GPRIDER

Well-known member

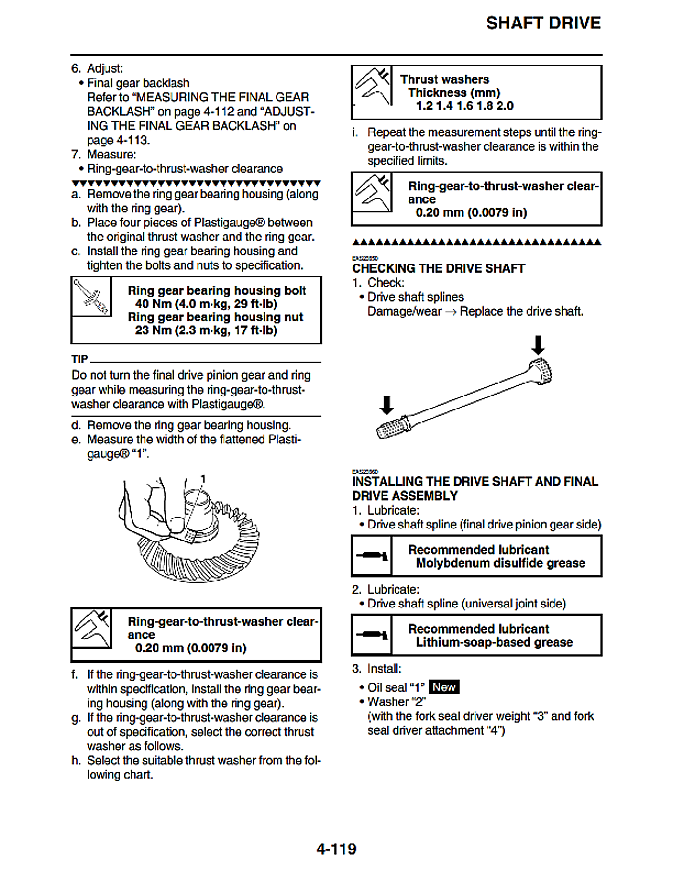

I had a Yamaha Venture before getting into FJRs. This was before I knew about much maintenance. My Venture never had any splines greased and at 60,000+ miles it sheared the splines after they had rusted and corroded to a very bad stage. I did a lot of riding in the rain so I'm sure that contributed to the demise of the splines. They need to be lubed at least once in my opinion to help keep the rust away.

GP

GP