Brodie

Darksider #16 - and Proud of it !

- Joined

- Sep 17, 2006

- Messages

- 1,450

- Reaction score

- 529

oops, duplicate post.

Last edited by a moderator:

Griff

I see a problem with what you are proposing to do. My grounding Harness is designed to take ALL the electrical loads carried by the bike's grounding system and provide an alternate path to battery negative terminal. The largest wire Yamaha uses is the metric equivalent to 16 gage. Every one of my connectors channel the electrical path to an 8 gage butt splice via 16 gage TXL wire. This 16 gage is the largest wire the connector's pins is rated for. The butt splice performs the same task that the 6 tined "spyder" does - it ties together (shorts) all the wires within that connector. From this 8 gage butt splice, I run a 10 gage SXL wire back to the battery negative terminal.

Think of it... Yamaha runs one skinny wire from spider to spider. The last one before Battery neg. is the S4 connector. My Grounding Harness adds to this with a big piece of copper wire - not take the place of it. It takes the power away from the bikes harness at each connector, so it does not allow the build up of resistance at the S4, or S6 spyders.

Also note that the S4 connector is special, it forms a Y in the path. It is fed by S3, and S6 as well as the path to Batt. S3 and S6 are plugged into my Grounding Harness and are channeling power away from S4.

Install the Grounding Harness I sent you. Check the repair work that the mechanic did in Michigan, and let the S4 plug on my harness dangle. There is enough redundancy built in, that you are still fully protected.

If you still feel uncomfortable with this, let me make you a special replacement Male connector to plug into my Grounding Harness S4 and splice into your repair. Just bare in mind, there is no room to work in that spot. You may want to leave that repair alone if it is done well.

By the way, All the wires are crimped. There is only one spot I used solder and that is at the ring terminal at the battery negative terminal. I chose to use it there "just in case" someone has a problem with battery corrosion. I bought a High Dollar "PressMaster" crimping tool rated just for the Sumitomo .090 series pins. The crimps meet Sumitomo's design specifications.

Griff, you paid good money for my product, install it un modified as per the instructions laid out on my personal website. It will not let you down.

Let me know how it turns out.

Brodie

Yep... that's the one.I believe it's opposite the S4. As in right, front, top of engine. It will have Black wire with white stripe .

Art, I'm on the list now, but I sure hope after getting the plastic off, it will be plain to a non electrical person such as myself what plugs where. Are the OEM plugs just left where they rest or what? I viewed the pics, and even though they are good, they don't give me the specifics but figure it will be more clear when I get into the job.

doctorj

Hi SteveHey Brodie,

I've been reading about the spider bite problem and thought I'd give you a shout to see about getting one of your harnesses. Is it just one harness or are there others for grounding the headlights and other high draw items. I've read about two other harnesses besides yours. Is yours the only one necessary or should I see about getting the others as well.

Thanks for you time.

Regards,

Steve

Just as a follow up, I got the harnesses in today and installed. They look like fine products. Even though I had not had any problems, I thought it good to do this prophylactically to have more confidence in the bike i.e. not get stranded somewhere. And I had most of the tupperware off to do other maintenance and coolant flush. Now for the tupperware reinstall :angry: . The tupperware on my two bikes are making me want a naked bike someday :yahoo: . Hmmm, now to get Yamaha to bring that 1200 Super Tenere to the USA, NICE.Doc

Nothing is left just hanging. The lights and fans are unplugged, and the T-harnesses are plugged into each end of what you unplug. So nothing is left unplugged. Then you run the ends of the T-harnesses to the engine and put them under a bolt for a good ground.

Art

Just order a set from Art, and then PM me. It would be like the blind leading the blind :dribble: . Seriously, it isn't too bad at all. I did forget to add dielectric grease but that isn't too bad. I'll do that when the bike hits 100,000 mi. maybe. Since this is not a safety issue (well maybe) and not affecting large #s of bikes, I betcha Mama Yama won't issue a recall/fix, but I've been wrong once or twice in the pastI hope Yamaha issues a fix for this soon cause I lost when it comes to electrical stuff...:|

Just order a set from Art, and then PM me. It would be like the blind leading the blind :dribble: . Seriously, it isn't too bad at all. I did forget to add dielectric grease but that isn't too bad. I'll do that when the bike hits 100,000 mi. maybe. Since this is not a safety issue (well maybe) and not affecting large #s of bikes, I betcha Mama Yama won't issue a recall/fix, but I've been wrong once or twice in the pastI hope Yamaha issues a fix for this soon cause I lost when it comes to electrical stuff...:|.

doctorj

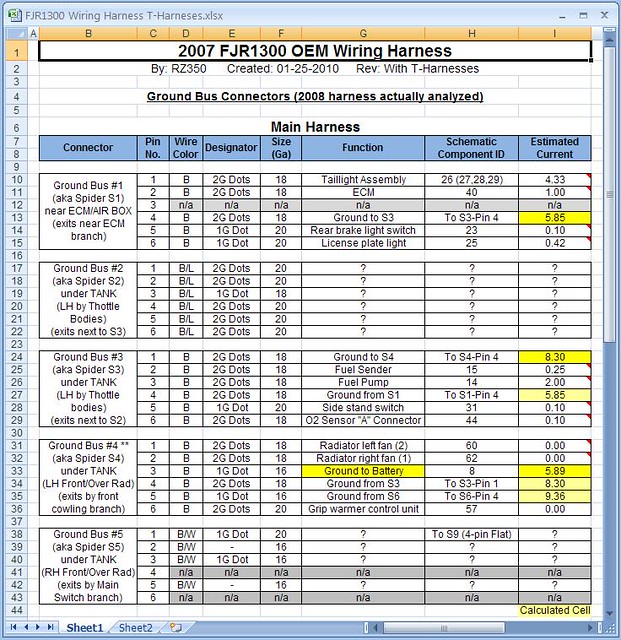

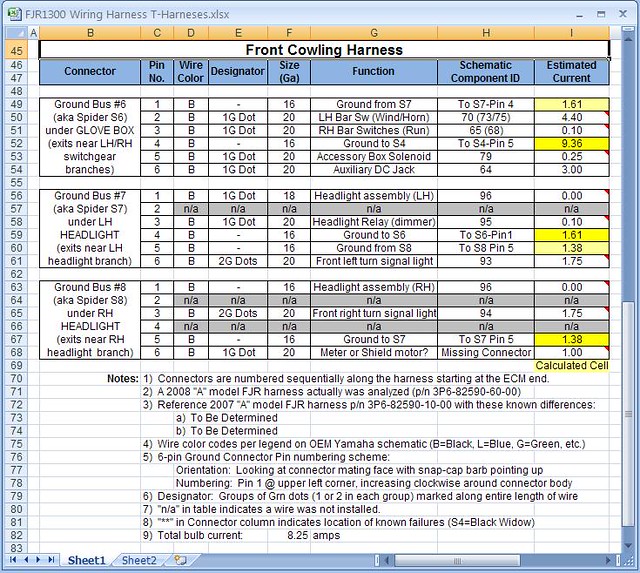

Being totally ignorant to all this, but understanding the numbers, is it so hard for Mama Yama to figger dis stuff out?? Did someone sit in front of his (or her) 3D animation computer software program and say 48 amps through that little wire should be OK... :dribble:Just out of curiousity, I decided to estimate the benefits of installing all four of road runners T-Harnesses on my FJR. I know - I need to get a life! Just thought some of you would be interested. Hopefully all of you agree with my reasoning.

Changes made to “Rev 04” calc sheet (see post #15):

- Set current coming from both Headlights and both Fans to 0 amps (each have separate ground wire now)

- Divided the total current collected at S7 by 2 (1 extra ground wire shares load on spider)

- Divided the total current collected at S8 by 2 (1 extra ground wire shares load on spider)

- Divided the total current collected at S4 by 3 (2 extra ground wires share load on spider)

ESTIMATED RESULTS:

Peak current (everything powered up), total new amperage on the individual spiders:

S1= 5.85

S3= 8.30

S4= 5.89

S6= 9.39

S7= 1.61

S8= 1.38

Here’s the old “maximum" amperage values again for reference:

S1= 5.85

S3= 8.30

S4= 40.25

S6= 22.55

S7= 14.80

S8= 7.85

The results are somewhat astounding, but make perfect sense. None of the existing spiders see more than 10 amps. Mission accomplished, in my book. Good job road runner!

Enter your email address to join: