turbodave_98

TurboDave_98

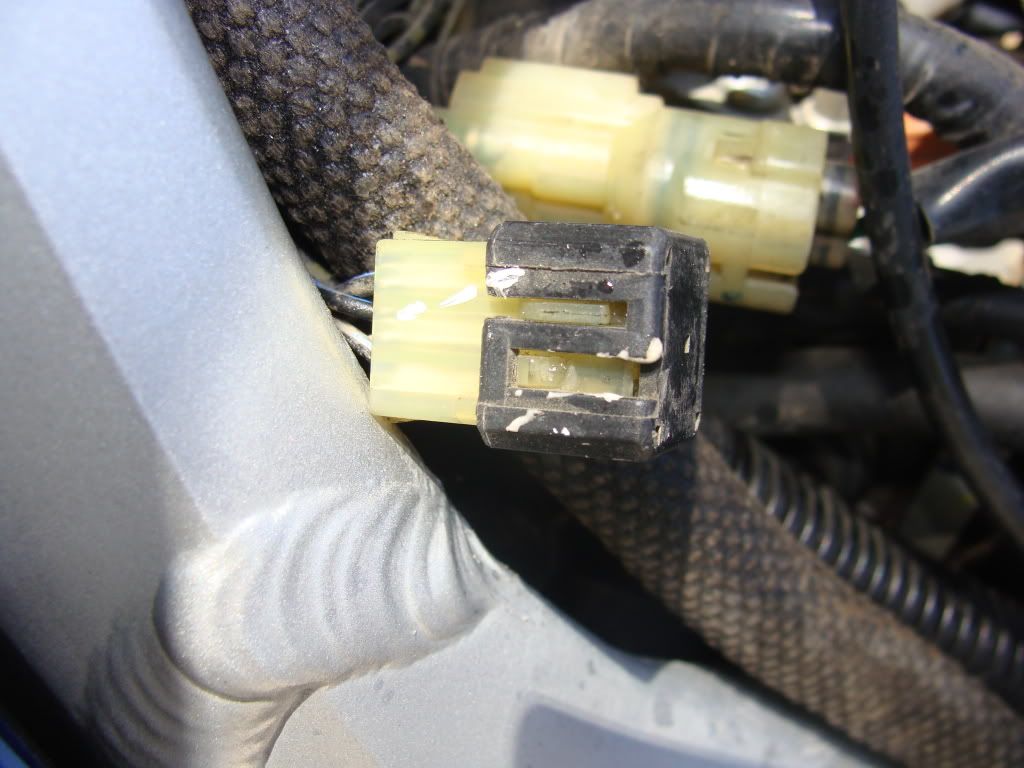

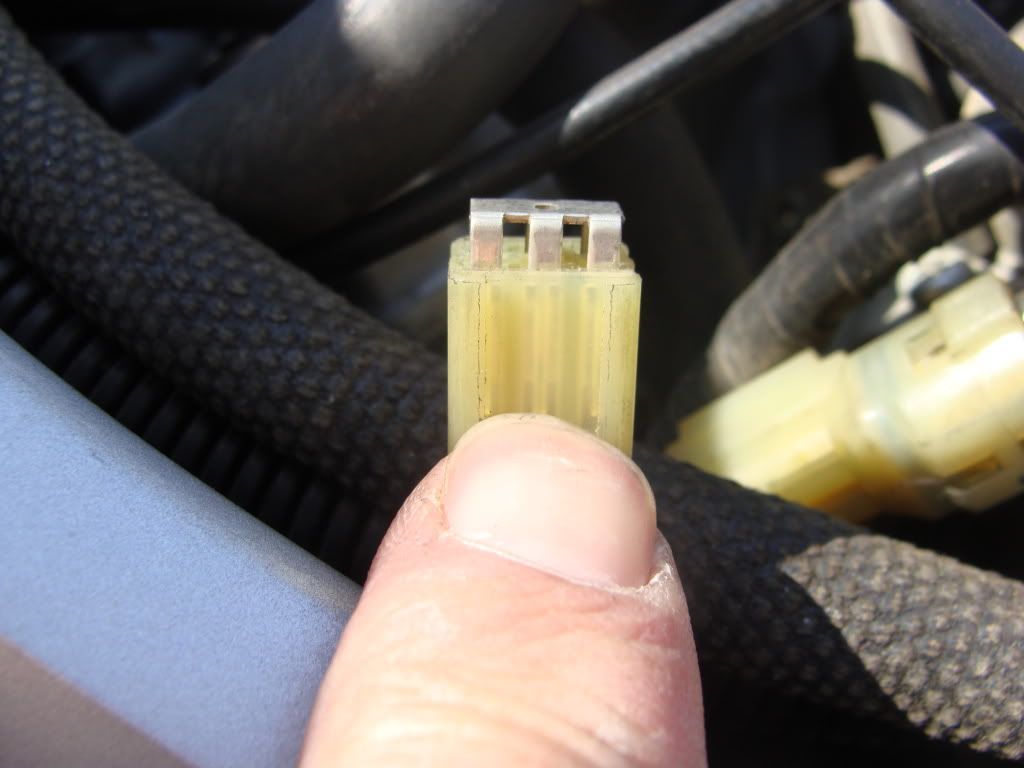

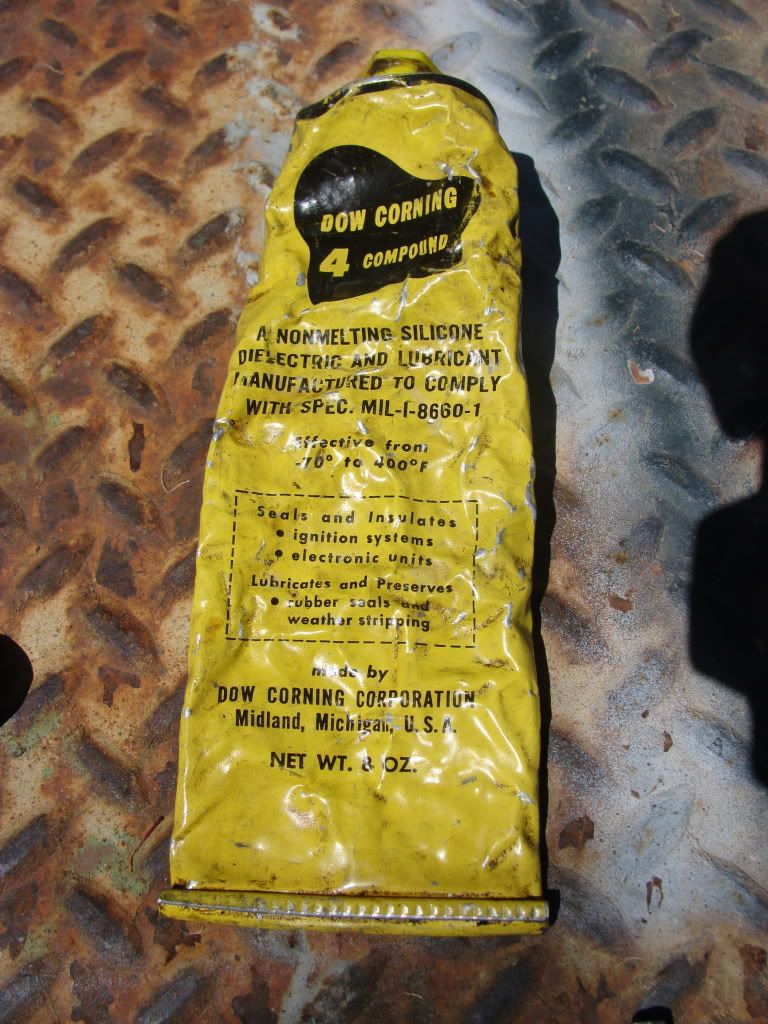

Update 23 April 2009OK, good advice Dan. Assuming that the plug ground wire is intact and makes good contact to the frame somewhere, and the individual wire ends and loop wire connecting are all ok, then filling the cap w/dielectric grease would weather proof the assembly. Plus tying it down in the windstorm is I agree recommended (I just pushed mine up between the frame and wire bundle from the front of the bike for now). Some have apparently had overheating issues, I presume from high contact resistance and/or a poor ground somewhere. There are at least two more of these dudes back under the left seat frame.Having not seen any of the other incidents of problems with this connector,I can only speak to what I saw. I don't think mine was a heat or current related problem. It was simply a bad piece of mechanical design. Take six small gauge wires with crappy crimped on pins on their ends, stick them all in a comparatively heavy connector/shorting bar/ plasticcover and then leave it all sticking out like a long stemmed flower to flop around in the wind and water. It's a guaranteed invitation to metal fatigue and, then, subsequent intermittant grounding and heat problems. Next time you change plugs or do a TBS, you're right there were you can clean it up, slop on some sealant or dielectric grease and bind it down to the rest of the wiring bundle so it doesn't wave around. Should obviate he problem.

Dan

Someday I may wrap the wire ends with a single strand of copper wire, solder the ends together, and cover the bundle with heat shrink tubing. Fixed forever.

Gary in Fairbanks

You would have to ass-u-me that this situation, like the ignition switch debacle, is limited to 2nd gen bikes. Either the 1st gens don't have these funky ground collectors, or they are different or situated in a different location. I've never heard of anything like this on a 1st gen and there are a bunch of them that have a ton of miles and have been "ridden hard and put away wet", so to speak.

Also, I am not all that certain that "Yamaha" is fully aware of this problem. Just because one of their service centers has seen a few cases and is now savvy doesn't mean that the corporate is "aware" of the issue yet. Those that have experienced the joys of this connector failing or giving these symptoms might want to follow-up with a complaint somehow. While I do not think this problem would warrant a full-on recall like the switches, it would sure be good if all the service guys were notified of the problem so they could look for it during other preventive maintenance.

There is no doubt in my situation that Yamaha HQ in Cypress has been told of my failure on my 06 AE. I was there when the call was made to HQ. Bad news, seems the primary power harness is on backorder(wonder why??) and not available until the second week of May 2009. that puts my bike down for almost one month, bummer.

I have always been a Yamaha owner since the early 70s and I must admit the 3 ignition failures and now the shunt ground debacle is making me wonder what is coming next? I have been fortunate with all my other Yamahas which have include DTs, RDs.XSs, YZs, YZFs, Royal *s, Ventures, Radians, and one 05 FJR. Only had one complete road side failure and that is my 06 AE. Well, it is what it is!! :angry2: