brazos parker

What??

Sorry, Guys, I have to vent for a moment.

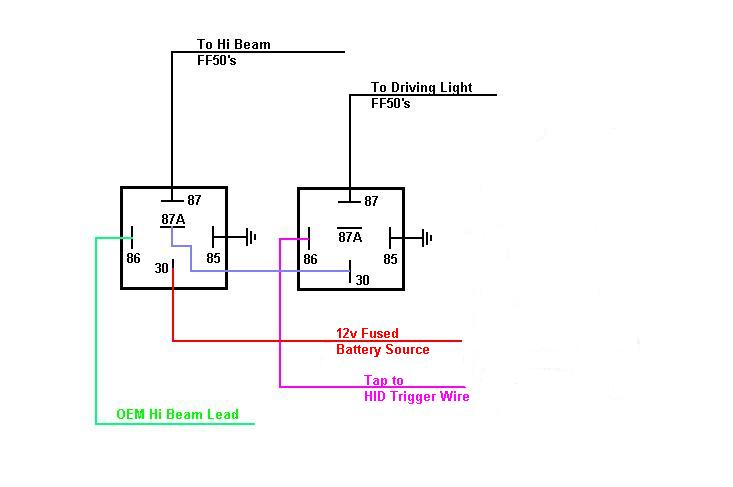

I wired up my Hella FF50's today, double checked the wiring schematic and buttoned-up the left side...over confidence showing here. Finally, I made the last connections to the Blue Sea fuse block at the rear of the bike and cranked the bike. The headlights came on...that's a good sign...hit the SPDT rocker switch one way and, then, the other...the FF50's did not light up! I checked to make sure there were bulbs in the lights and checked the 15 amp fuse in the fuse block...even took a bit of sandpaper to the fuse legs. Still no light. Damn! That was my second worst fear about this installation. The first was that I would "let the smoke out" when I tested the lights for the first time. I admit to being electrically challenged and, if all goes well, I'm OK. But, if I have to go into trouble-shooting mode...well...I'm in trouble.

So, rather than stand there a speak a few choice words, I turned off the garage lights and walked away for tonite.

Tomorrow, I'll trace all the wiring again...3rd or 4th time...but, at this point, I'm suspecting the Hella relay is bad or the Dual Star rocker switch is bad. However, it's more likely that I've screwed the pooch along the way. I hate it when that happens!

I wired up my Hella FF50's today, double checked the wiring schematic and buttoned-up the left side...over confidence showing here. Finally, I made the last connections to the Blue Sea fuse block at the rear of the bike and cranked the bike. The headlights came on...that's a good sign...hit the SPDT rocker switch one way and, then, the other...the FF50's did not light up! I checked to make sure there were bulbs in the lights and checked the 15 amp fuse in the fuse block...even took a bit of sandpaper to the fuse legs. Still no light. Damn! That was my second worst fear about this installation. The first was that I would "let the smoke out" when I tested the lights for the first time. I admit to being electrically challenged and, if all goes well, I'm OK. But, if I have to go into trouble-shooting mode...well...I'm in trouble.

So, rather than stand there a speak a few choice words, I turned off the garage lights and walked away for tonite.

Tomorrow, I'll trace all the wiring again...3rd or 4th time...but, at this point, I'm suspecting the Hella relay is bad or the Dual Star rocker switch is bad. However, it's more likely that I've screwed the pooch along the way. I hate it when that happens!