Dan S

Well-known member

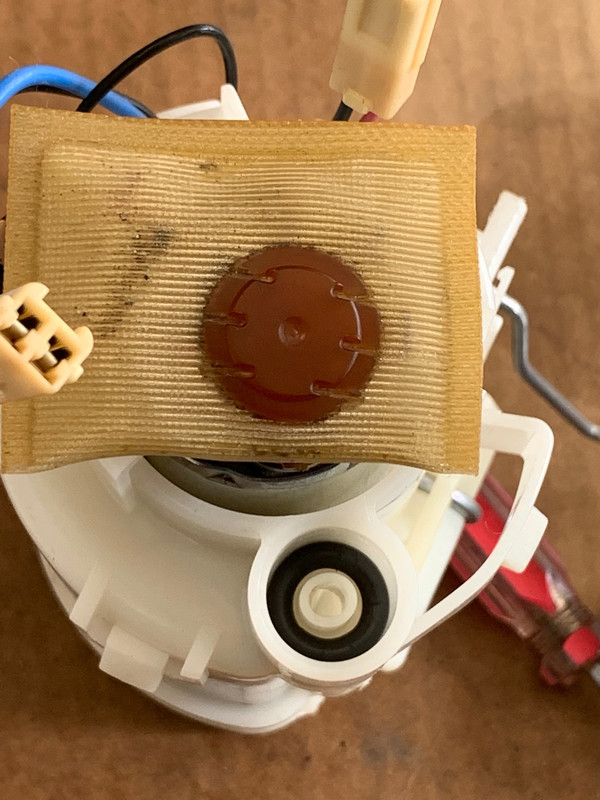

To help you avoid reading this entire tread just to find out in the end that this is very unlikely the answer to a similar problem you are having. In the end the problem was because of a mistake I made when reassembling my fuel pump way back about 2 years before the "running crappy" cold start problem started. Skip all the way down to the bottom to find a description of my stupid mistake.

Below is how this thread started:

I've been discussing this ad-nauseum on another thread because my problem started when I changed the coolant hoses to the high idle wax valve. Ross Kean has been very helpful in that conversation but here I'm going to try and expand the discussion because it seems to be caused by something other than the coolant hoses. Below is a video of where I am right now. In summary, there are no error codes, all the self diagnostic codes seem to be reading and testing correctly, all spark plugs look ok, high idle (wax valve) seems to function correctly, but it is running very lean especially when cold.

The supplementary service manual is helping a lot. Looks like maybe the problem is the O2 sensor. It's strange that it does not show up as a diagnostic mode.

https://www.manualslib.com/manual/802254/Yamaha-Fjr1300-S.html?page=24#manual

next I'm going to unplug the air box temp sensor and see if it will run right in open mode.

Below is how this thread started:

I've been discussing this ad-nauseum on another thread because my problem started when I changed the coolant hoses to the high idle wax valve. Ross Kean has been very helpful in that conversation but here I'm going to try and expand the discussion because it seems to be caused by something other than the coolant hoses. Below is a video of where I am right now. In summary, there are no error codes, all the self diagnostic codes seem to be reading and testing correctly, all spark plugs look ok, high idle (wax valve) seems to function correctly, but it is running very lean especially when cold.

The supplementary service manual is helping a lot. Looks like maybe the problem is the O2 sensor. It's strange that it does not show up as a diagnostic mode.

https://www.manualslib.com/manual/802254/Yamaha-Fjr1300-S.html?page=24#manual

next I'm going to unplug the air box temp sensor and see if it will run right in open mode.