WC,And don't forget to heed the requirements for baffling and venting in your design. Folks have failed Tech Inspection before for these items.

I have never ralley'd, but want to be able to, so this brings up another question I have been wanting to put to you about baffling.

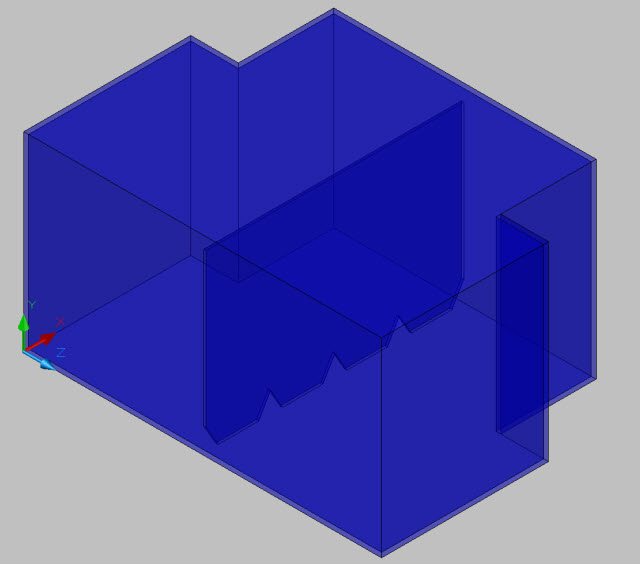

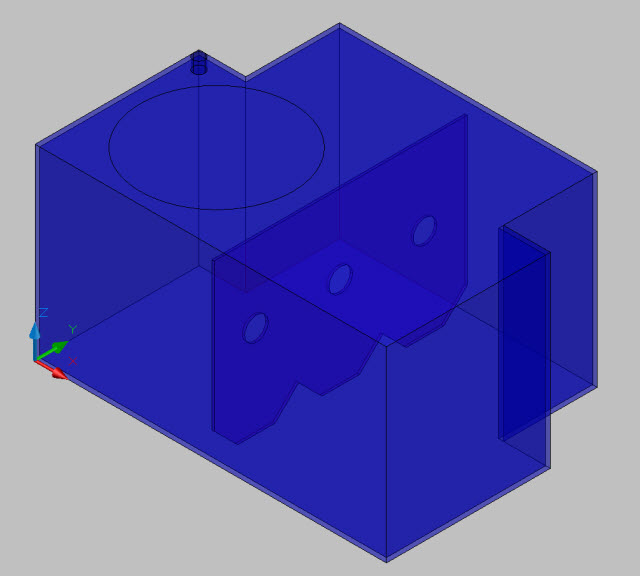

The "stock" cells often come with foam. I had a 5 gallon cell on another bike and had constant problems with bits of it plugging/restricting flow (I did use a filter). An old circle track guy in a NAPA store said that what they did was remove the foam (for the same reason) and for baffles used the plastic 1 qt oil containers that have been cut here and there so they don't retain/pocket fuel. It really is a good solution IMO and want to know if you've seen this and think it would be legal for IBA/something you'd pass.

I can send pics if you want to show you what I mean. On the 5 gallon Summit cell I basically just cut and installed as many as I could get in there. Fuel don't slosh and no "bits" of stuff in the fuel line/filter as the foam did.

If I went with the 4 gallon cell for the FJR, I had planned on doing this to it, so, inquiring minds want to know...