dcarver

Well-known member

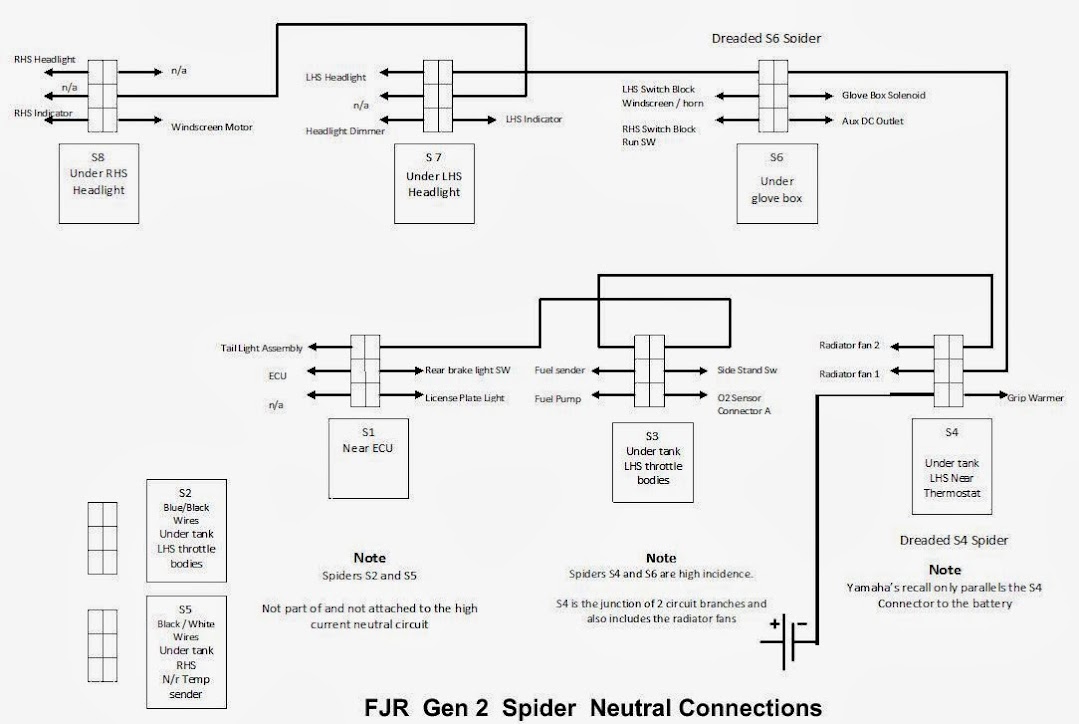

Downloaded and save..Road map.

Along side the ECU S1

2 near the fuel rail connection LHS S2 S3

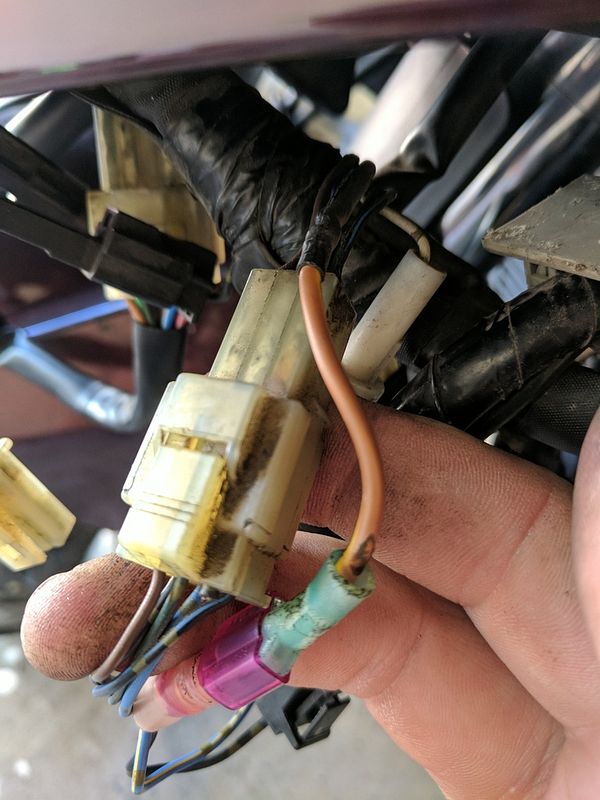

1 at the front under the tank, LHS near the radiator hose, the dreaded S4

1 at the front under the tank, RHS near the water temp sensor S5

1 under the LHS nose cone of the bike, below the glove box S6

1 behind the LHS headlight panel S7

1 behind the RHS headlight panel S8

The S3 and S5 have only low current sinking.

Tip 'o the hat to Queensland Ken.