UselessPickles

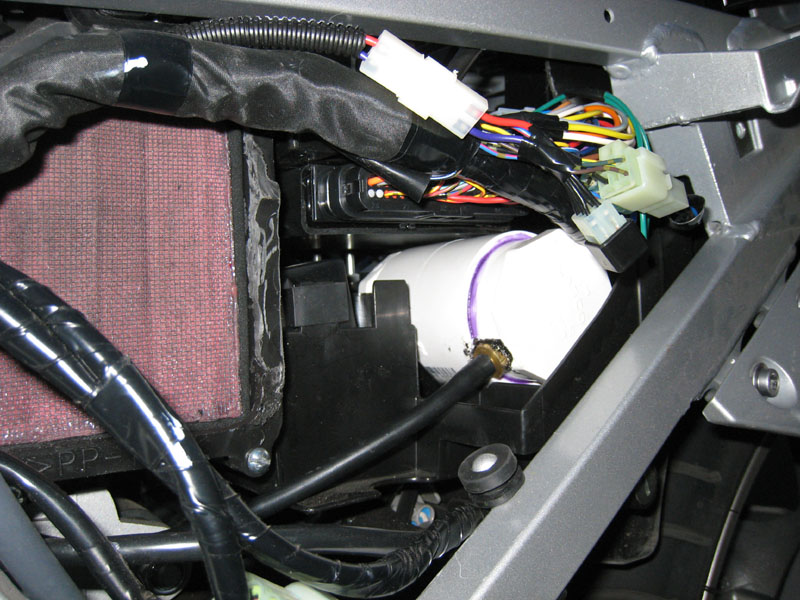

Making Grand Canyon replicas from air boxes...

What are some cases where it could cause problems, and how bad would the problems be?For future reference connecting the ground (-) circuit to the frame is not recommended but it'll work in most cases.

The frame is not a component of any electrical circuits. You'll notice in the FJR's wiring schematics that a return wire (usually black or some variation) is routed throughout the wiring harness. This is the common (-) side of most circuits.

The engine crankcase is an electrical conductor since the battery's negative post is connected to the engine. The frame will conduct electricity because it's bolted to the engine at several places. But having current flow from the engine to the frame is not recommended.

The FJR-specific powerlet kit that I have also uses a bolt on the frame for the ground connection.