The following is not intended to be an install guide, it is just an overview of

project management.

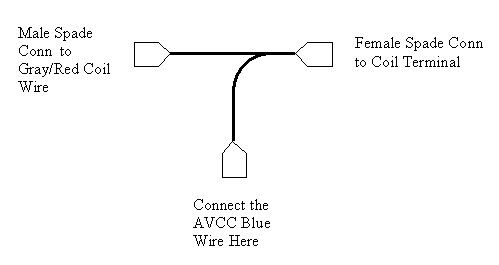

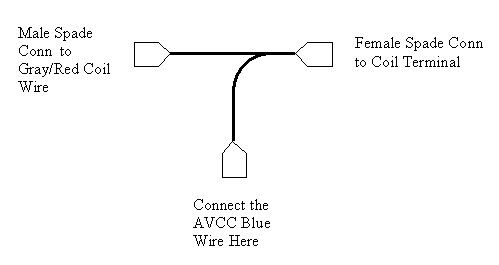

On a big project like the Cruise Control, break the install into sections. I set up a 6' long folding table and lay out all the parts as they will be installed on the bike so I get an idea of how it will need to be routed and mounted. I will also use this to help layout any wiring, fuses, connectors and switches that I may need to add to the install. This helps me understand what connectors and wiring bits I will need to buy or fabricate. The following drawing is a little "Y" using spade connectors that I made in advance to attach the CC harness to the coil without cutting or splicing wires (get the connector's sex correct!):

Start with the key items. First drill the throttle tab, this must be successfully done or there is no point in going on. Now attach the bead chain to the tab and get the hardware positioned with clearance then tie a string to the bead chain and tie the other end to something so you can pull up the chain once ready to connect it to the servo cable. This gets one of the more aggravating things out of the way early. Now you can see where other things go, like brackets. Bend, fold, drill and twist any metal that will be used and paint it so you won't have to interrupt the assembly. The metal strap that holds my CC on the swing arm was prefabricated and painted. Seal up the control pad and sort out the mounting for the control pad so it is ready to go.

Look at all the harness wires, loose wires and the servo cable and figure out where they need to run and what holes and openings they will snake through on the frame and around the engine. Now you will be able to see what you need to take off the bike to route the wires and vacuum line. Look at your wire routing and see if the wires need some form of loom or armor, install as much as you can on the bench before installing on the bike. Note the corrugated armor I used on my servo wires because it runs past hot and moving items.

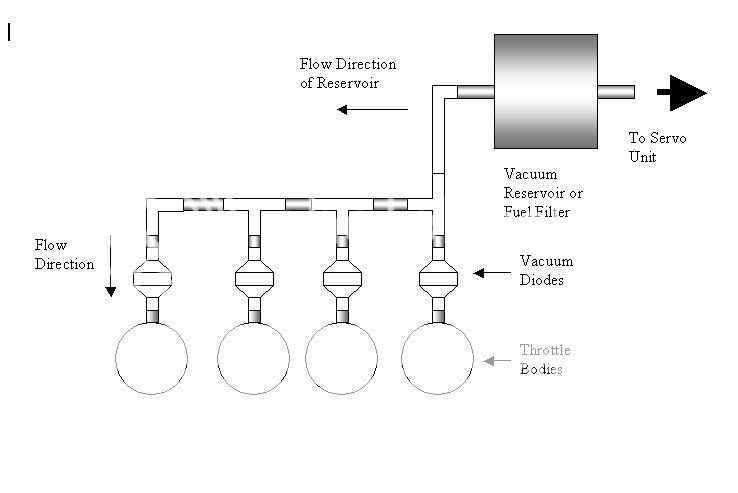

Plan out how you are going to manage the vacuum at the intake manifold. This will help you put together a shopping list and prefabricate parts. The generic drawing I made will let you see how many connectors and Tees you may need as well as the vacuum diodes (check valves) and reservoir. I chose to tap all four throttle bodies, others have tapped fewer. Pay attention to the check valves flow direction! This setup has 3 Tees and 1 90º elbow. I see I forgot to shade the rubber hose that runs to the reservoir. Oops! I used a '85 Gold Wing gas filter as my reservoir.

This isn't a race, leave time to get it done. The control pad will take time to dry after sealing, paint will take time to dry. One of the hardest things I have learned about doing this kind of project is

when to take a break or walk away and come back later with a better attitude or rested body. Once you are tired or frustrated things start to go wrong and it only gets worse from there if you continue. This is why I usually tell people that a CC install isn't a good tech DAY project. If you install a

lot of these kits like Smitty did they can be done in ~4 hrs but if you are doing it for the first time leave your self time to do the work and break time to walk away.

Good luck!