I´m new here, just bought a 2006 FJR and it only has 7000 miles on it.

It has been standing for 2 years and I discovered after a short drive that it was leaking forkoil from the left compression adjustment. Not a lot but I really want to fix it. Anyone that knows how to?

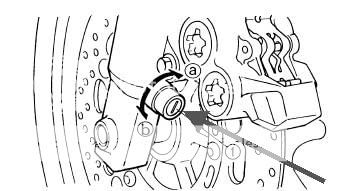

And, as I know you all know, Gen 1 has a different kind off adjustment, a screwed in aluminum thing with a brass screw. Gen 2 has, what it looks like, a pressed aluminum socket/sleeve with a brass screw.

Oil seeps out between the brass screw and the socket/sleeve.

Must be a dry o-ring or such in there...

Regards from Sweden

It has been standing for 2 years and I discovered after a short drive that it was leaking forkoil from the left compression adjustment. Not a lot but I really want to fix it. Anyone that knows how to?

And, as I know you all know, Gen 1 has a different kind off adjustment, a screwed in aluminum thing with a brass screw. Gen 2 has, what it looks like, a pressed aluminum socket/sleeve with a brass screw.

Oil seeps out between the brass screw and the socket/sleeve.

Must be a dry o-ring or such in there...

Regards from Sweden