Steve in Phx

Well-known member

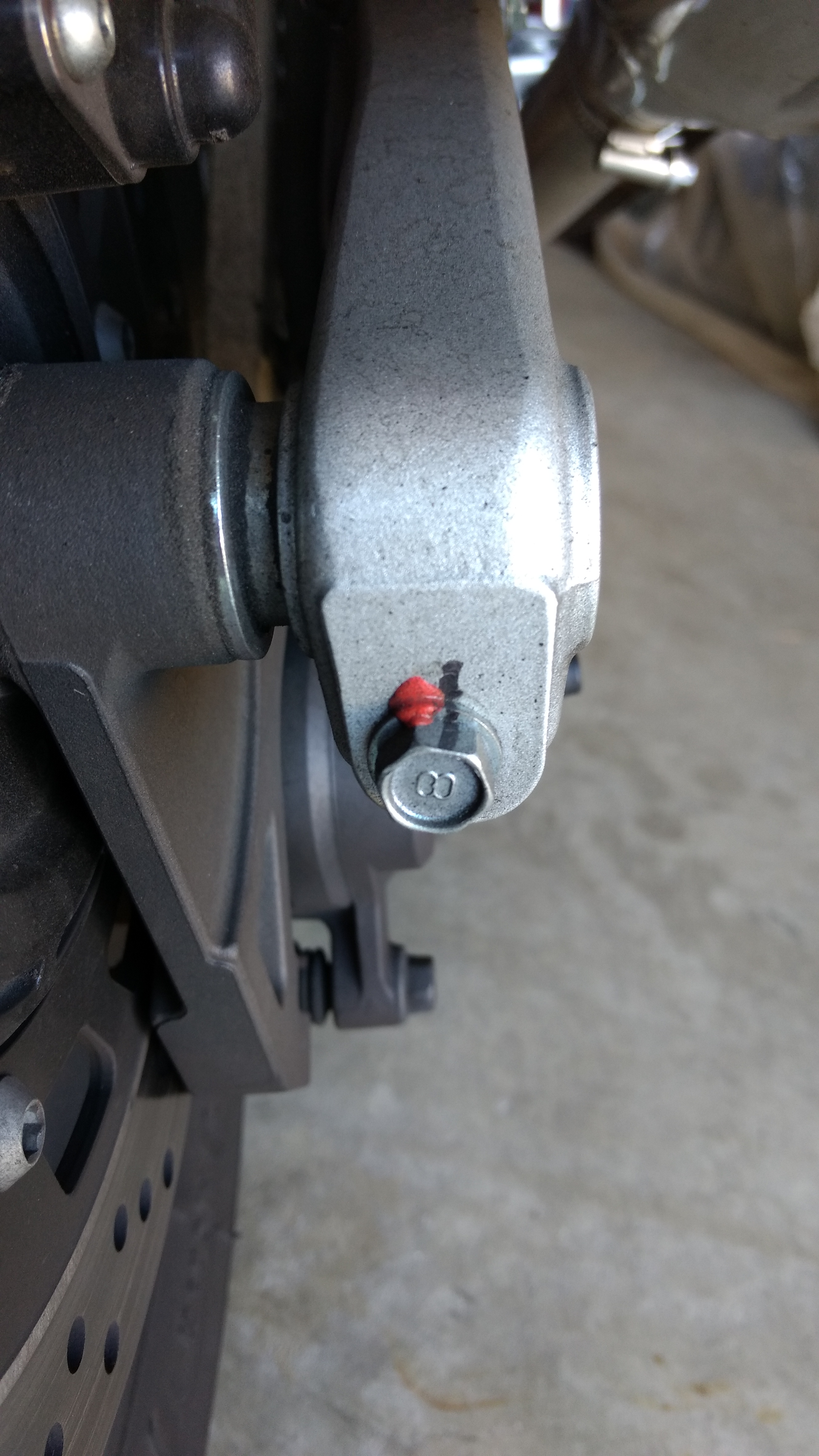

I went to change my rear tire and noticed my rear axle pinch bolt is missing. Not sure how long it's been gone.

Can anyone tell me what the pinch bolt dimensions are, so I can get a local replacement? Judging by some spare odd bolts on hand, it seems like a 8MX20 but I'm not sure of the correct length. The parts fiche doesn't specify the size but a search seems to indicate this isn't too uncommon.

https://www.fjrforum.com/forum//index.php/topic/14961-pinch-bolt-poser/?hl=%2Baxle+%2Bpinch+%2Bbolt&do=findComment&comment=181272

Also, to prevent this from happening again, would a small dot of blue loc-tite be out of the question? Or has anyone had success using a lock washer on it?

Can anyone tell me what the pinch bolt dimensions are, so I can get a local replacement? Judging by some spare odd bolts on hand, it seems like a 8MX20 but I'm not sure of the correct length. The parts fiche doesn't specify the size but a search seems to indicate this isn't too uncommon.

https://www.fjrforum.com/forum//index.php/topic/14961-pinch-bolt-poser/?hl=%2Baxle+%2Bpinch+%2Bbolt&do=findComment&comment=181272

Also, to prevent this from happening again, would a small dot of blue loc-tite be out of the question? Or has anyone had success using a lock washer on it?