Northwoods Snowman

Well-known member

I started this project back in the spring of 2014 and finally finished it last weekend (except for paint) and thought I should share.

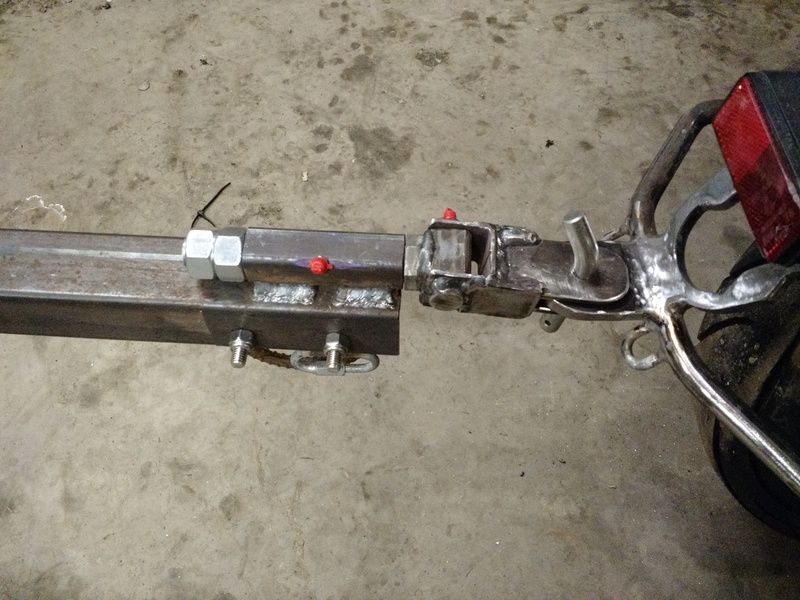

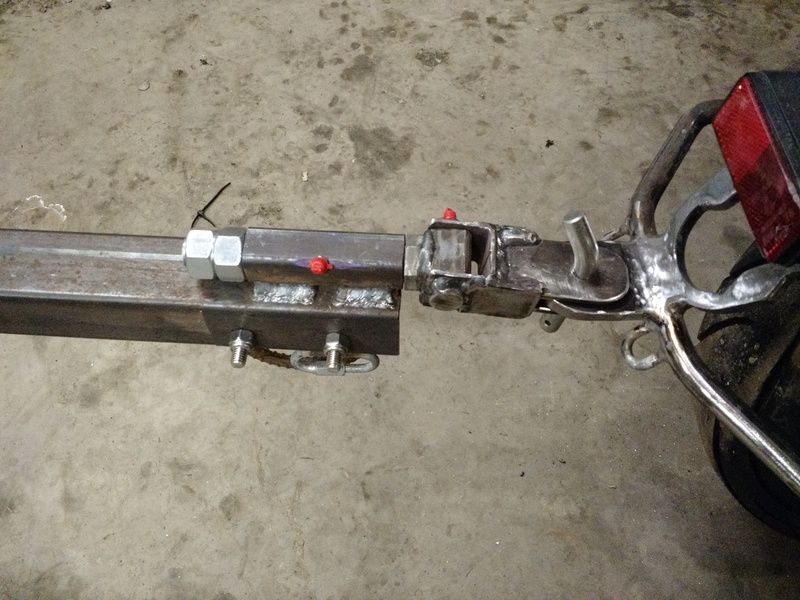

I used 2"x2" and 2"x 1" box tubing with about a 1/16" wall (can't remember the gauge). Picked up some 500# torsion axles from Northern Tool, but these thing are HEAVY! I think they are probably the same components for 2000# or 3000# axles but with softer rubber or something; the tire/hub/axle assemblies weigh 34# EACH. I decided to add an external cooler rack after the fact and then had to move the axles forward so that's why there's also some angle iron. Not as clean as I would like but empty I have 13% tongue weight and the ability of offset the cooler weight. Box is just a cheap roof box I found on craigslist. Added some lights and fenders and I've got a functioning trailer. The three-axis coupler also comes off so I an put on a ball coupler for towing behind the car.

Now I just have to wait until summer when it's warm enough to paint it up.

I used 2"x2" and 2"x 1" box tubing with about a 1/16" wall (can't remember the gauge). Picked up some 500# torsion axles from Northern Tool, but these thing are HEAVY! I think they are probably the same components for 2000# or 3000# axles but with softer rubber or something; the tire/hub/axle assemblies weigh 34# EACH. I decided to add an external cooler rack after the fact and then had to move the axles forward so that's why there's also some angle iron. Not as clean as I would like but empty I have 13% tongue weight and the ability of offset the cooler weight. Box is just a cheap roof box I found on craigslist. Added some lights and fenders and I've got a functioning trailer. The three-axis coupler also comes off so I an put on a ball coupler for towing behind the car.

Now I just have to wait until summer when it's warm enough to paint it up.