2015-08-20 Nose back on

Permalink Submitted by

dcarver on Fri, 08/21/2015 - 09:24.

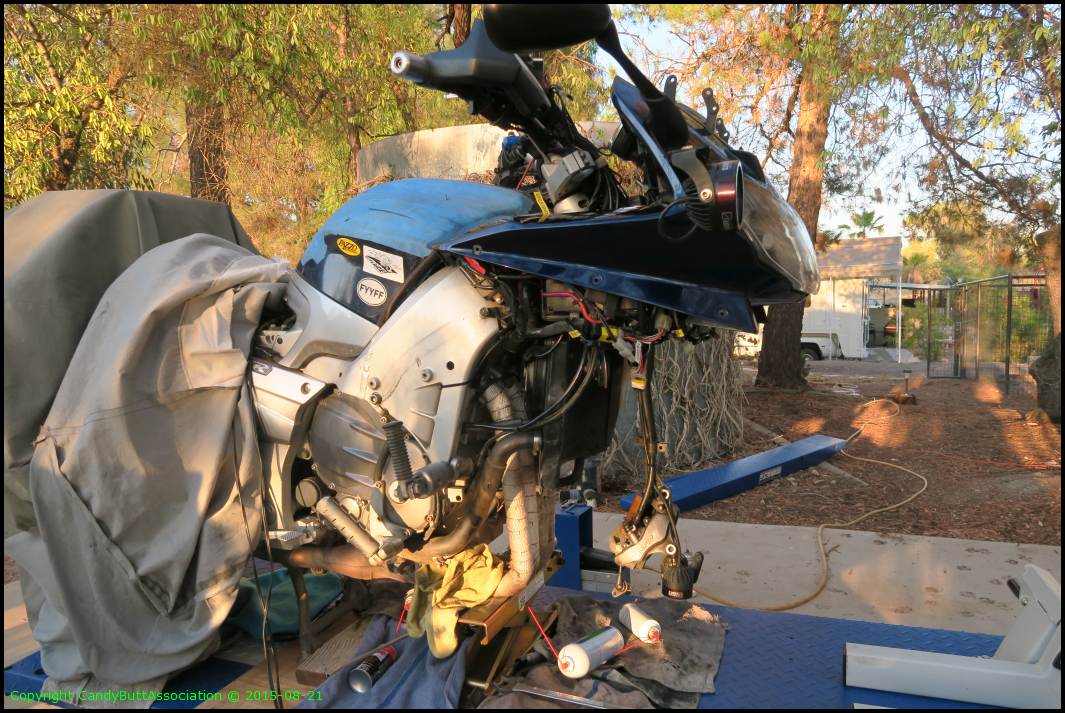

2015-08-20 Windshield Drive Maintenance and Nose Back On

But first a few pix from the cheering section, miss Molly!

She has soulful eyes

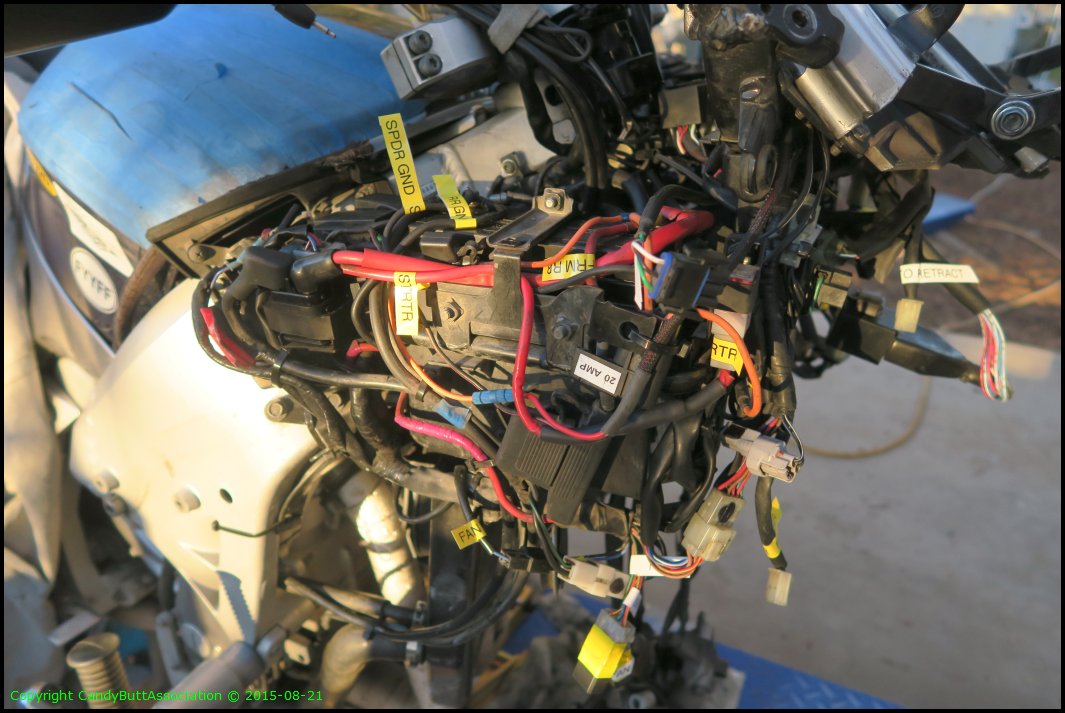

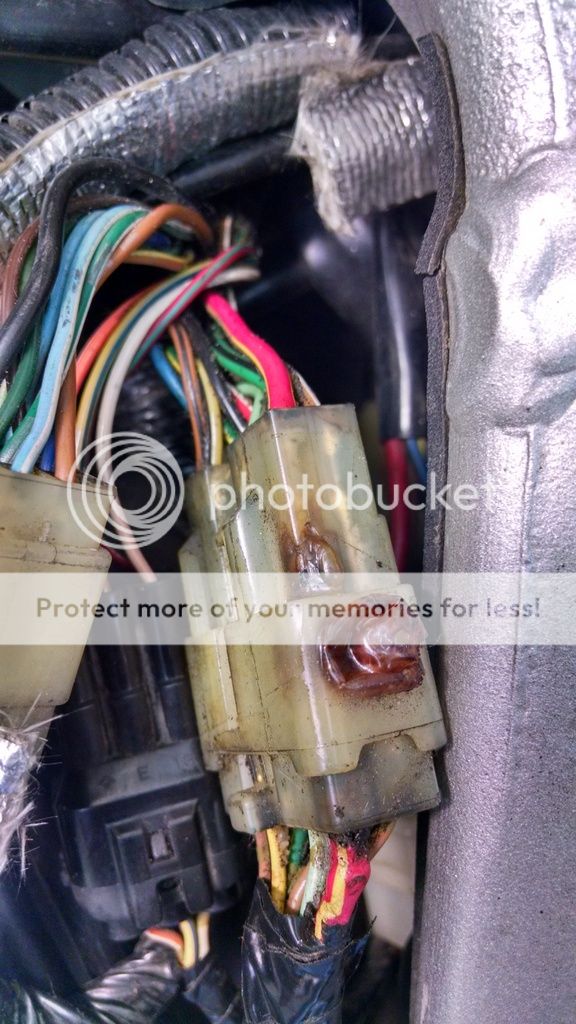

Cleaned up wiring, RHS.

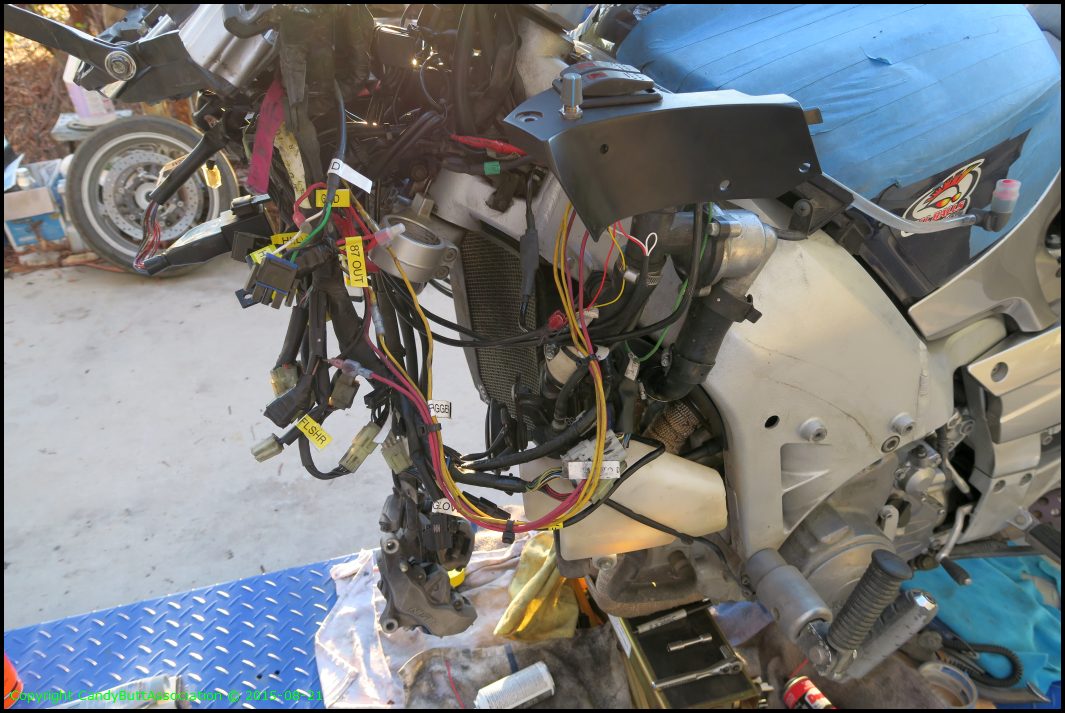

LHS wiring re-org in progress. Finally, wires cut to correct length with no 'looping'..

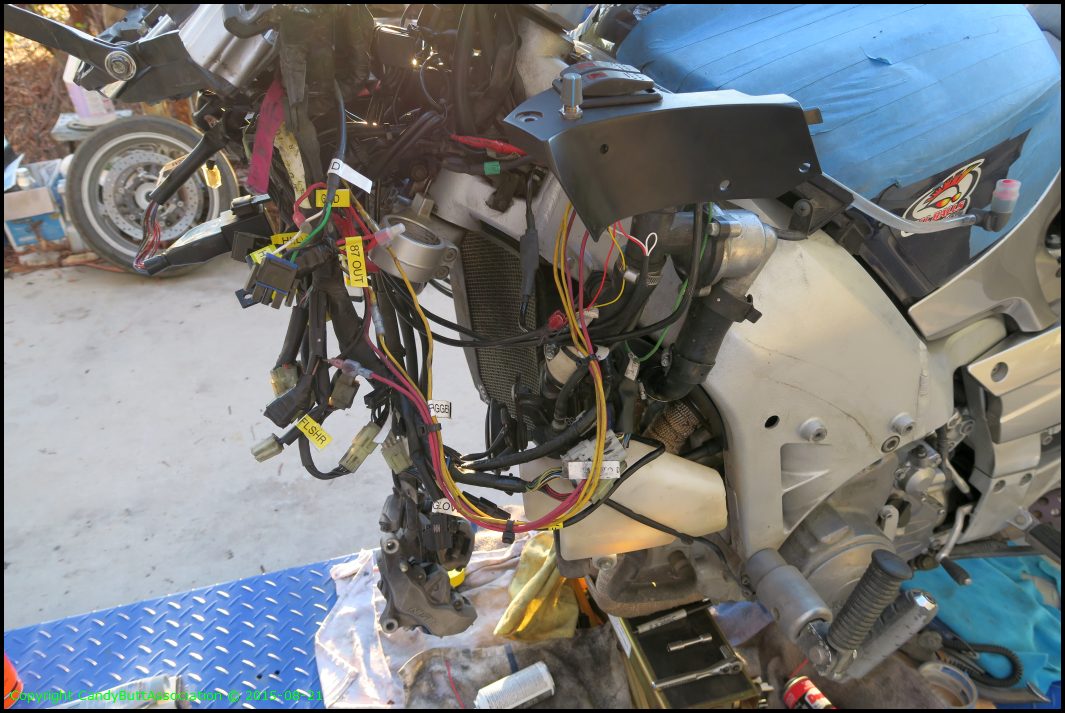

Cleaned and lubed the windshield drive mechanism.

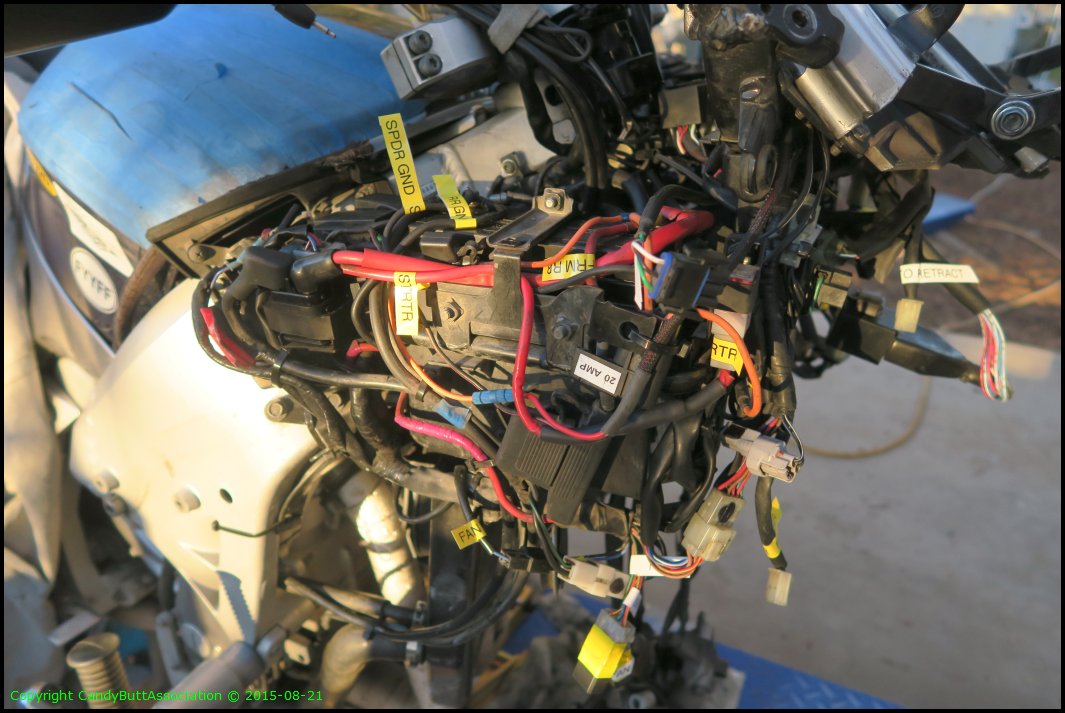

Here is where stuff is located.. for future reference.

This wiring had to move.. the big black bundle for the Clearwater lights.. The headlight nacelle fits VERY tight in this area..

On the other side, made room to get my paw into the headlight connector area for future headlight replacement work.

My fairing is broken up at the nose....both sides.

I used Gorilla tape to keep it together until adequate fasteners keep it bundled up..

Windshield drive mechanism. The grooved block... I wonder if there are replacement parts for it? This rides in the outer 'rails' allowing vertical windshield movement. I think these are worn.

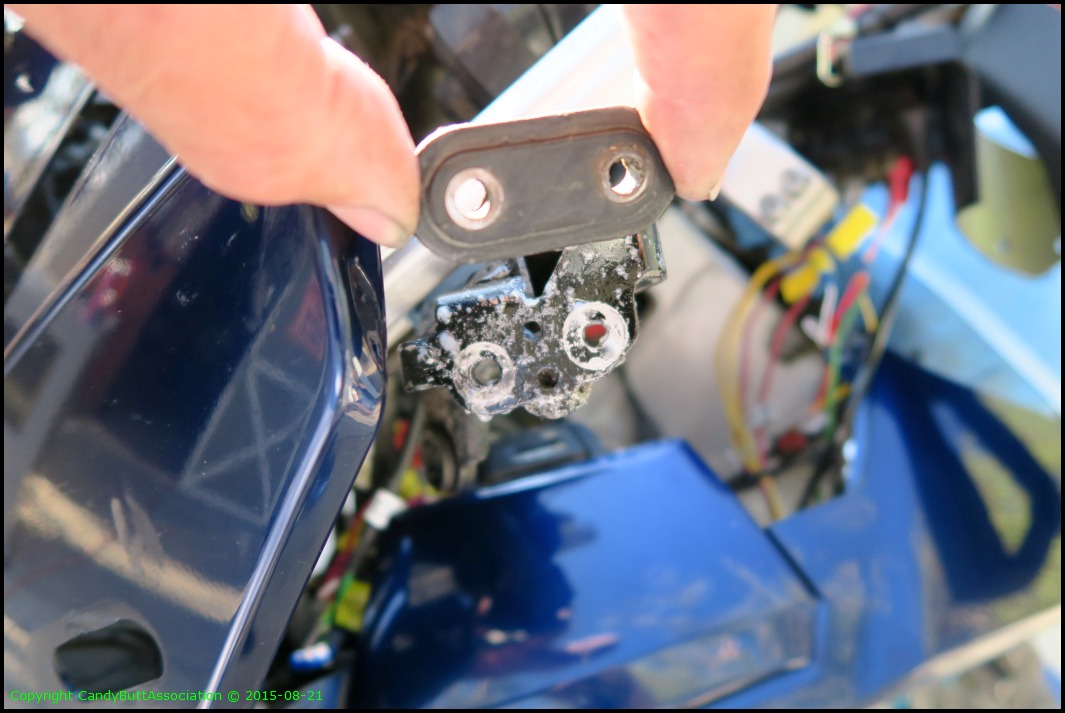

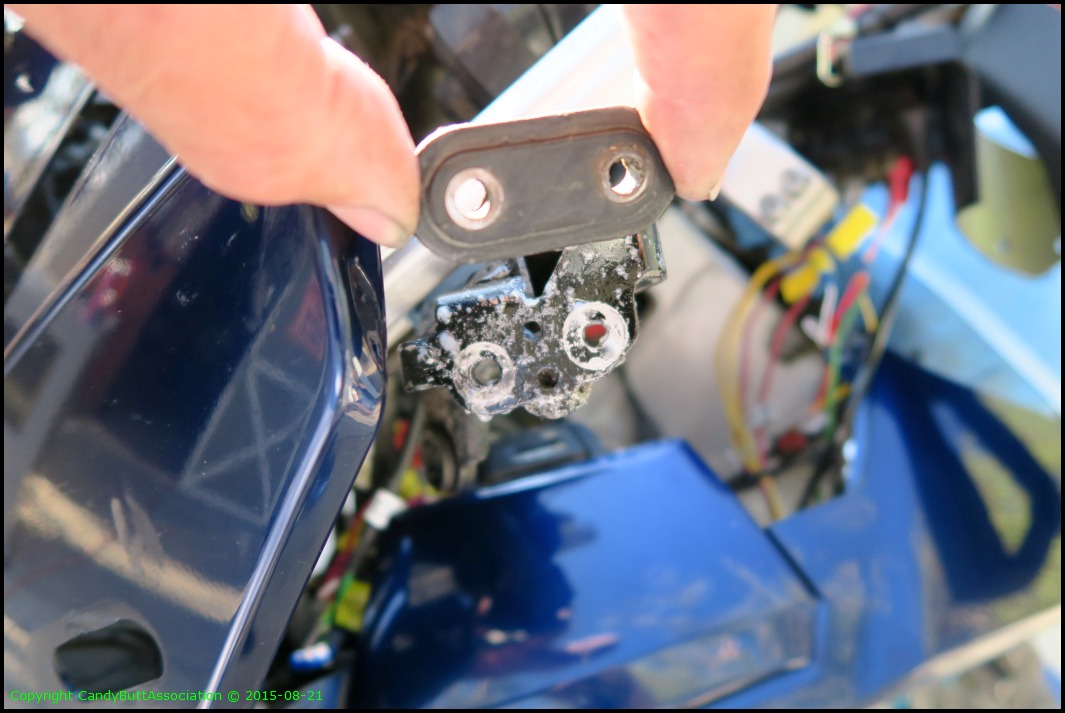

Here's a problem.. the vertical steel piece is part of the batter holder. It's supposed to be on the other side of the tab with a bolt to secure it. Evidently, my tech didn't do such a good job. ...and for this one time, I'm not the tech!

Close up.

All fixed. Had to loosen both the battery box and the front stay to gain clearance...

A front nose install tip - be sure that the mirror 'spacers' are glued to the subframe prior mounting the nose. DAMHIK.

I used this stuff to glue the rubber to the aluminum.

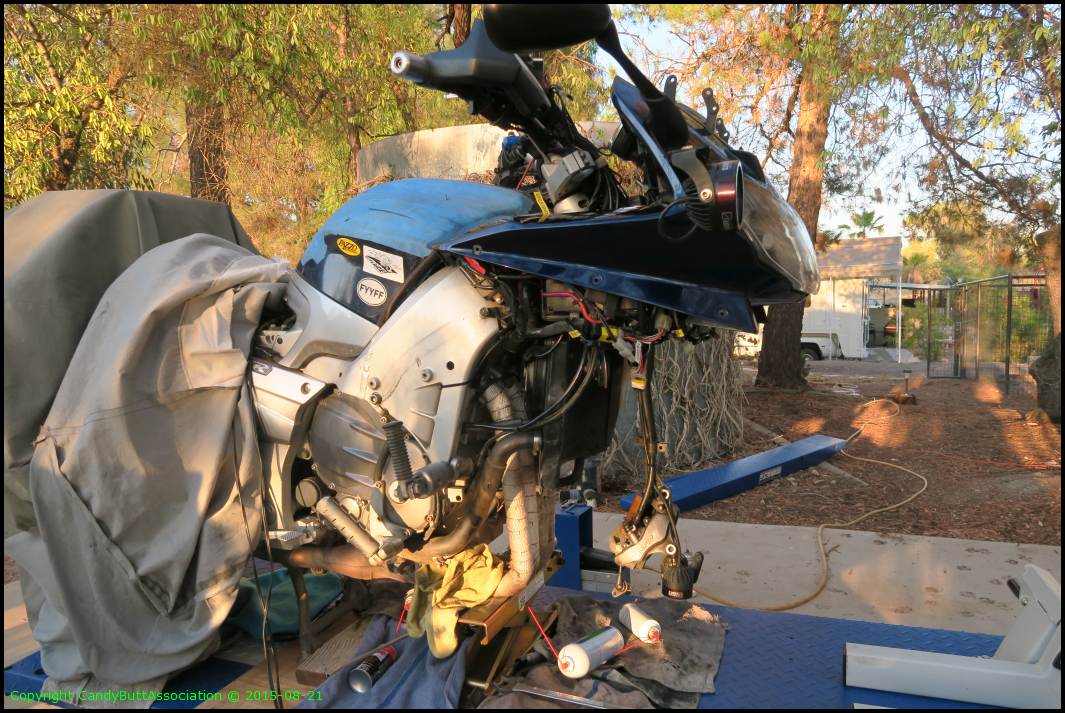

I had to install and remove the nose at least a dozen times.. I had re-routed wiring to 'clean it up' and too bad too sad the wiring interfered with things like the headlight nacelle, headlight adjustment mechanism, etc.

It felt good to get the nose back on..

It

She's almost ready....

The front forks are awaiting parts, sigh. Recall the original reason for starting this job was a slow cranking speed then no crank at all. Then discovered the leaky right fork seal.. Then decided to visit all the connectors.. Then label all the connectors. Then clean up wiring. What the hell is wrong with me?

...more to come