escapefjrtist

Searching for Dry Roads

...

Last edited by a moderator:

Heat treatment made it too brittle; sacrificing toughness for hardness?I would more suspect to think the force of the constant up and down motion of the shock is what is causing this failure. They need to redesign this clevis part. I don't think the bolt has anything to do with it. Having both crack on opposite side would tend to support this theory. Then again I am just a machinist and backyard designer not an engineer.

Dave

Clevis dammit! Learn something.I hear what you are saying G, but I simply could not get the Clovis to spin out without unbolting the top. I fiddled with it for at least 15 min two separate times. And then just figured I had to unbolt the top. The shock spring was hitting the inside of the "hole" in the bike. I couldn't pivot the shock far enough to get it past the bottom attachment point. I am not doubting you, but I apparently couldn't find the sweet spot to get that done. I am out in the garage now cleaning all the pivot points and greasing them up. Ready to install the new part. Well I am mostly enjoying the 75* weather and some Jim Beam, but it's all good.

If that was the case, it would be a general error showing it's warts in a more widespread manner.Heat treatment made it too brittle; sacrificing toughness for hardness?I would more suspect to think the force of the constant up and down motion of the shock is what is causing this failure. They need to redesign this clevis part. I don't think the bolt has anything to do with it. Having both crack on opposite side would tend to support this theory. Then again I am just a machinist and backyard designer not an engineer.

Dave

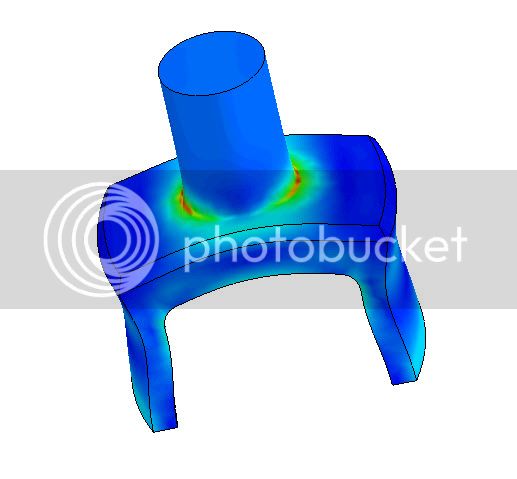

I believe this is what I was inferring to but in a much simpler explanation. As bounce said the material may be to hard and prone to cracking. A more forgiving material choice would help also. Hopefully this informatoin is being passed along the Penske.Now, having stated all of this, here is my dilemma. The failure on Josh's part (and the others I've seen on this and other threads) looks like what I've seen in other test after the metal fails from fatigue. Repeated and numerous (maybe a million) cyclic loadings past the proportional limit, but below the elastic limit. If that is true, then it failed from the cyclic loading of the shock compression and rebound. Again, the fix would be a stronger (and less brittle) material, along with thicker proportions.

I think this is the most likely answer, although squeezing too much with the lower mount bolt may contribute somewhat. See pic of the clevis on my RaceTech, much better design. A quick look of the OEM Gen3 clevis shows it is perhaps slightly better than the Penske.The radius between the last thread just before it becomes the top of the Clevis is the culprit. That's the weakest point. If it's going to crack, that's where it'll happen on either side. That spot is under both shear and tension.

Clevis dammit! Learn something.I hear what you are saying G, but I simply could not get the Clovis to spin out without unbolting the top. I fiddled with it for at least 15 min two separate times. And then just figured I had to unbolt the top. The shock spring was hitting the inside of the "hole" in the bike. I couldn't pivot the shock far enough to get it past the bottom attachment point. I am not doubting you, but I apparently couldn't find the sweet spot to get that done. I am out in the garage now cleaning all the pivot points and greasing them up. Ready to install the new part. Well I am mostly enjoying the 75* weather and some Jim Beam, but it's all good.

Although I haven't checked.... the shoulder on the bolt should be greater than the thickness of the Penske clevis..... again would prevent overclamping as any contributor to the stress problem.I would suggest that there is not supposed to be ANY side force on the clevis when it is tightened! No clamping force at all. The spacer should be sized such that it prevents the sides of the clevis from being pulled in. The correct shoulder bolt, the right spacer and proper installation are needed.

Life is good, and it appears I may be spared shipping the broke part back. BTW the FSM calls for a 29 ft-lb torque on that bolt.Tom,

Glad you caught this before anything happened.

Yes we will cover this under a warranty claim. We will get one shipped out to you. Is that your shipping address you included in your email?

Thank you

Eric Trinkley

Motorcycle Department

Penske Racing Shocks

Custom Axis Shocks

150 Franklin Street

Reading, PA 19602

United States

Office: 610.375.6180

Fax: 610.375.6190

www.penskeshocks.com

www.customaxisshocks.com

Dave, They did say that they want the part back for analysis. And to keep it out of the marketplace.I believe this is what I was inferring to but in a much simpler explanation. As bounce said the material may be to hard and prone to cracking. A more forgiving material choice would help also. Hopefully this informatoin is being passed along the Penske.Now, having stated all of this, here is my dilemma. The failure on Josh's part (and the others I've seen on this and other threads) looks like what I've seen in other test after the metal fails from fatigue. Repeated and numerous (maybe a million) cyclic loadings past the proportional limit, but below the elastic limit. If that is true, then it failed from the cyclic loading of the shock compression and rebound. Again, the fix would be a stronger (and less brittle) material, along with thicker proportions.

Dave

Off Topic. We need a Pointer Dog to get you back on Point!Clevis dammit! Learn something.I hear what you are saying G, but I simply could not get the Clovis to spin out without unbolting the top. I fiddled with it for at least 15 min two separate times. And then just figured I had to unbolt the top. The shock spring was hitting the inside of the "hole" in the bike. I couldn't pivot the shock far enough to get it past the bottom attachment point. I am not doubting you, but I apparently couldn't find the sweet spot to get that done. I am out in the garage now cleaning all the pivot points and greasing them up. Ready to install the new part. Well I am mostly enjoying the 75* weather and some Jim Beam, but it's all good.

CLOVIS =

At roughly 13,500 years old, age and brittleness of material will be prone to failure. However, really a leap forward in design for the time.

If you look close Harley still uses a similar design on their FLHTSDOUCHE King Road Hog.

Enter your email address to join: