I'mAllIn

Well-known member

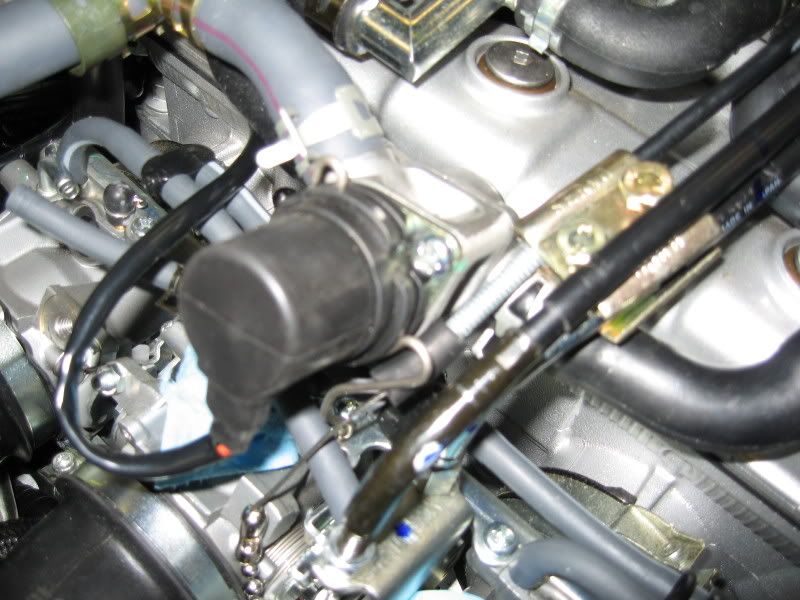

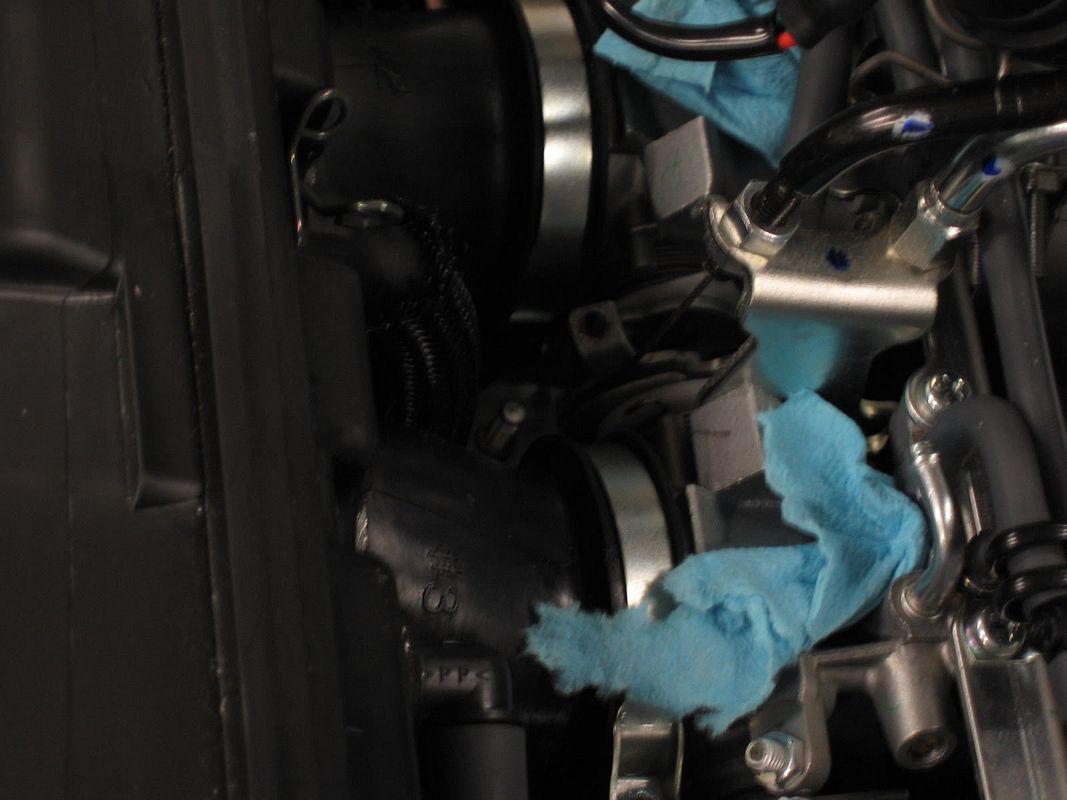

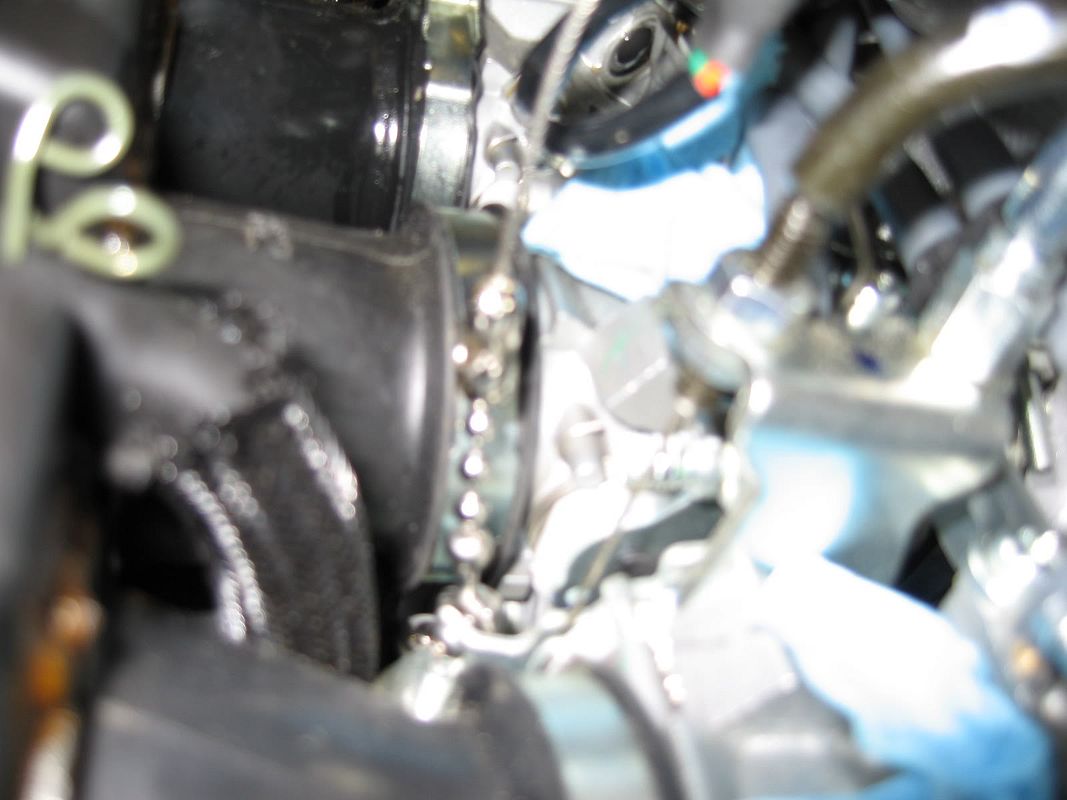

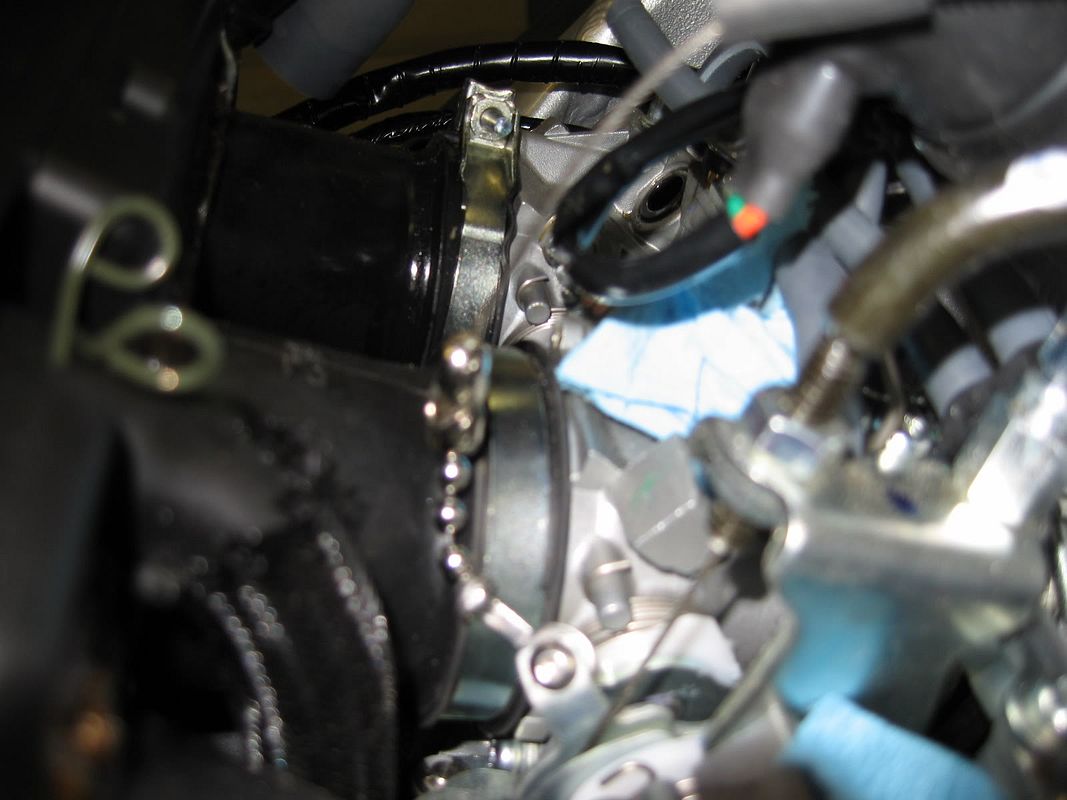

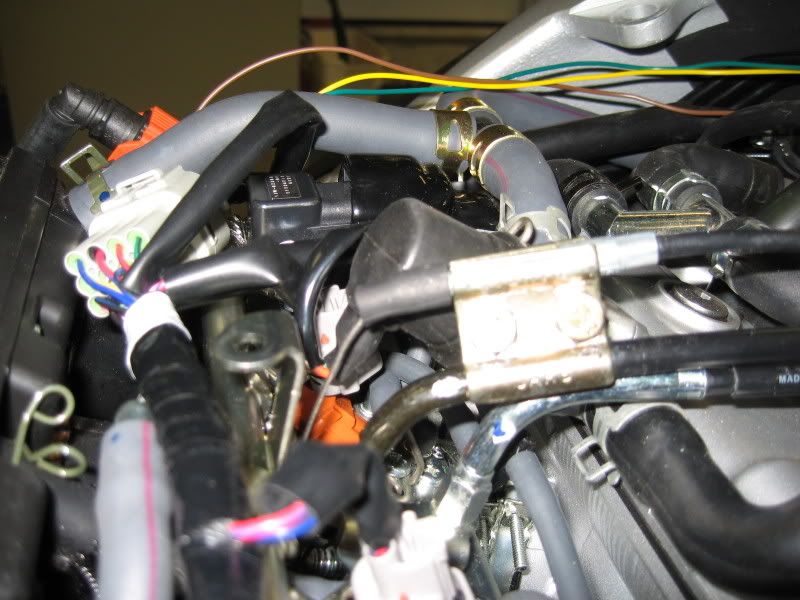

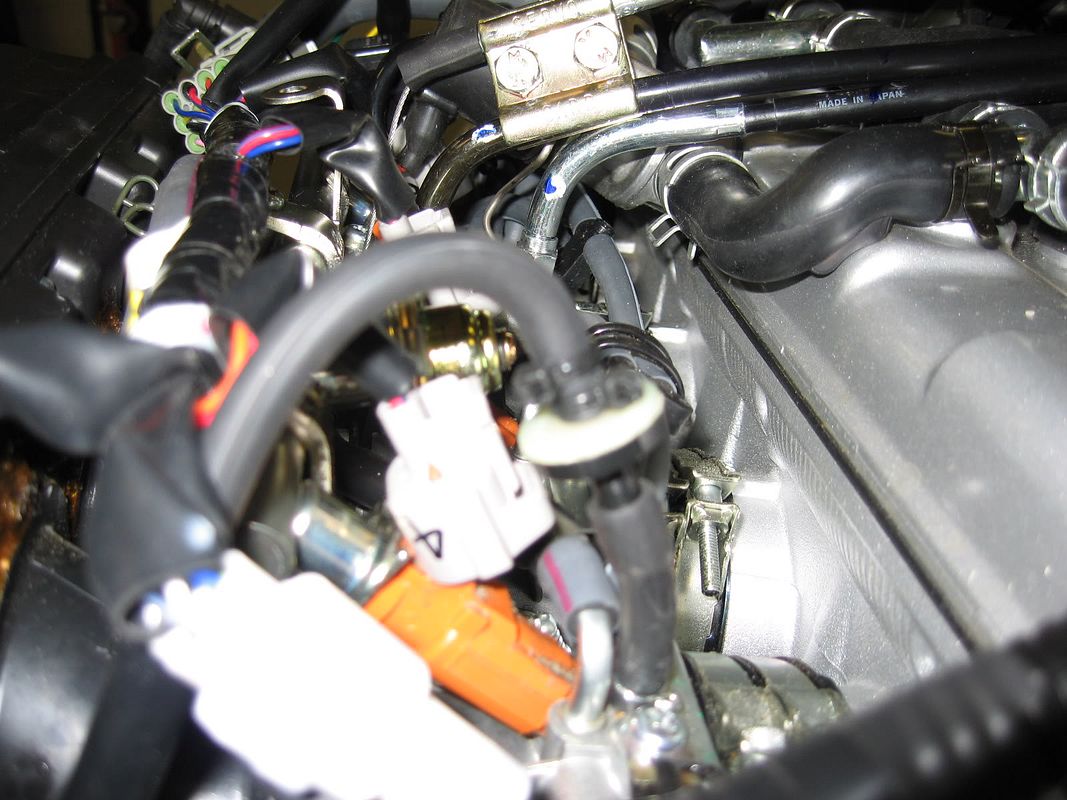

I'm in the process of installing the Audiovox cruise control and I have a little issue. I'm following the directions posted on FJRinfo.com. Bike is '06, servo will be mounted under seat. Drilled throttle tang. Installed bead chain. When I snap open the throttle to test, the chain will sometime loop under the throttle tang, preventing the throttle from fully returning. I've messed with it for about an hour, tried different set-ups and I'm still not totally comfortable. I've had stuck throttle before on dirtbikes and don't want to try that on the street. So for those of you that have installed this unit, here's a few questions; Under normal operation, does the servo cable retract when opening the throttle, even if not on cruise control? Is your bead chain adapter (the end that bolts to the throttle tang) free to rotate or is it fixed? How many beads did you use? I'm only using (5), as more seems to make the problem worse. I had to bend the throttle tang a bit to prevent the nut from catching the main throttle cable - I'm assuming you did that also.

I'm at a standstill until I get some help.........thanks in advance!

Anybody with Audiovox experience is welcomed to call me @ 423-517-0393 if you feel like lending a hand..!

Thanks,

I'm at a standstill until I get some help.........thanks in advance!

Anybody with Audiovox experience is welcomed to call me @ 423-517-0393 if you feel like lending a hand..!

Thanks,