double_entendre

Well-known member

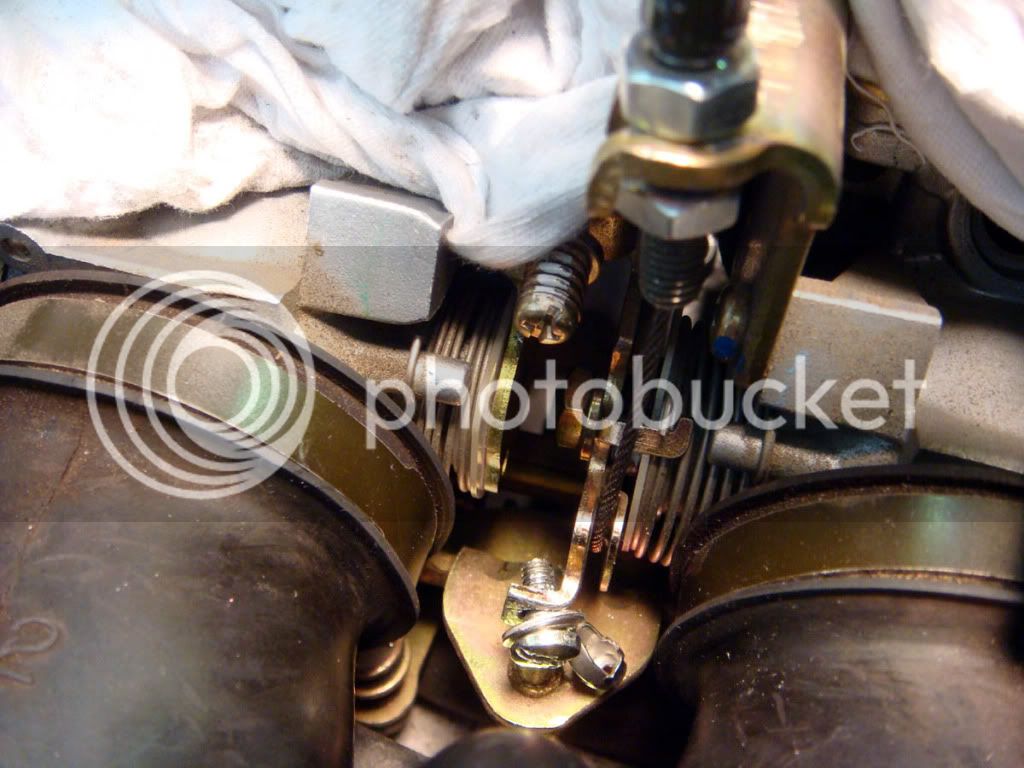

I'm trying to install the Audiovox CC onto my FJR and have managed to drill the tang so that I could put the screw into the tang and the little holder for the beaded chain. Unfortunately, I find that when I open the throttle the screw & chain holder interfere with the throttle cable at 7/8 to full throttle. See pics:

Throttle closed:

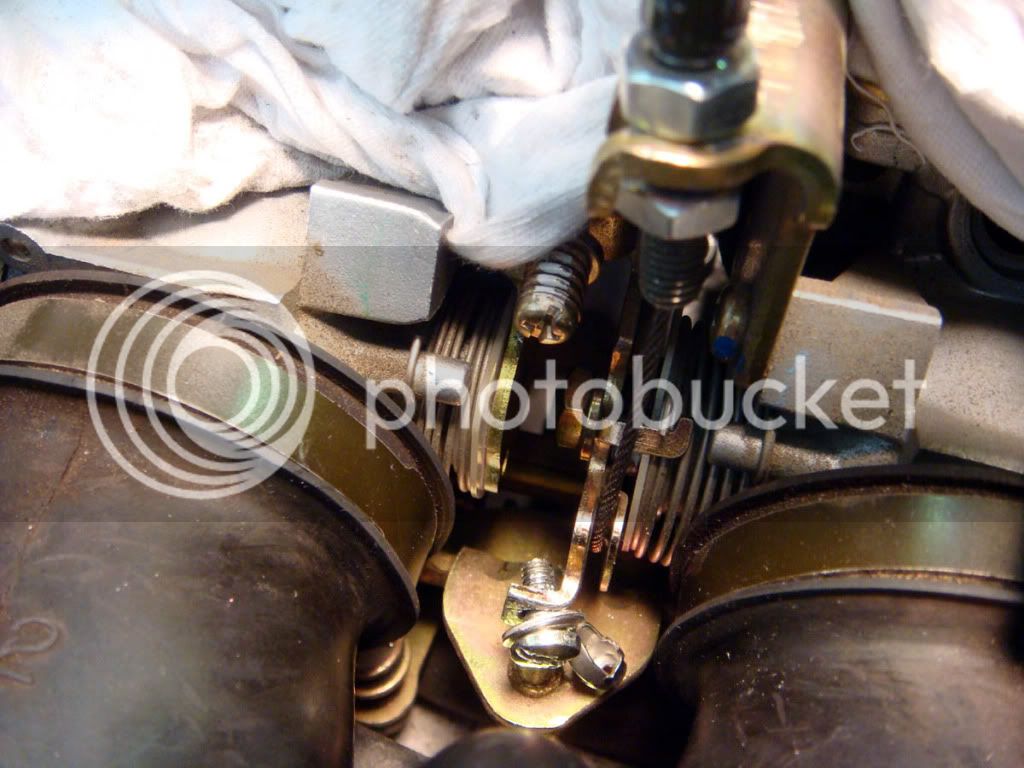

Throttle 3/4 open:

I tried bending the tang so that it would let the screw clear, but I just can't quite get it to do it and I'm hesitant to bend it too much because that little gizmo isn't a separately available part--fuck it up, buy a throttle body, it appears. :blink: I'm not even gonna price that puppy. I really don't like the interference between the cable and the bolt and bead holder--I can't imagine that won't start damaging the cable with time.

Suggestions? I'd try a smaller-headed screw and give that a go, but it seems that the OEM bolt has a bit of a shoulder to let the bead holder swing freely. I suppose I could just not tighten a smaller screw fully and use red Loctite.

I've done some Googling and haven't found anything, so once again I cast myself upon the sea of knowledge that is FJRForum.com. :clapping:

Thanks!

Rancho

Throttle closed:

Throttle 3/4 open:

I tried bending the tang so that it would let the screw clear, but I just can't quite get it to do it and I'm hesitant to bend it too much because that little gizmo isn't a separately available part--fuck it up, buy a throttle body, it appears. :blink: I'm not even gonna price that puppy. I really don't like the interference between the cable and the bolt and bead holder--I can't imagine that won't start damaging the cable with time.

Suggestions? I'd try a smaller-headed screw and give that a go, but it seems that the OEM bolt has a bit of a shoulder to let the bead holder swing freely. I suppose I could just not tighten a smaller screw fully and use red Loctite.

I've done some Googling and haven't found anything, so once again I cast myself upon the sea of knowledge that is FJRForum.com. :clapping:

Thanks!

Rancho