Alright! Things slowed down a bit this weekend. Some other house stuff and out side of house stuff needed attention.

I do have pics to post on the current progress which will most likely get posted tomorrow.

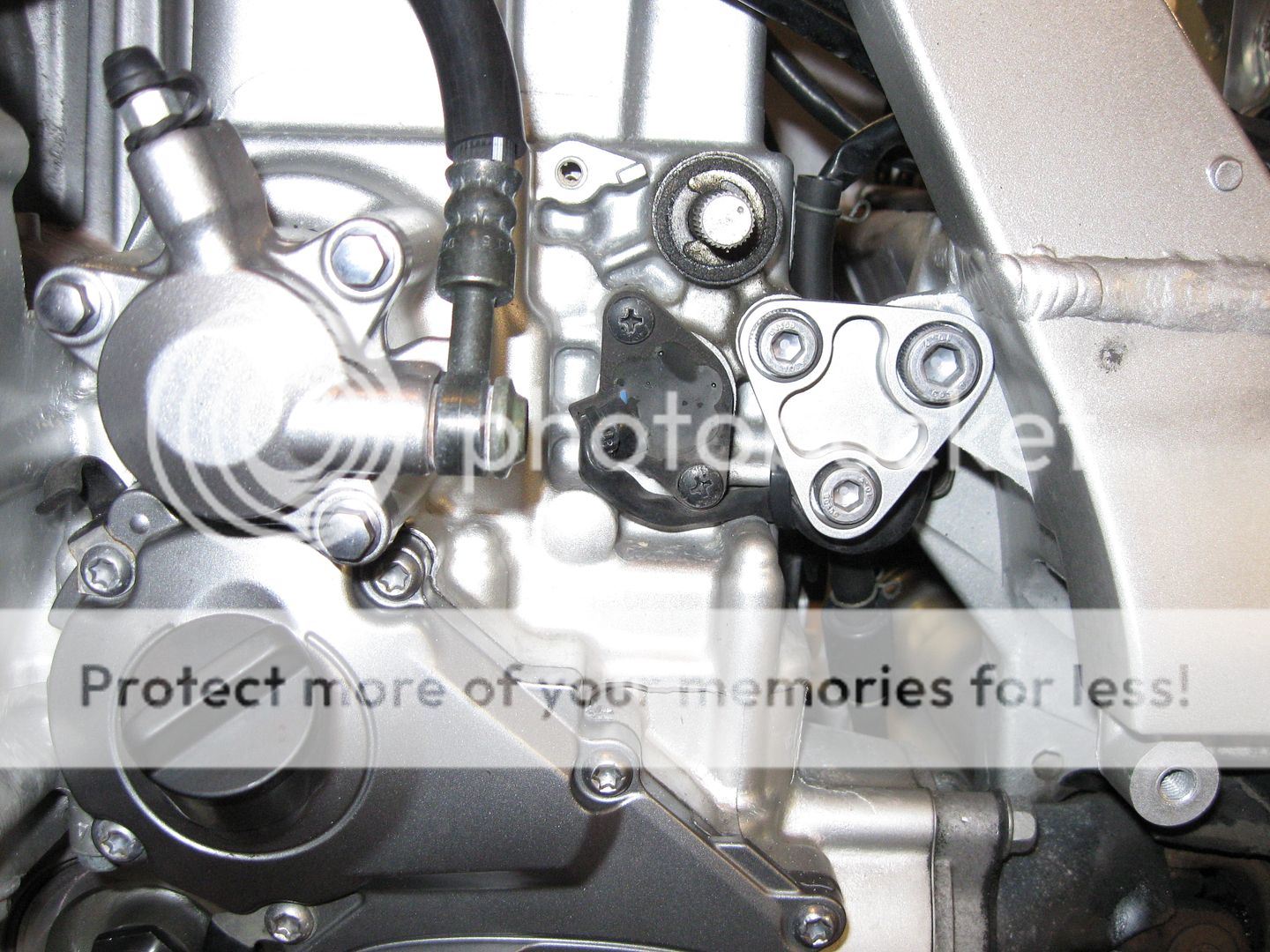

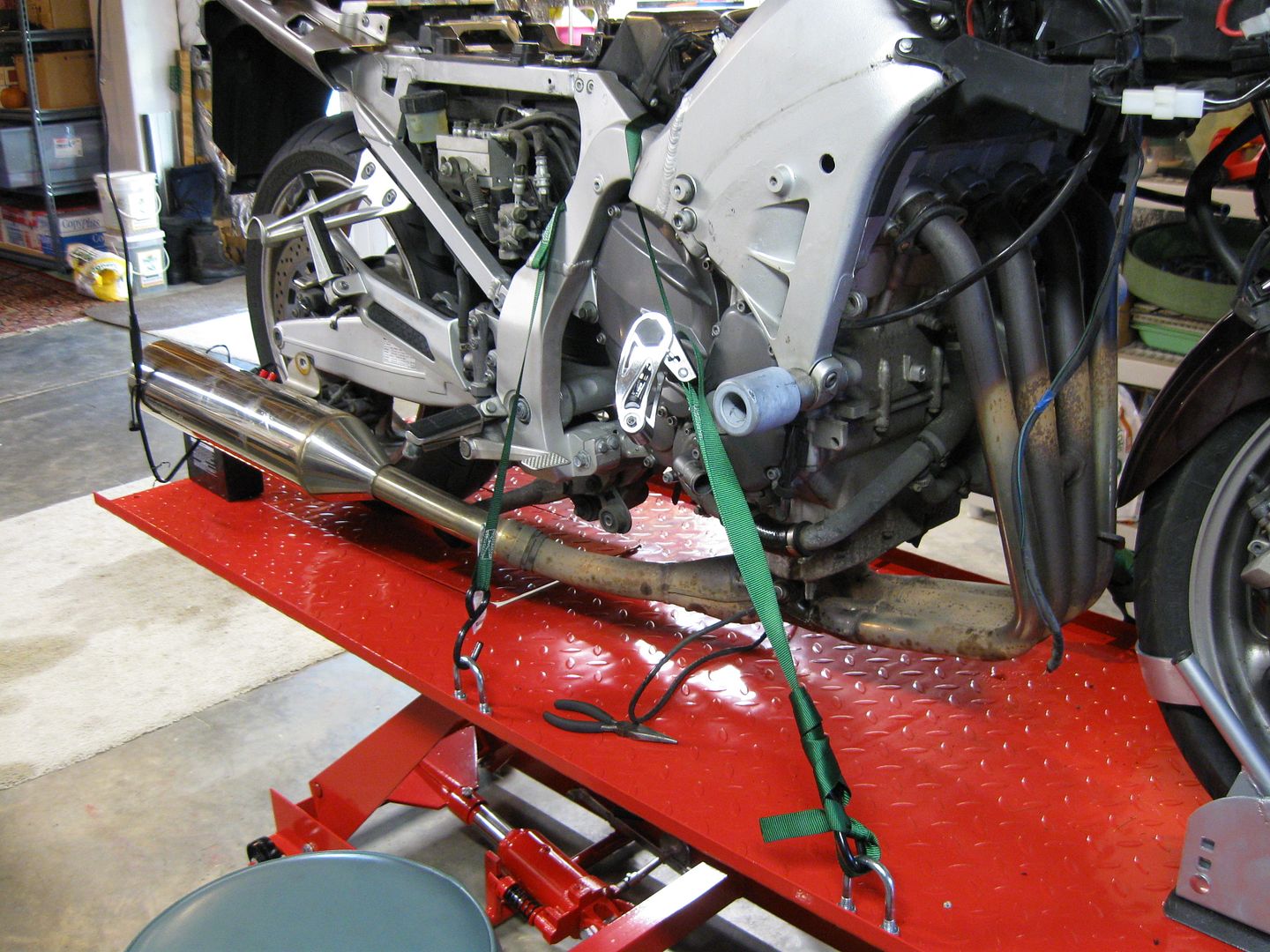

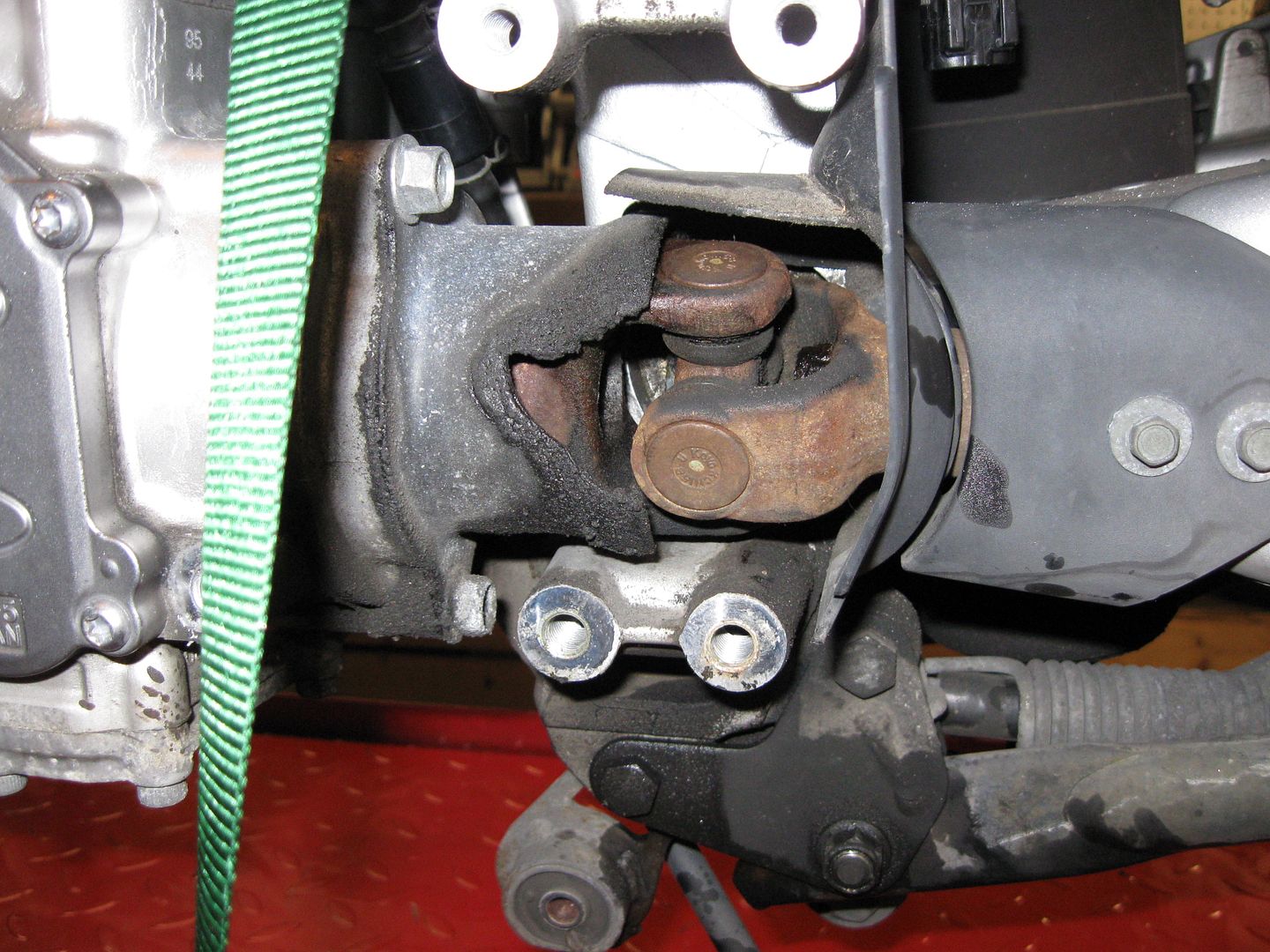

I have a question though which puzzles me. Here's a pic of my CURRENT 2007 engine coming out:

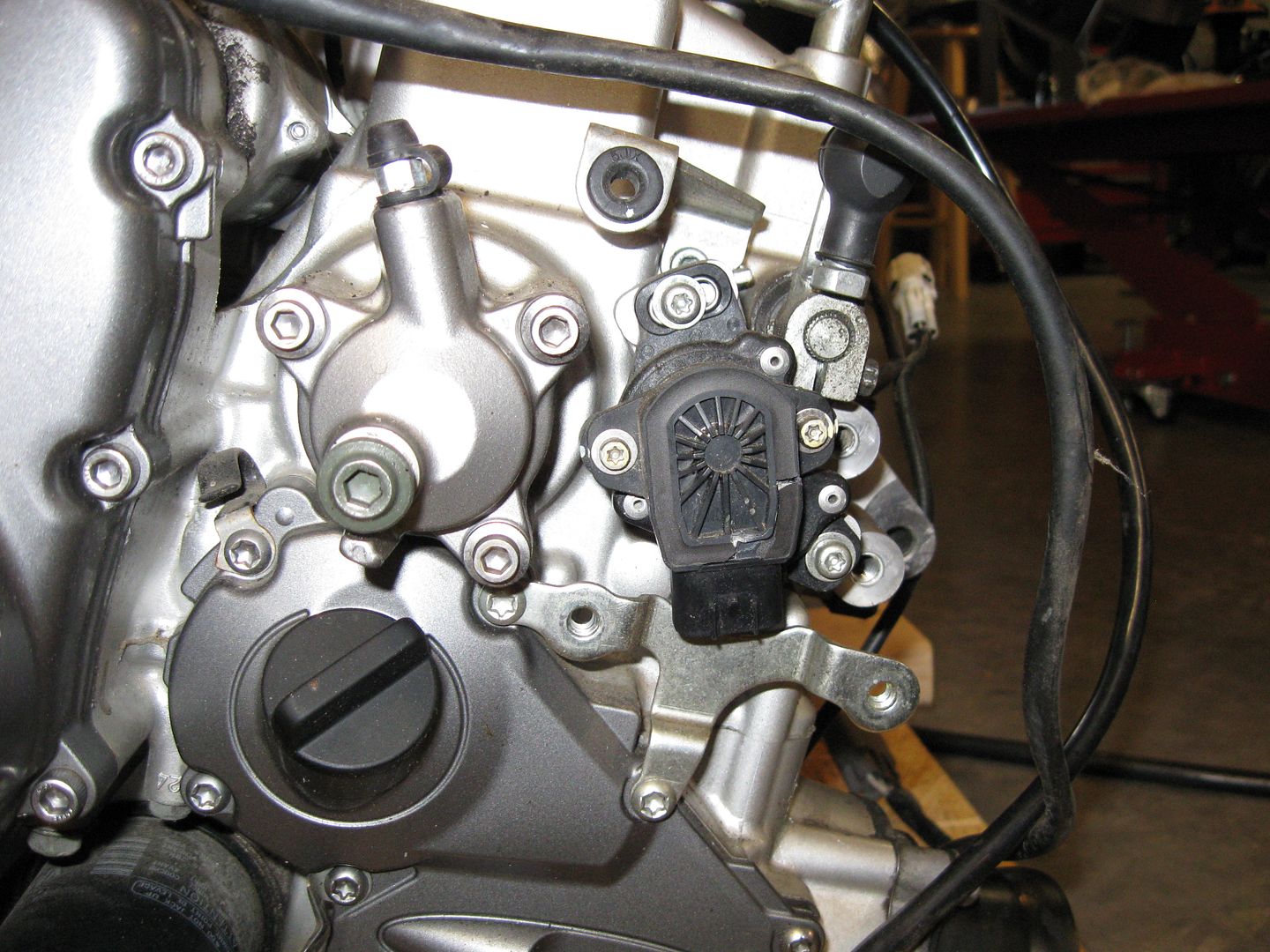

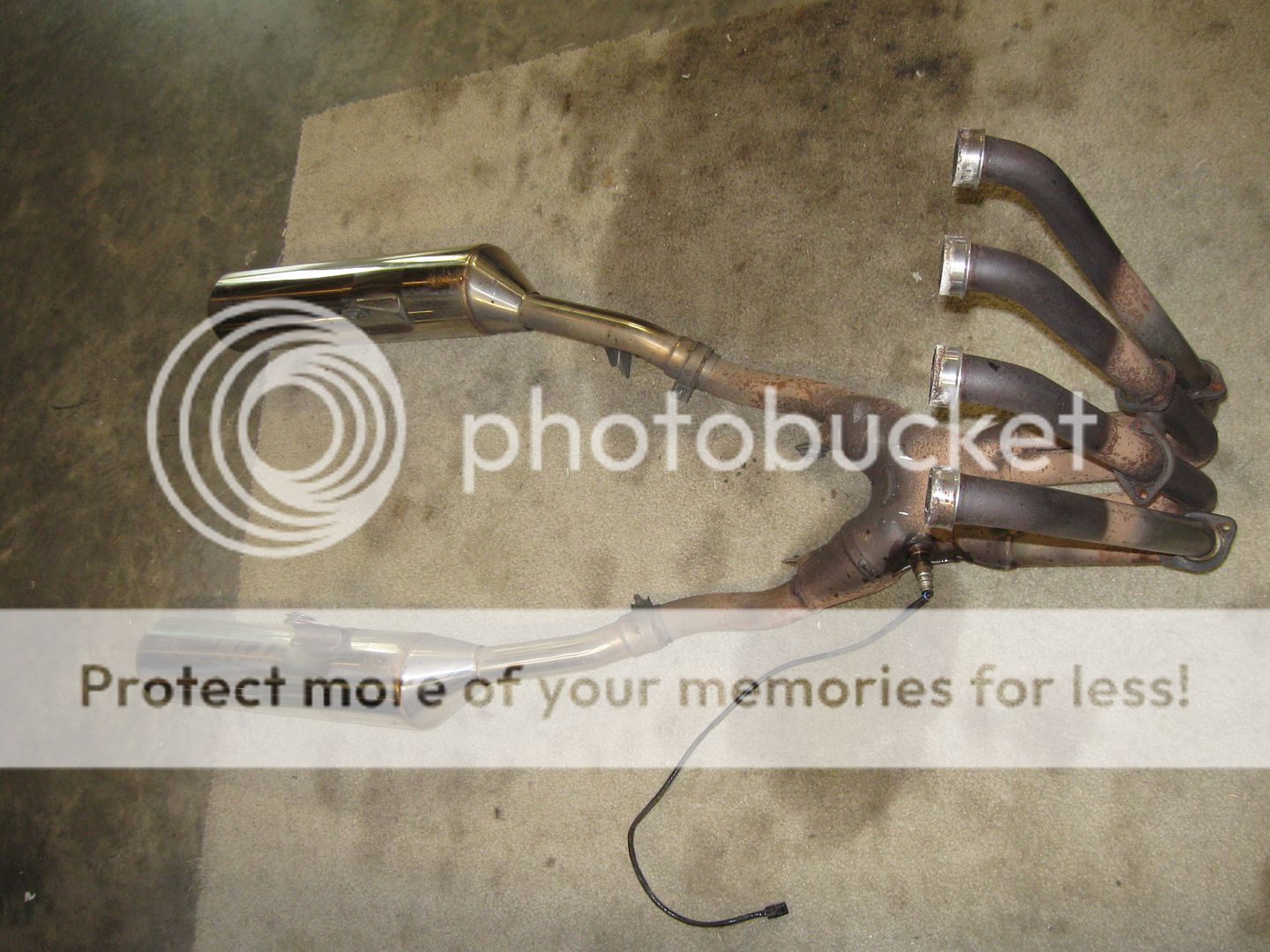

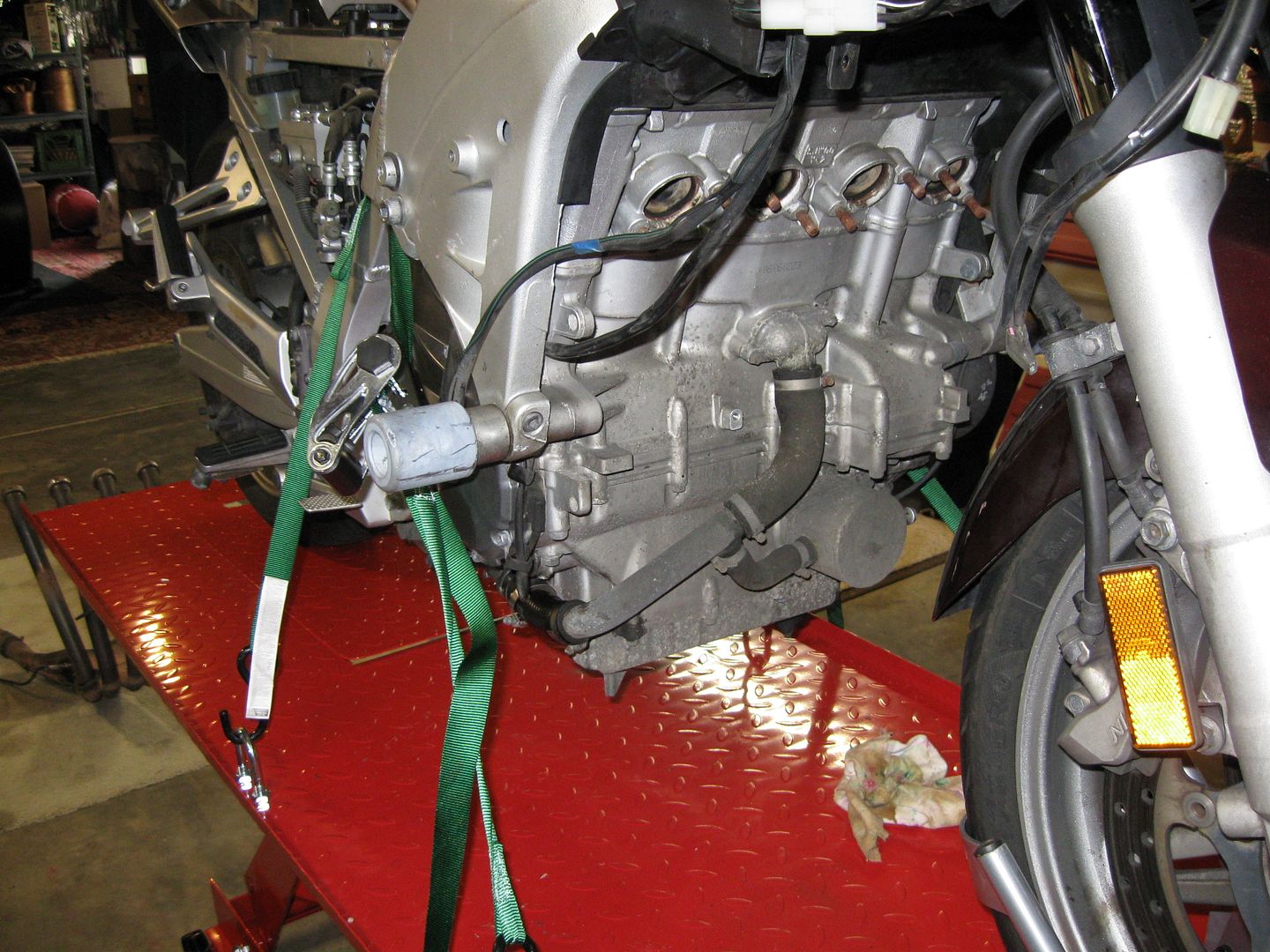

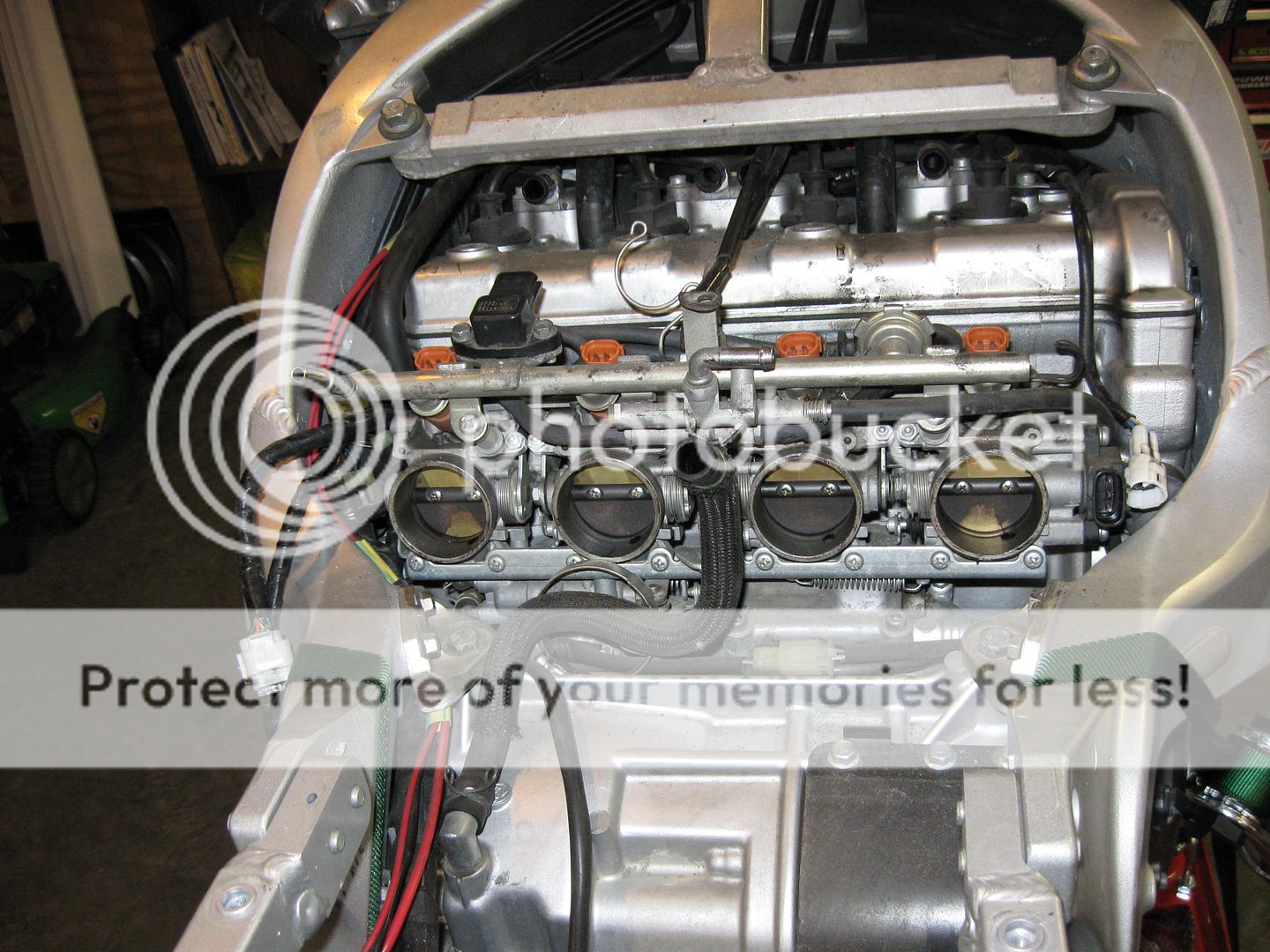

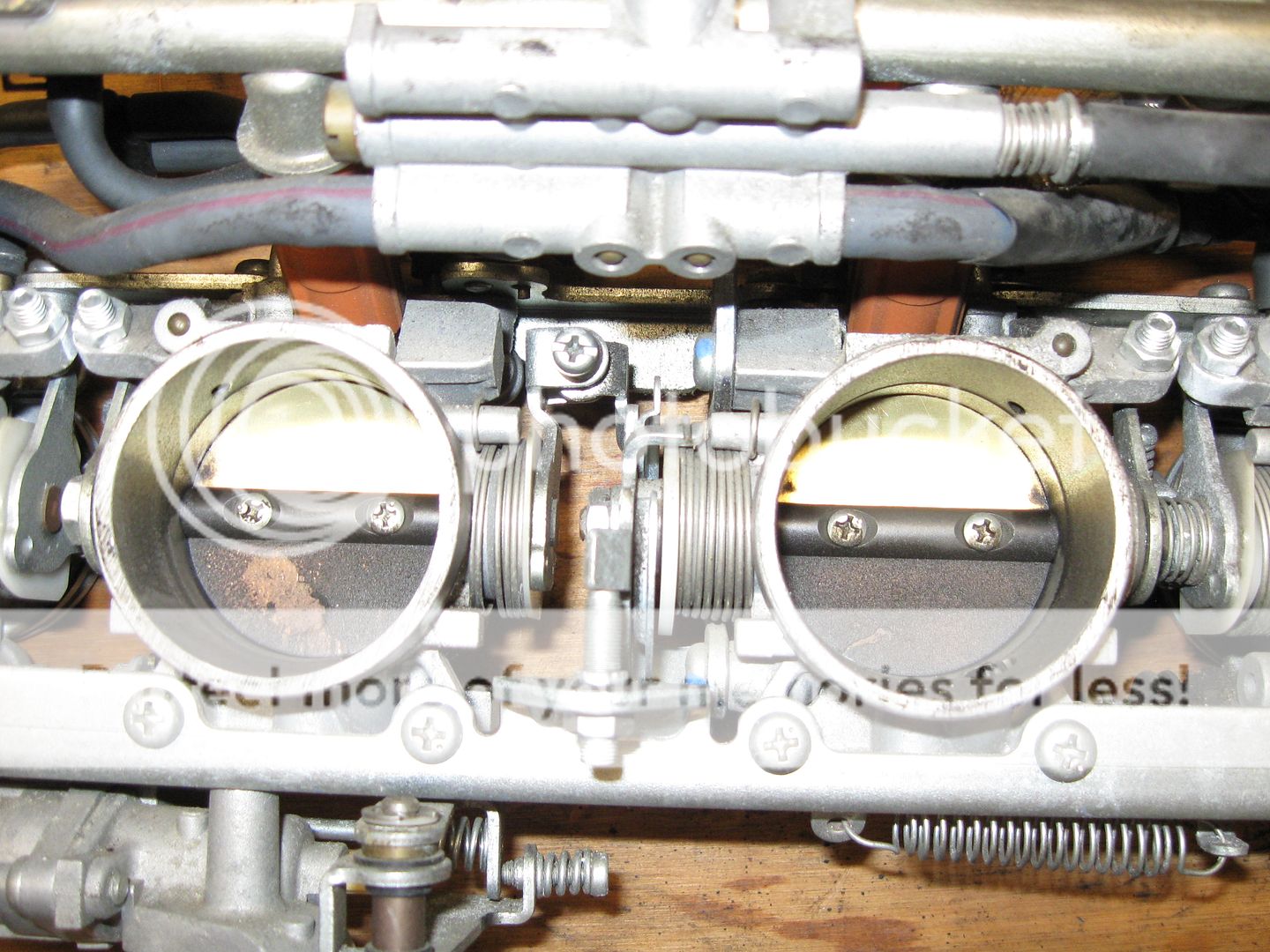

And here's a pic of the "new" engine to be installed:

I'd like some assistance identifying what "Gen/Version" of clutch slave cylinder is on the replacement AND the stuff next to it - Black connector etc.

I'm hoping I can just move what I have to the replacement, but IF this engine is from another year.... I'd like to ID just what year that is! Everything else SEEMS like it's the same as far as I can tell.

Thoughts? (and thanks!)

Ok, seeing as you have an AE engine, which in order to make work properly with your bike, you'd have to split the motor and change the shift barrel and associated hardware out, that leaves you with a few options.

Option 1: Sell the AE motor and split the motor with the bad transmission to start replacing parts. I believe that's your best bet, more on that in a bit.

Option 2: Split both motors and swap out the shift barrel & associated hardware plus all of the other bad parts associated with your broken trans motor. This leaves you with a spare engine, and some used transmission gears/forks/whatever to fix your broken engine. If you're going to go this route, I'd be interested to see how the gear dogs and pockets look on an AE auto shift motor with (how many?) miles, so take pictures please! This also gives you an additional 16 valve shims to work with should you want to re-shim, and you'll also have a bunch of parts handy for replacement of anything that more than likely won't go wrong with your original 60,000 mile motor.

Option 3: Sell the AE motor and buy an A motor, preferably '08 or later (updated trans). Probably the easiest route but seriously not much easier.

With all three options, you'd still want to make sure you end up with a newer 'blue dot' cam chain tensioner.

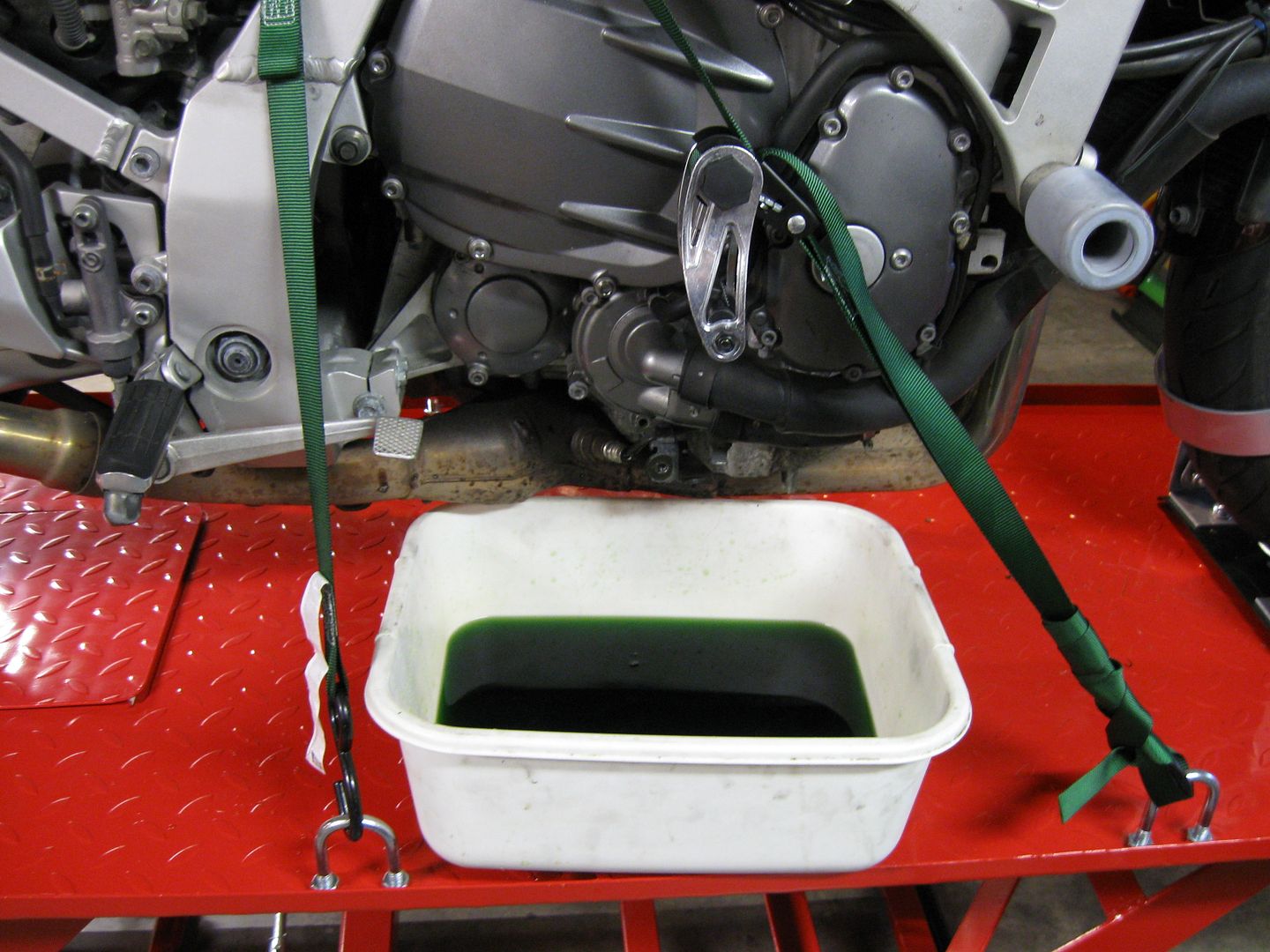

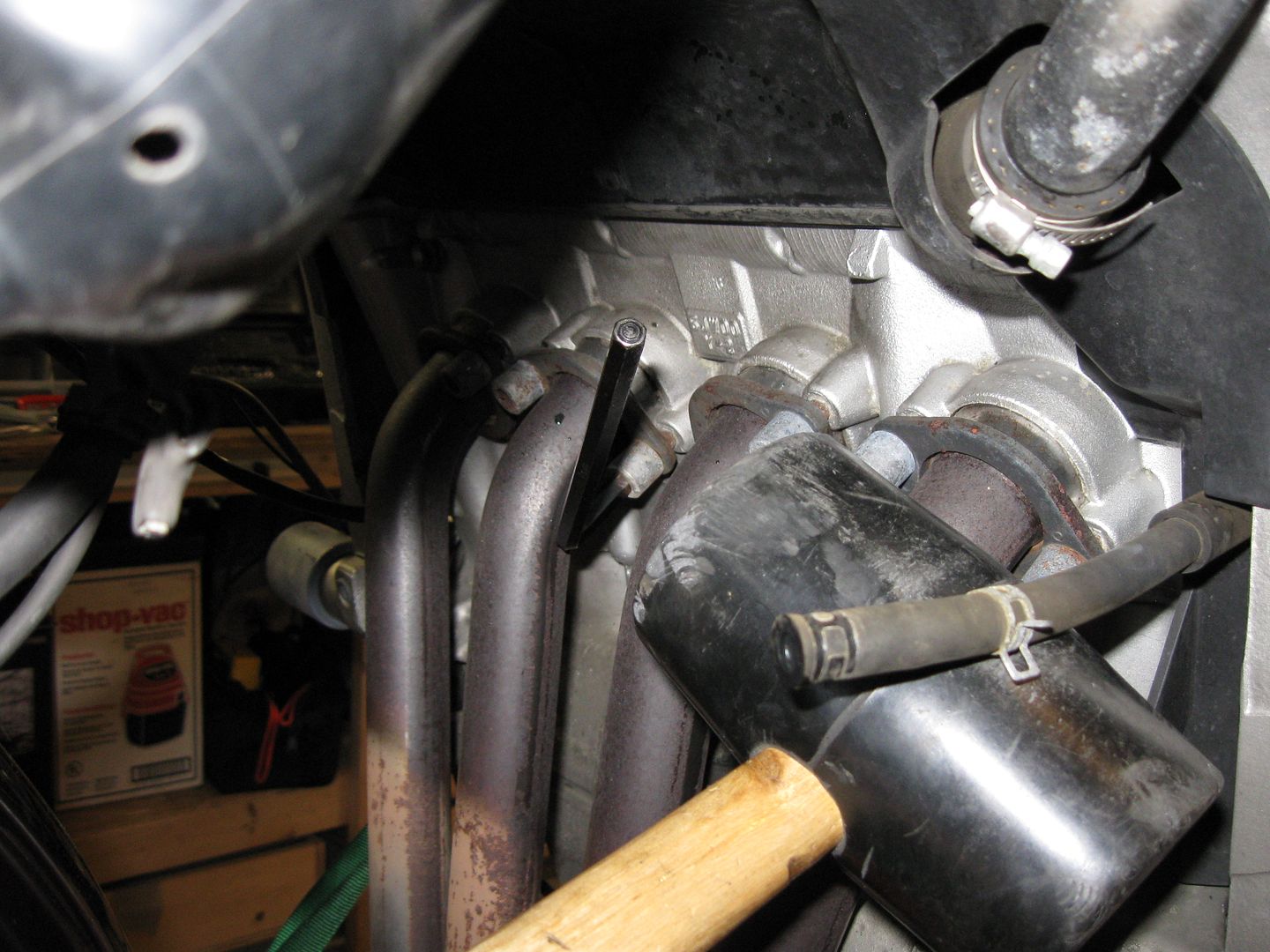

I've had my motor out of my '06 bike to fix the "popping out of 2nd gear" issue that's common with many big displacement high torque bikes, and unfortunately I'll probably be doing it again this winter to fix the same issue. This other transmission issue your new bike has is kind of an anomaly; most people have the issue I had, I don't remember reading about any other transmission failures with any year FJR. I do have to tell you the biggest bitch is getting the motor out of the bike, and you're already half way there apparently.

Dis-assembly of this motor is not rocket science at all, it's fairly straightforward. If you decide to go this route, myself and a slew of others on the forum could talk you through it if you run into any difficulties. Along with whatever broken trans parts you're replacing, remember to buy new gaskets, coolant tube o-rings, and the 10 main bearing bolts which according to the service manual are one use only. Pick up a service manual if you haven't already. Or get a .pdf copy of one online from...somewhere, it's out there. Or both. That's still the cheapest route, IMHO. Either way, I'd start with splitting the bad trans motor and finding out what you can about what is broken. You might even get lucky and find a newer trans for sale; I scored one for cheap from a forum member when I did mine.

You can go to the Yamaha OEM parts supplier website of your choice and compare part numbers between the A and AE bikes (I use Yamaha Sports Plaza). From what I can tell the only difference to the motor internally is the shift barrel and its hardware, which unfortunately means you're still in for splitting the motor. If you decide to split the bad trans motor, please take pictures and document, that kind of information is definitely appreciated here, and it's part of what this forum is all about.

Keep us all posted on which way you decide to go.