Yesterday on my way down to AR my ABS light starts flashing as I am driving down the road. I pull into a gas station and check the bulbs and other items I Googled. Everything seems in order. With no brake lights I abort my weekend ride and head home.

On the way home I notice my wind shield will not retract. I stop at a gas station to charge my cell and now the glove box wont open. This AM I check and my horn does not work either. All classic signs I have a harness issue.

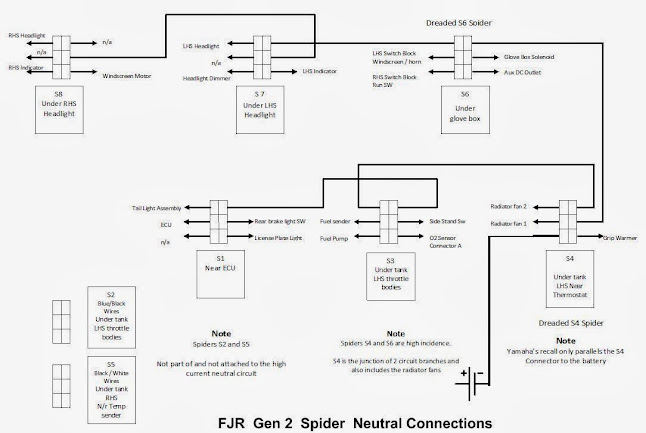

This AM I research the issue and everything leads to the ground fault problem. Search the forum and find a How-to to check all eight connectors. I check all of them, but find nothing melted.

So my question is. Can I still have a ground fault issue? The symptoms would suggest yes.

The person who I bought the bike from took the bike to the dealer for the recall, but I can't tell if they really did anything.

Suggestions?

Thanks,

Jeff

Spider Bit......I think

On the way home I notice my wind shield will not retract. I stop at a gas station to charge my cell and now the glove box wont open. This AM I check and my horn does not work either. All classic signs I have a harness issue.

This AM I research the issue and everything leads to the ground fault problem. Search the forum and find a How-to to check all eight connectors. I check all of them, but find nothing melted.

So my question is. Can I still have a ground fault issue? The symptoms would suggest yes.

The person who I bought the bike from took the bike to the dealer for the recall, but I can't tell if they really did anything.

Suggestions?

Thanks,

Jeff

Spider Bit......I think

Last edited by a moderator: