BwanaDik

Well-known member

Pictures of the new stuff?

Coming soon...Pictures of the new stuff?

I've been hearing about these FJR "group rides" for awhile now. Thanks for the advance warning.I really miss the long aluminum bars, Dwayne, as I was really looking forward to see how you might incorporate them on the next group ride.

Not followin gyou. Do you intend to use the magnets with my version?So here is a question, for those how have existing tank bags that use magnets, any chance of a version that is just a small plate to which a bag can be attached without placing it directly on the tank?

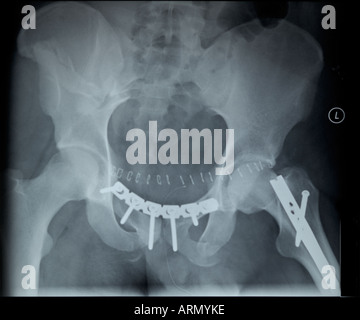

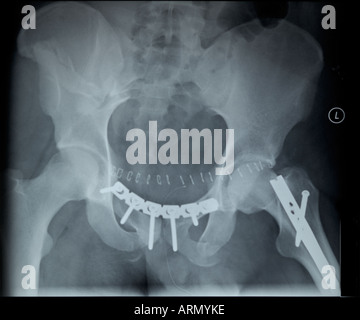

...ummm...not something that was part of the original design plan. Storage was the goal...and protection...and water resistance. To be fair, in order to accomodate this type of request/requirement, the project would be scrapped. The fact is the end result would simply be too little storage space to warrant the effort.So will the rider end be tapered to reduce the risk of "open book" fractures of the pelvis?

Well, thanks Fred! It's been an under-the-radar pet project for a couple years now. A little time here, a little there, etc.Wow!!

This is the first I have seen of this thread. Color me impressed!!

I can really appreciate the potential of having a hard, lockable, weather tight, tank locker. Keep up the good work. I'll be very interested to see the final product.

edit - One question would be: What would you expect to do with the locker when refueling? It would be nice to have someplace to hang the thing without risking scratching the tank. Maybe if it were somehow hinged to flip up for fill-ups? I know that this is probably beyond the scope of your project.

Juggle my dear Fred...juggle! All kidding aside, I'd set it on my seat, like I do my current soft-sided version. It's twists off and on, so is super quick to remove and install right now. When/if I can figure out a locking set up, that may change the time involved somewhat...What would you expect to do with the locker when refueling?

My original foam mock up actually had a location for a D-ring to be bolted to the unit, opening up the possibility of attaching a carabiner clip to say...hang the locker from a brake lever or available RAM mount ball, etc. I haven't progressed to that stage yet because:It would be nice to have someplace to hang the thing without risking scratching the tank.

Love the hinging idea...and yeah, beyond the scope currently. mostly, this has to do with sourcing the tank ring mounts. My first source can't produce them any more at a reasonable price point (his current price was over $100/ring mount, so he stopped producing them). My second source (my plastics company) quoted me $56/mount, so price forced them aside, too. I contacted SW Motech to ask about buying their ring mount bases so I could build my own upper mount to fit their base...and they said "Due to patent reasons, we cannot sell the bases individually. You want a base, you have to buy the tank-bag to match it." After I stopped laughing, I put them on the "useless" pile, too. After a bit more searching, I found the current mounts for $15 each. Cheap-ish, easy and readily available in a variety of tank ring configurations - sold!Maybe if it were somehow hinged to flip up for fill-ups? I know that this is probably beyond the scope of your project.

*sigh*...I suppose it was always bound to be this way... but I'll take yer scraps and be grateful for them...Duane, I have some material from my sound-deading project on the Honda Element. It's from Raamat, and it's a roll of mass-loaded vinyl called "Ensolite" with an adhesive backing; you cut it to fit. It has a soft texture, and might work in the interior of your locker to spruce it up. You just cut to fit, then remove the backing and press into place.

Plus you get the built in benefit that your locker will be acoustically perfect, cause I know that was keeping you up at night.

I'll save up my scraps if you are interested.

Enter your email address to join: