Hornet Pilot

Viper Pilot

By the way, EXCELLENT job of tear down and documenting the FJR engine internals. Good on ya!

Agree. A dial caliper and operator won't have the ability to measure this. Plastigauge the only way to go here.A bit more about the balancer.

The adjustment is just for gear lash and operating noise, it does nothing for the actual balancing. Also, the FSM doesn't mention this but there are TWO alignment marks and it's easy to align to the wrong mark which results in an engine that runs like a Sherwin Williams paint shaker.

Depending on the ambition level of hppants, he could use a Plastigauge kit and measure the rod bearing's free play. With the rod cap removed, clean the journal and place a strip of Plastigauge across the journal. Put the rod cap back on and torque to spec. Remove the rod cap and see that the Plastigauge strip will have been squished flat. Use the gauge supplied in the kit to measure the width of the squished plastic. The width is directly proportional to the clearance and read on the gauge in thousandths of an inch.

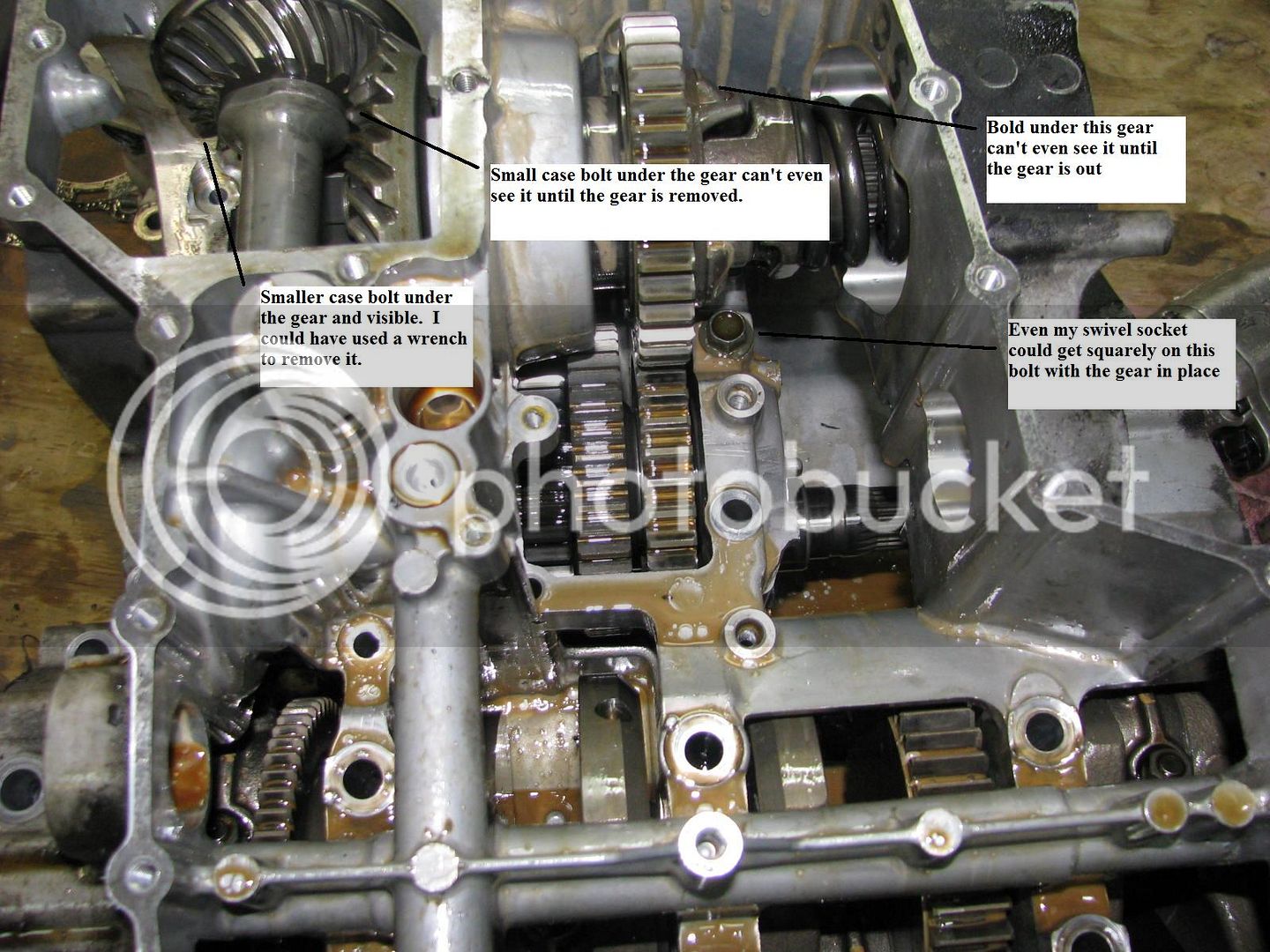

My apologies for the confusion, what I meant was you only had to remove the output gear (the one on the far left in that picture with the u-joint)Goat - I'm at a loss at to how you could remove the last 4 bolts (especially the last 2) to split the case without removing the output gearing setup? Take a look at this picture - these are the bolts I was referring to. Again, I'm not arguing, but trying to learn.

Also, no groove felt with my fingernail on any of the crank journals. I think the crank is good.

The more I look at those bearing pics and the 'white milk slurry' in the sump and oil pump, the more convinced I am that MADDAD has the right theme with what went wrong with this engine. Depending upon what the rod bearing clearance measurements turn out to be, I think it is very possible that if the source of the water in the oil was found and repaired and the engine cleaned of the water logged oil and fresh oil added, this enging might run for another 100K. I think the noise that was heard were the rod bearings being tortured due to the watered down oil slurry in the sump. That score mark on the #3 rod bearing doesn't look catastrophic to me just from the photos. Might be wrong but I'm a sceptic!!

that is a 'skeptic'!

Enter your email address to join: