My last part finally arrived yesterday morning. My mind was too distracted (from other things) for doing any office work, so I decided to install the clutch upgrade into my FJR yesterday afternoon instead.

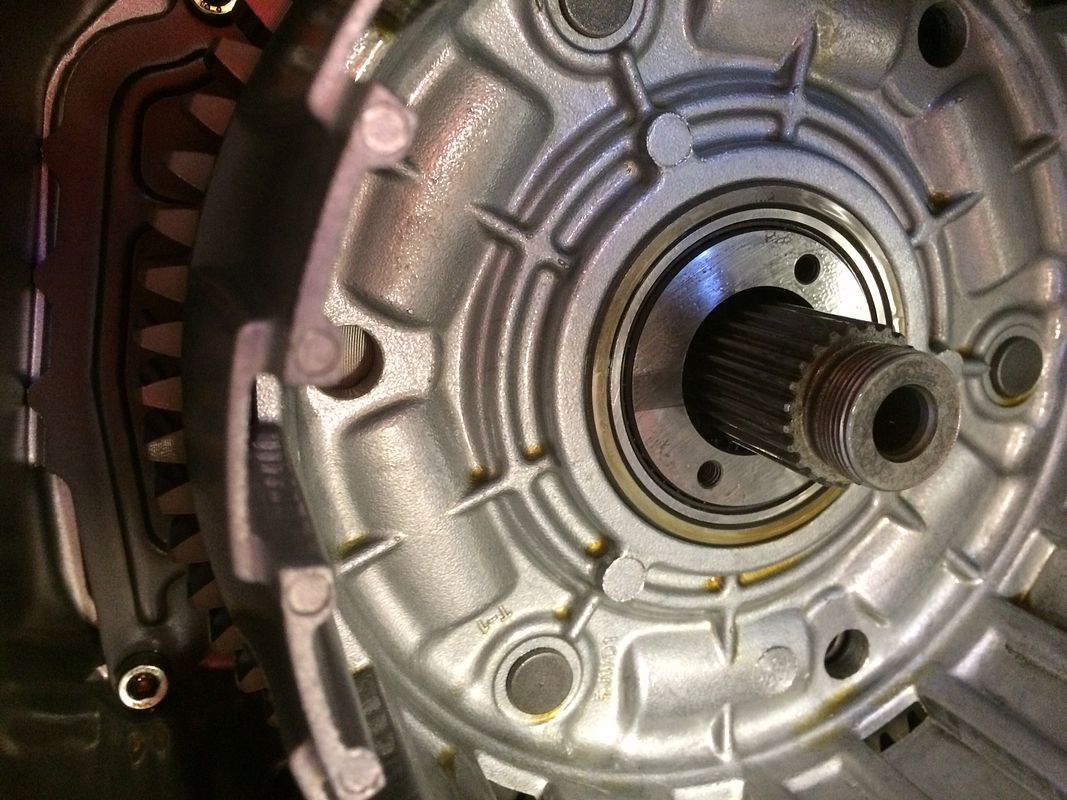

Overall, the old clutch removal, and new slipper/assist type clutch install, was all pretty straightforward. I did not drain the oil and that was no problem as expected. I also left the bike on the side stand for the entire process to make it easier to work on, and that had the bonus of keeping the pesky little steel push rod ball down in it's hidey hole. In fact, I couldn't get it out with a magnet, so I guess it must be stainless? I just made sure to eyeball that the ball was still there before reassembling everything.

Using the "transmission in 5th gear / foot on the brake pedal" trick worked like a charm to get the hub nut off. Yes, there is some motion from that middle gear spring when torquing on the clutch hub this way, but it is pretty small and inconsequential, and more importantly, the bike doesn't move.

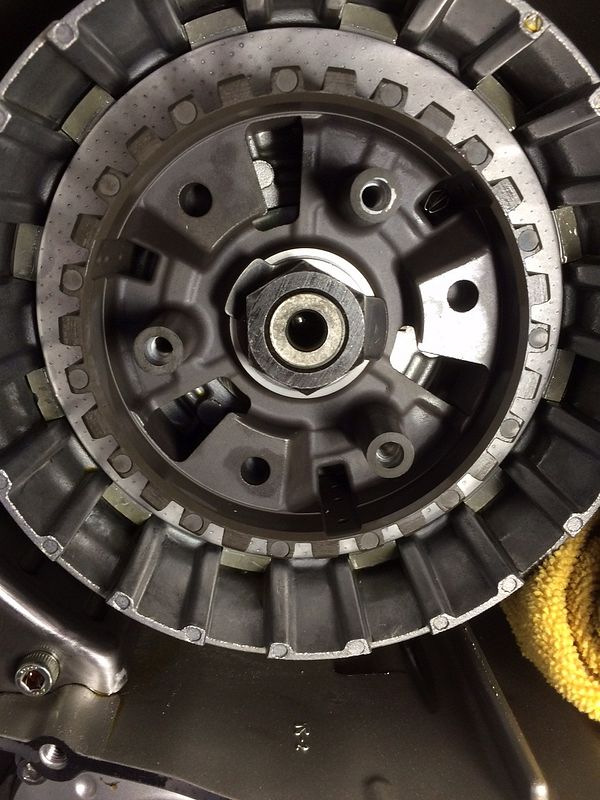

I found that all of my friction plates were slightly wet with oil; none were dry. Of course I had no real complaints about how my old clutch was operating, so maybe this is why?

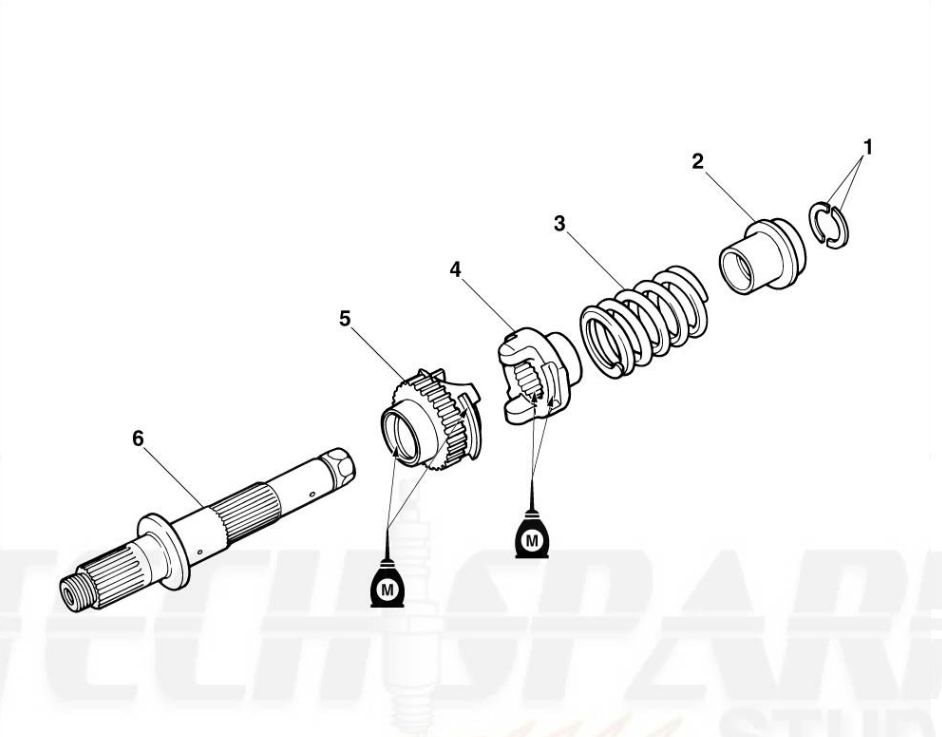

I opted not to replace the "Spacer 1" (p/n B88-16181-00-00) because pulling that out meant removing and reinstalling the clutch basket, which otherwise didn't need to be removed. Comparing what I could see of the old one to the new one, I can't see any difference. There are no new holes to allow oil flow, just the two blind, threaded holes in the outer face that you would thread a puller tool into.

Since I knew that Kaleria had left that part alone in his, and that this had worked fine for him, I decided to follow suit. So, save yourself $25 and don't bother ordering that part.

I also took some photos of the big flat washer that goes on between Spacer 1 and behind the clutch hub, and there are big recessed grooves milled into its surface to allow oil to migrate to behind the clutch hub. I don't really see how this would help to lubricate the friction plates all that much, but I guess every little bit is good.

Back side of big washer

And front side with washer in position

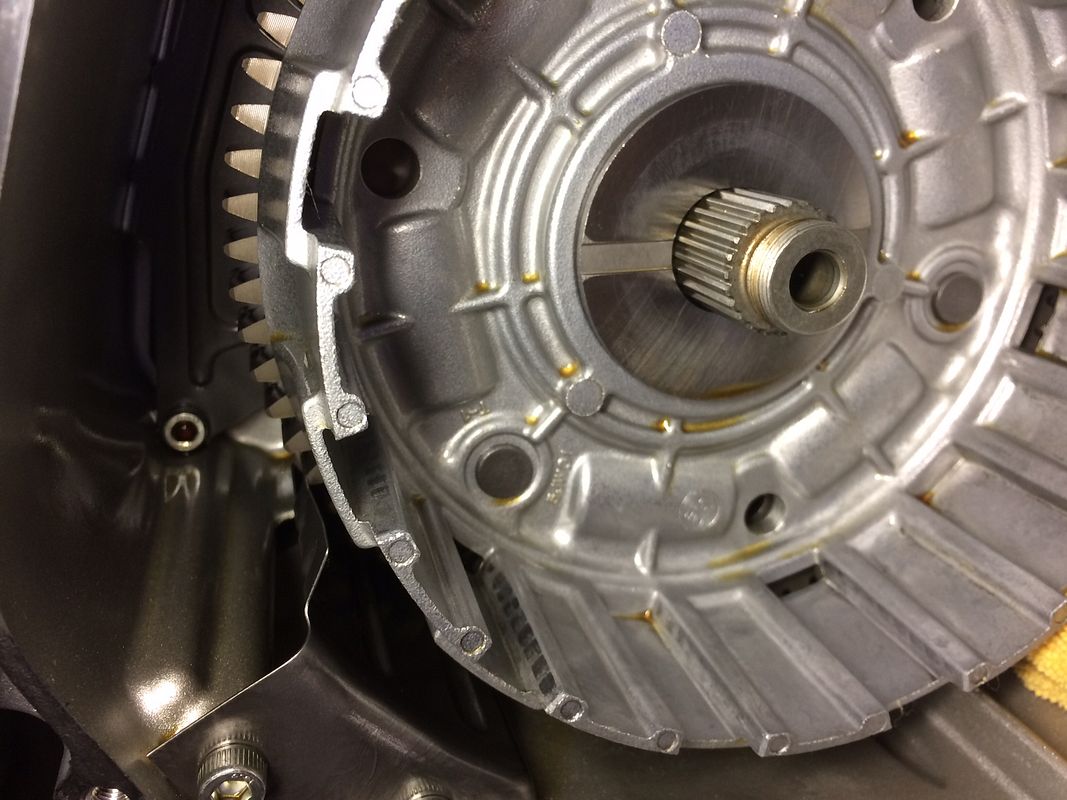

I ended up torquing and un-torquing the 30mm center hub nut several times (65 ft lb) to re-position the locking washer on the splines so that at least one of the two tabs would line up with a flat of the nut, but the other side won't anyway.

I used a large pair of channel locks to fold the tabs over both the flat and point of the nut (sorry forgot to take a pic of that). As Kaleria mentioned previously, you

do need to fold up both tabs to clear the slipper ramps of the new clutch cover. I tested that and found that this is true.

Before buttoning things up, I tested the clutch to make sure everything was moving freely and it was disengaging completely.

The gasket had stayed stuck onto the clutch cover, with very little being left behind on the engine case, so I didn't bother with the new gasket. So far, no leaks. If it does I'll pull the cover, scrape off the old and replace it with the one I bought, but I've gotten away with doing this on other engine cases many times before. Buying the gasket is the umbrella insurance policy that ensures the old gasket will survive.

One note for those that also have them, I did have to remove and replace the right side T-Rex engine guard to get at the clutch. That may have been more of a pain than anything else in the entire upgrade.

Now, for the results...

Testing set-up

Using my Zebco "De-Liar" fish scale, I measured the force that it took to pull the clutch lever before and after the upgrade. I marked a spot towards the end of the lever with electrical tape to be sure that I was pulling from the same place, and also to protect the lever from being scratched by the EBC Clutch tool that I was using to pull around the hand grip. I kept the pull perpendicular to the handle bar and recorded the maximum reading (before hitting the bar) several times.

Maximum before: 13.5 pounds

Maximum after: 11.5 pounds

So, there is a measurable difference, but I do not think this accurately reflects the

tangible difference because these were the maximums, and that happens when the lever is almost all the way in to the handlebar. The difference in "feel" is far more than the 15% difference in the maximum readings. The new clutch seems to be much lighter earlier in the pull than the original. When shifting out on the road, I seldom pull the lever all the way in to the bar, but rather only about half way, just enough to slip the clutch as the shift is being executed.

We'll have to have some other local 3rd Gen owning NERDS do some side by side, subjective analysis, but I would say the difference in clutch pull is more significant than 15%.

The other thing I observed about the new clutch is that is seems easier to slip it gracefully and gradually than with the original one. It feels as if the friction zone is a larger part of the lever throw, which makes some sense since the springs are weaker, and the "assist" ramps do not come into play until very near full engagement. I actually moved the lever out one notch from where it was previously to put the engagement point at the same distance from the bar as before. This may also be due to the fact that the plates have not fully bedded in yet, so they may be slipperier than they are after they have all seated themselves together.

As for the slipper function, that is less tangible than I expected it to be. Downshifting, even aggressively, it doesn't

feel like it is slipping the clutch at all. In my post upgrade test ride I was riding along at ~4k rm in 3rd gear and double downshifted to 1st and pretty much dumped the clutch. There was the normal, massive amount of engine braking, and the rear tire chirped a little bit, but did not lock up fully. I seriously doubt that that would be enough to save your bacon if you made a double downshift coming into a corner hot.

All of the above may be tempered by the fact that the mating ramps on the clutch hub and pressure plate have not been broken in yet either. Those parts were conspicuously un-machined castings, with sandblasted-like surfaces.

Perhaps as these wear in against each other the slipper and assist actions will become more pronounced. Why these parts were not machined is anyone's guess.

In retrospect, do I like the new clutch better? Yes. I like the progressive feel and lighter pull better, but am somewhat disappointed in the slipper function. Is it worth ~ $300 and a couple of hours of wrenching to get the slipper assist clutch? Of that I am not so certain.