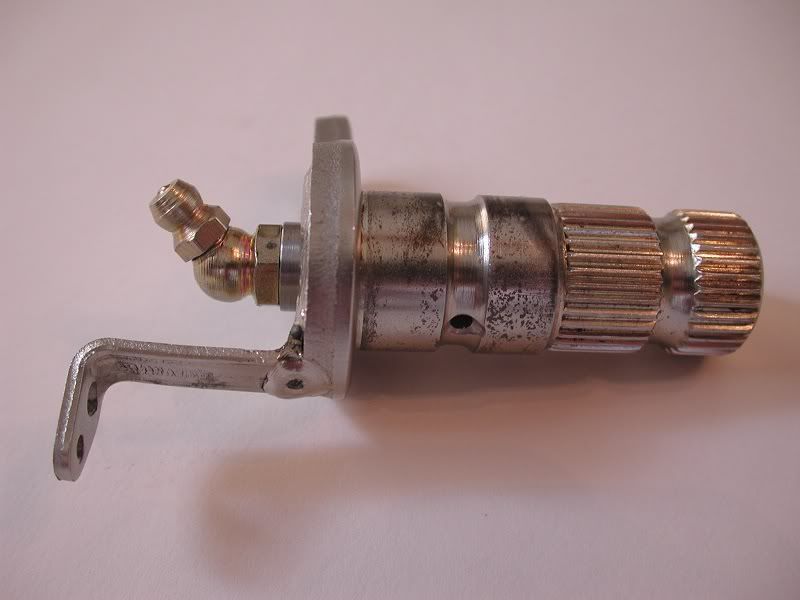

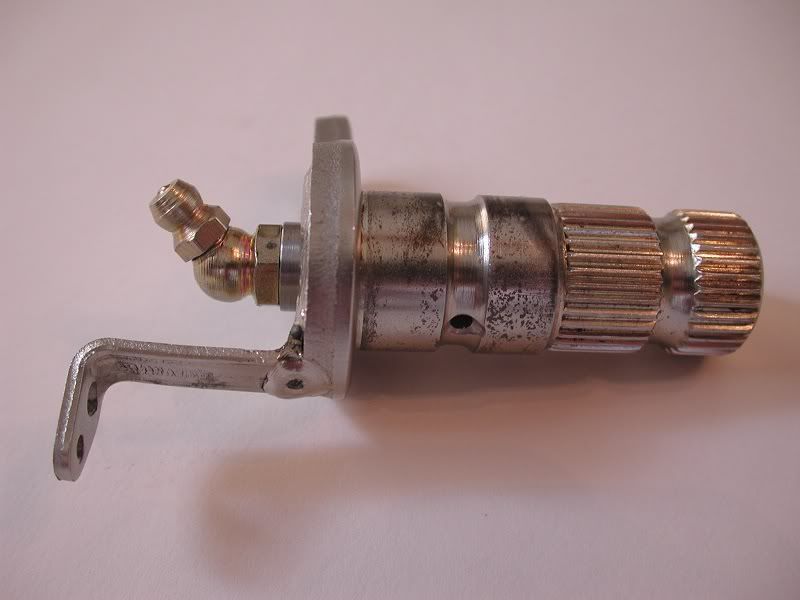

I turned down a press fit bushing to go into the pedal shaft counterbore. The diameter for mine pedal shaft counterbore was .394". I turned the bushing .397x.500 with a oversize lip and thread it for a 1/4x28 zerk fitting. I drill a single .100 hole in the shaft in the recessed lube carrier area.

It then was as simple as pressfitting the bushing, install the zerk fitting and reassembling - for the last time

Below are all of the pics. I did end up using a straight zerk fitting rather than the 45 degree one pictured here for optimal ease of use. Now it is a 10 second operation to lube the pedal.

Now time to one of the CNC owner/operators here to turn a batch down for everyone. Hint...Hint...

Brake pedal shaft, press fit bushing, zerk fitting

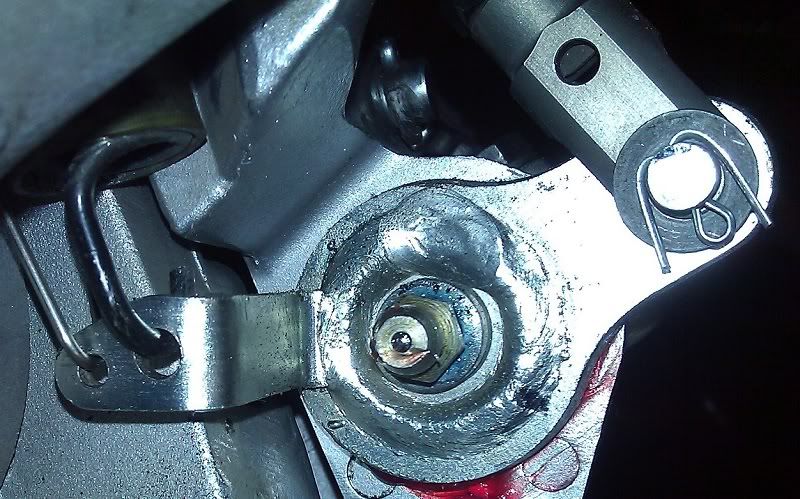

Before being pressed in

After being pressed in

Completed assembly with grease hole drilled

The GenII rear brake pedal shaft is already counterbore from the back side making the fix pretty simple. (Not sure about the Gen 1 fitment)

I turned down a press fit bushing to go into the pedal shaft counterbore. The diameter for mine pedal shaft counterbore was .394". I turned the bushing .397x.500 with a oversize lip and thread it for a 1/4x28 zerk fitting. I drill a single .100 hole in the shaft in the recessed lube carrier area.

It then was as simple as pressfitting the bushing, install the zerk fitting and reassembling - for the last time

Below are all of the pics. I did end up using a straight zerk fitting rather than the 45 degree one pictured here for optimal ease of use. Now it is a 10 second operation to lube the pedal.

Now time to one of the CNC owner/operators here to turn a batch down for everyone. Hint...Hint...

Brake pedal shaft, press fit bushing, zerk fitting

Before being pressed in

After being pressed in

Completed assembly with grease hole drilled