@rjen

Well-known member

This weekend our dutch FJR Community had an organized 'tech day' at a dutch Suspension specialist: HK Suspension.

I used this opportunity to replace my rear shock (Ohlins YA-053) and front springs.

Since mine was the first 2013 they got into the shop it was quite interesting to find out what the new springs look like. Here some answers.

To start:

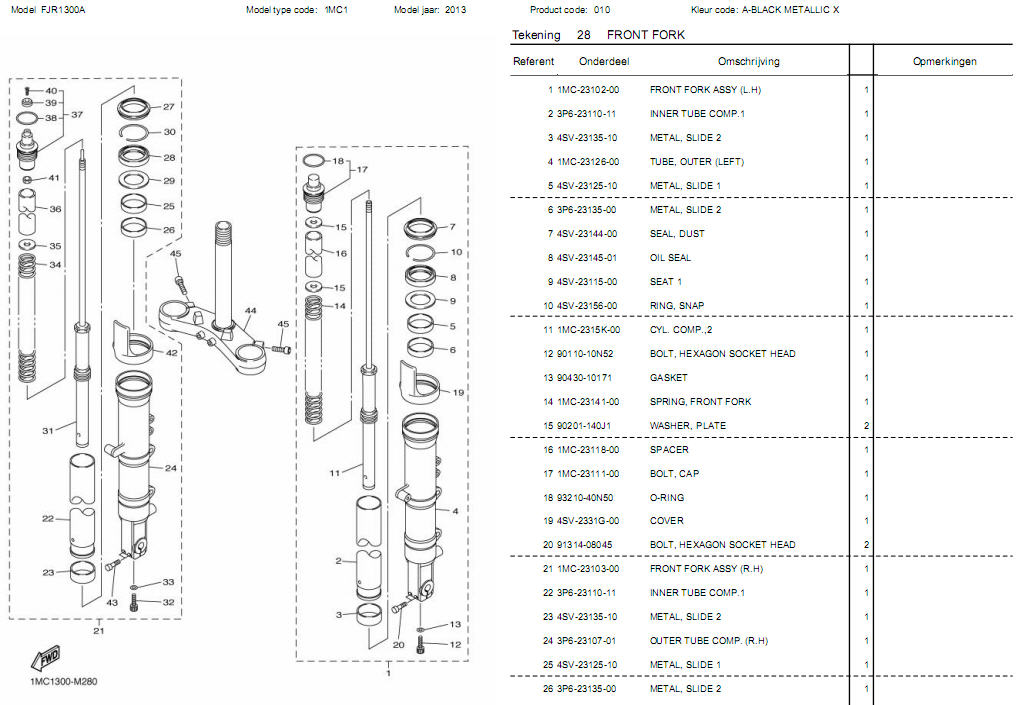

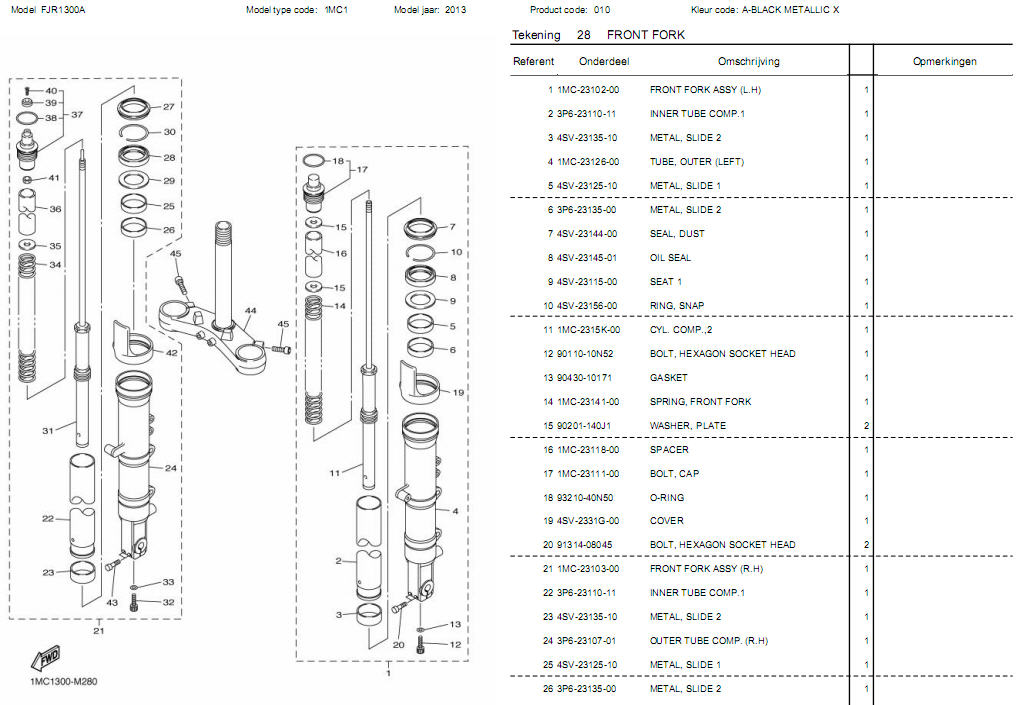

the 2013 model is the first FJR where the front legs are not identical: preload is adjustable on both legs, Damping can only be adjusted on the right leg.

As a result the interior of both legs is slightly different as well...

The disassembly in pictures:

Right leg: on the outside not much difference from older models

First sight of the spring. First observation: the 'filler tube' on top of the spring is shorter than it use to be.

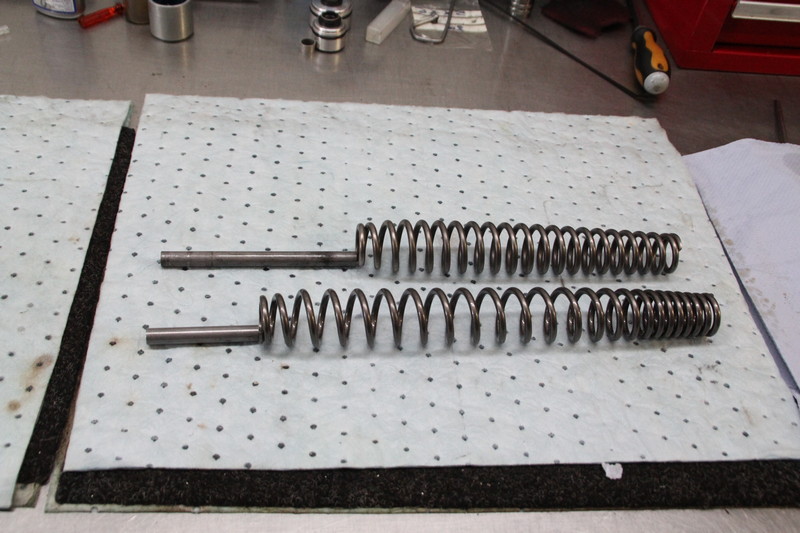

The spring, no surprise yet:

And there it is... it's progressive!

Minimizing weight by Yamaha: the insides are indeed made of aluminium...

Another observation: the needle is now 'loose' in the tube. Got to be careful not to lose it or put it back in upside down...

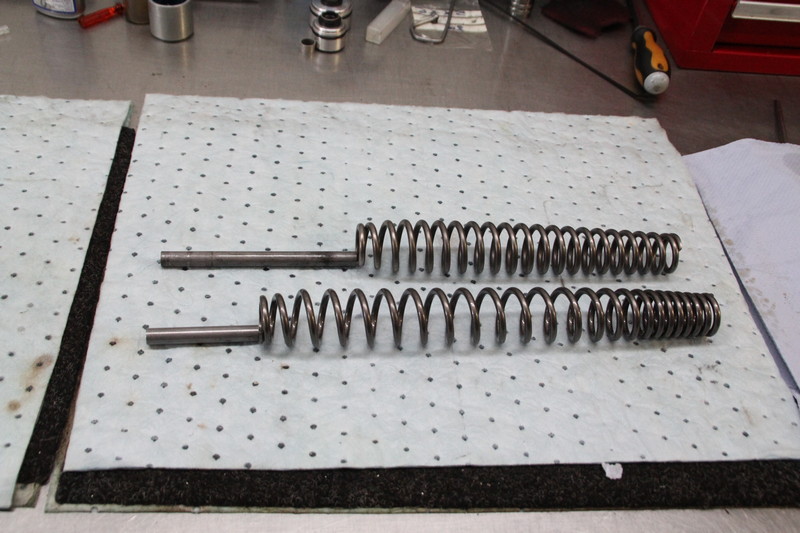

Spring comparison: behind a Gen2 spring with filler tube, upfront the taller Gen3 spring. As it turns out the total length has remained the same.

Measuring the spring strength: this turns out to be unchanged.

Now the left leg: the filler tube here is completely different:

At this point we established that is is possible to use a Gen2 aftermarket spring in the Gen3. We have installed a set of Wilbers springs. Since these are effectively the length of the Gen2 Yamaha springs we have used the old Gen2 filler tube on the right leg, and created a new tube (aluminium) with the same length for the left leg.

The new tube in comaparison to the Yamaha Gen3 tube:

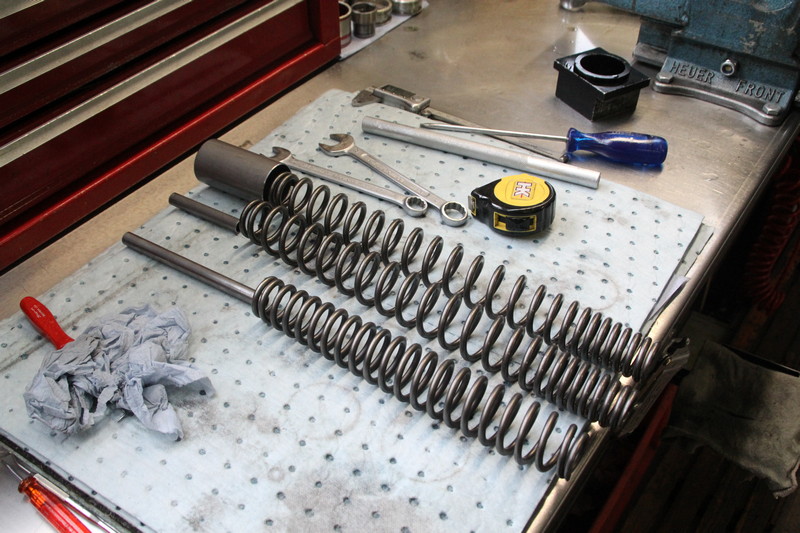

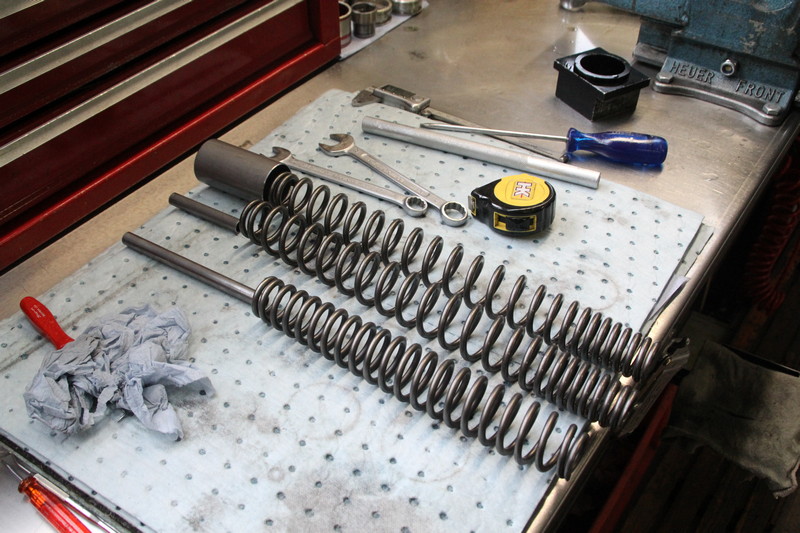

In overview from left to right:

1. A Gen2 spring with the old -taller- filler tube

2. The longer Gen3 right leg spring with original filler tube

3. The longer Gen3 left leg spring with original filler tube

Assembly was a piece of cake.

Some notes from the suspension specialist:

Results:

I rode about 300km since including highway and twisties: the Gen3 feels great. Lot of precision, very predictable both in long and short corners, a littje less comfortable than the factory settings but well worth it in improved sports riding...

I used this opportunity to replace my rear shock (Ohlins YA-053) and front springs.

Since mine was the first 2013 they got into the shop it was quite interesting to find out what the new springs look like. Here some answers.

To start:

the 2013 model is the first FJR where the front legs are not identical: preload is adjustable on both legs, Damping can only be adjusted on the right leg.

As a result the interior of both legs is slightly different as well...

The disassembly in pictures:

Right leg: on the outside not much difference from older models

First sight of the spring. First observation: the 'filler tube' on top of the spring is shorter than it use to be.

The spring, no surprise yet:

And there it is... it's progressive!

Minimizing weight by Yamaha: the insides are indeed made of aluminium...

Another observation: the needle is now 'loose' in the tube. Got to be careful not to lose it or put it back in upside down...

Spring comparison: behind a Gen2 spring with filler tube, upfront the taller Gen3 spring. As it turns out the total length has remained the same.

Measuring the spring strength: this turns out to be unchanged.

Now the left leg: the filler tube here is completely different:

At this point we established that is is possible to use a Gen2 aftermarket spring in the Gen3. We have installed a set of Wilbers springs. Since these are effectively the length of the Gen2 Yamaha springs we have used the old Gen2 filler tube on the right leg, and created a new tube (aluminium) with the same length for the left leg.

The new tube in comaparison to the Yamaha Gen3 tube:

In overview from left to right:

1. A Gen2 spring with the old -taller- filler tube

2. The longer Gen3 right leg spring with original filler tube

3. The longer Gen3 left leg spring with original filler tube

Assembly was a piece of cake.

Some notes from the suspension specialist:

- Damping of the Gen3 was judged to be fairly soft. To improve this a different grade of fork oil was used after replacement (grade 10)

- Air chambers in the legs were of different size (10 cm right side, 12 cm left side). We found no explanation for this. After replacement both were set to 10 cm.

- Settings with the new springs in: rebound unchanged (3 rings), 10 clicks damping topside, 8 clicks damping bottomside.

Results:

I rode about 300km since including highway and twisties: the Gen3 feels great. Lot of precision, very predictable both in long and short corners, a littje less comfortable than the factory settings but well worth it in improved sports riding...