Last fall I had one hot running incident that caused me to shorten up a ride with

HERJR (12/3/12 -- now Iris on the Forum) because of bucking and lack of throttle response, after that episode it ran just fine. Early this spring I had another episode of buck/fart/misfire. About 6 weeks ago Feejer started to regularly be unpleasant when hot, exhibiting misfiring at some cruising speeds. Starting a few weeks ago it would sometimes become intolerant of slight throttle openings at idle. The symptoms occurred when very hot, > 3bars and radiator fan cycling on/off.

After a bad ride I checked the diAG screen but there were no codes set. I checked the values of all the sensors including the TPS and found nothing wrong. I was concerned about the delay between the misfiring and when I checked the TPS. Next time I experienced misfiring I pulled over and immediately shut down and invoked the diAG screen. Every thing was within spec. After restarting bikie it ran well. Next time it happened I shut off the key while going ~35 mph and entered diAG and ran tests while coasting down and found nothing out of spec.

Wellhell, time to get serious. This past weekend I pulled off the filler ring assembly

(procedure here) and found an amazing pile of road spooge that I cleaned out. I dissembled the ring and verified all vent passages were clear (1). I checked all hoses under the gas tank for pinching and obstruction. No problems found. A test ride quickly showed no cure. No surprise.

It becomes a bit more tricky to troubleshoot when everything passes the diAG test because those are the operating values that the ECU makes its calculations from. I did a bit of studying with the FSM and came up with a list of things to check.

Among the sensors, the TPS, atmospheric pressure sensor (here after APS) and intake manifold pressure sensor (IPS) were high on the suspect list. The pressure sensors include a integrated circuit (IC) that performs temperature compensation and linearization of signals. ICs don't tolerate heat well so they became suspects. Both atmosphere and intake sensors are the exact same part(!). I pulled them and verified that the sensor opening was not obstructed. DO NOT POKE ANYTHING IN THE SENSOR HOLE! DO NOT SQUIRT AN AEROSOL SPRAY IN THE HOLE! The active part of the sensor is very delicate. The APS operates over a very small range so it is unlikely to be a problem, the IPS has a wide dynamic range and it also bakes under the tank making it a likely suspect. Since the sensors are the same I swapped them to see if the problem was either cured or changed. A test ride quickly showed no change, no cure.

Next --- > I used my fuel pressure gauge and mity-vac to test the fuel pressure regulator. No problem. At least at room temperature. I put a Tee on the intake manifold vacuum line that controls the fuel pressure regulator, ran a vacuum line up to the dash and put on a vacuum gauge. Ride time. Upon misfire it was clear that the change in manifold vacuum was a consequence of the misfire and not a leading cause (2). This pretty much lets out the fuel injectors, fuel pump and pressure regulator. This is the first time that I started to really consider that the problem might be electrical ignition.

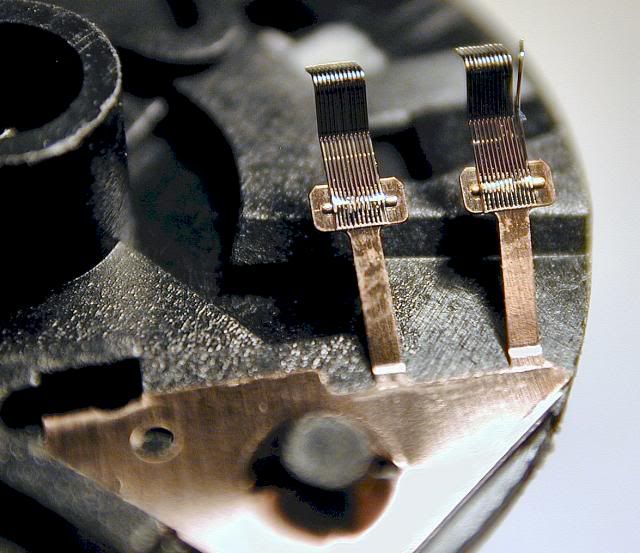

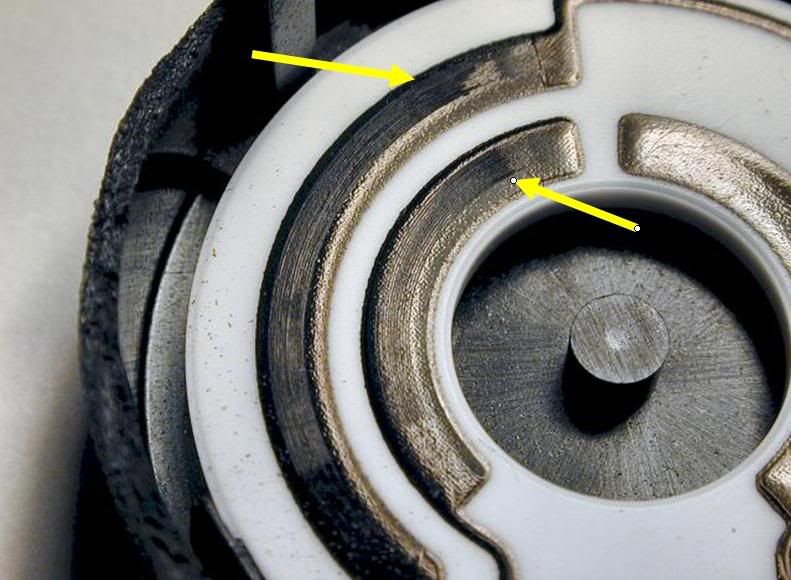

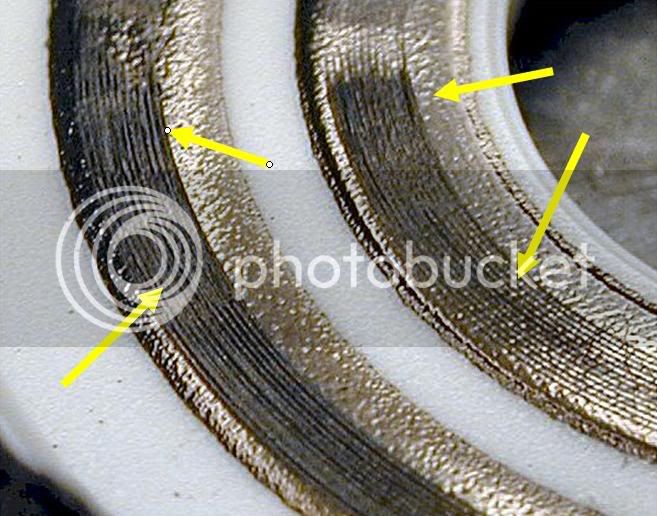

Next --- > Even though the TPS has worked in all previous testing I couldn't rule it out. At this point I had a faint recollection that the problem suddenly became worse after taking all the play out of the throttle cable. Hmmm... I pulled the connector, checked voltages, ohmed the unit at ambient temps and cleaned the filthy sensor. All normal. I back-probed the connector, ran wires up to the dash and Velcroed my cheapie DMM to the dash and went for a ride with Good Pillion™ installed (3). Three bars, fan cycled on, 35 mph BUCK, FART, MISFIRE. Whoa baby, did you see what the DMM showed?!?! Next glitch, DMM showed a major TPS drop-out. By this point I note that the drop-outs always occur between .775 and .778 volts. I could ride anyplace around that particular range and had no problems. Deliberate operation in that range caused TPS drop out and the beginnings of Pillion hammering on my helmet to stop doing that. Back in the driveway I checked my light throttle problem at idle and it was plain to see the TPS drop out. As soon as everything cooled a bit the TPS worked normally again.

911 -- Hello University Motors -- Gary please --

The TPS is held on by two screws, one screw hole is round and the other is slotted to allow TPS adjustment. Refer to the FSM for the procedure. The screws are vertically aligned -- one above the other. Issue 1, why did Yamaha have use security torques screws here? Issue 2, the lower screw access is mostly blocked by the frame. There is ~1/2 inch of space for the torques bit. It's looking like either the intake comes off or the engine comes out to access the screw. First I will try some tool fabrication, I think I can get the little bugger out. [edited 7/26: Both screw holes are oval, both screws have to be loose to adjust the TPS.]

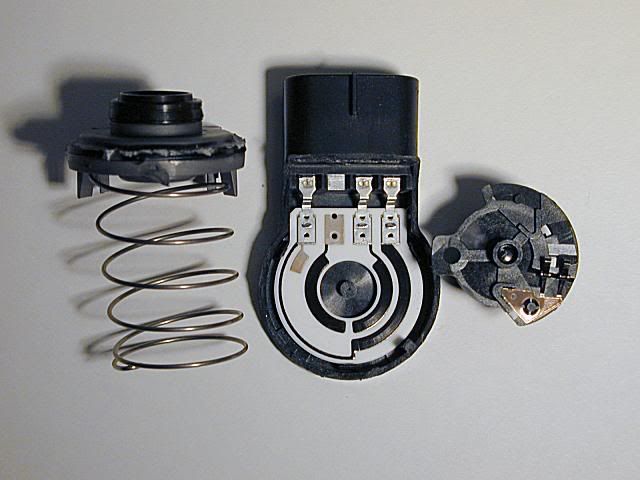

(1) Should anyone consider dissembling the gas cap assembly farther, be aware that there are 4 small springs and a check ball that are fabricated with AllaKhazam's fourth dimensional vanishing capabilities. If you take out the three screws that hold the lock assembly in place take great care not to let AllaKhazam disappear your parts.

(2) Intake manifold pressure runs around 12 inches/Hg. At WOT it drops to ~2 inches. This test also made my FJR run different due to more vacuum volume and a bit of 'shock absorber' effect from the diaphragm of the vacuum gauge. My particular FJR has always taken 3-4 spins of the crank before it fired up. With the hose/gauge connected it fired instantly! Also, it had much smoother throttle response. I will spend some more time looking into this after everything else is sorted out. This shows some potential....

(3) It was gosh darn educational watching the TPS while riding. Idle was .620 volts. I tend to cruise at .770 to .790 volts almost all the time which is most likely why the TPS is worn out in that range. I discovered that I actually move the throttle quite a lot but the amount is so small that I don't notice my hand physically doing it. To avoid the death zone at .775 volts I rode in a higher gear than I normally would. I noticed that at 35 mph in a lower gear the TPS read .720 volts but at the same speed in a high gear the TPS read .850 to 1.100 volts. This means that the engine was over geared and it took much more throttle to maintain speed. Said another way, fuel economy sucks when doing that!